How to choose a sachet packaging machine

1、Horizontal sachet packaging machine VS vertical sachet packaging machine

2、China horizontal sachet packing machine VS Italian machine?

1-1、Difference between horizontal sachet packing machine and vertical sachet packing machine

* * Structural Design * *

-* * Horizontal pouch packing machine * *:

-The material handling and packing process is carried out in the horizontal direction.

-The equipment structure is relatively complex and occupies a large area.

-Suitable for materials with poor fluidity or requiring gentle handling.

-* * Vertical pouch packing machine * *:

-The material handling and packing process is carried out in the vertical direction.

-The equipment is compact and occupies a small area.

-Suitable for materials with good fluidity.

2. * * Applicable Material * *

-* * Horizontal pouch packing machine * *:

-Suitable for materials with poor fluidity, fragile or requiring high precision packaging.

-* * Typical products * *: pesticides, fertilizers, single-dose packaging (requiring precise metering and leak-proof design), cosmetics (such as masks, lotions), health products ,such as chocolate protein smoothie, protein powder, etc.

-* * Vertical pouch packing machine * *:

-Suitable for materials with good fluidity and uniform particles.

-* * Typical products * *: candy, nuts, washing powder, condiments, instant drinks, etc.

3. * * Packing accuracy * *

-* * Horizontal sachet packing machine * *:

-High packaging precision, suitable for products with strict measurement requirements (such as pesticides, fertilizers, medicines, etc.).

-* * Vertical pouch packing machine * *:

-The packaging speed is fast, but the accuracy is relatively low, which is suitable for products with low measurement requirements.

4. * * Packing speed * *

-* * Horizontal pouch packing machine * *:

-Slower, but better for high quality, high precision packaging needs.

-* * Vertical pouch packing machine * *:

-Fast speed, suitable for mass production.

5. * * Floor Space * *

-* * Horizontal pouch packing machine * *:

-Larger footprint but easier to operate and maintain.

-* * Vertical pouch packing machine * *:

-Small footprint for production environments with limited space.

6. * * Automation * *

-* * Horizontal pouch packing machine * *:

-Highly automated, suitable for continuous production and packaging with high quality requirements.

-* * Vertical pouch packing machine * *:

-High degree of automation, but relatively simple structure.

1-2、Why do Europe and the United States like the horizontal machine, while Southeast Asia likes the vertical pouch machine?

1-2-1、Reasons why the European and American markets prefer horizontal machines:

1. * * High Quality Requirements * *:

-The European and American markets have high requirements for packaging accuracy and quality, especially for pesticides, fertilizers, medicines and other products requiring accurate measurement.

-The horizontal machine has more advantages in packaging precision and leak-proof design.

2. * * Production environment * *:

-European and American factories usually have more space and can accommodate the larger footprint of a horizontal machine.

3. * * Automation Requirements * *:

-Europe and the United States have high labor costs and prefer high automation equipment to reduce manual intervention.

4. * * Strict regulations * *:

-Europe and the United States have strict regulations on the packaging of pesticides, fertilizers, pharmaceuticals and other products, and horizontal machines are easier to meet these standards.

1-2-2、Reasons why Southeast Asian markets prefer vertical machines:

1. * * Cost Sensitive * *:

-The Southeast Asian market pays more attention to equipment cost and cost performance, and the price of vertical machines is lower, which is suitable for enterprises with limited budget.

2. * * Productivity * *:

-Vertical machines are fast and suitable for mass production to meet the demand for efficiency in the Southeast Asian market.

3. * * Space restrictions * *:

-Southeast Asian factories usually have limited space, and vertical machines have a small footprint, which is more suitable for the local production environment.

4. * * Product Type * *:

-The Southeast Asian market produces more food, daily necessities and other products that do not require high packaging accuracy, and the vertical machine can fully meet the demand.

2、Difference between China sachet packing machine and Italian machine

2-1、Advantages of Migrand Horizontal Sachet Packing Machine

1. * * Cost advantage * *:

-The horizontal pouch packing machine in China is more competitive in manufacturing cost, the price is lower than the Italian machine, and the cost performance is higher.

2. * * Customized Services * *:

-China factory can be highly customized according to customer needs to meet the special packaging needs of different products (such as leak-proof design of pesticides and fertilizers).

3. * * Technical support and after-sales service * *:

-Provide comprehensive technical support and after-sales service to ensure the long-term stable operation of the equipment.

4. * * Quality and Performance * *:

-Migrand's horizontal pouch packaging machines have reached or surpassed Italian machines in terms of quality and performance, especially in the field of single-dose packaging of pesticides and fertilizers.

5. * * Flexibility * *:

-Flexible equipment design can quickly adapt to the packaging needs of different products and reduce the production adjustment time of customers.

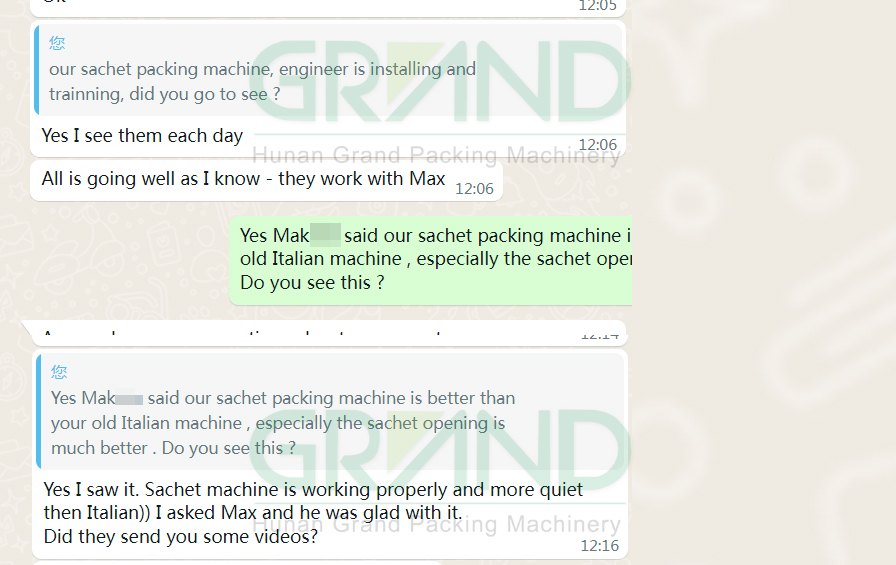

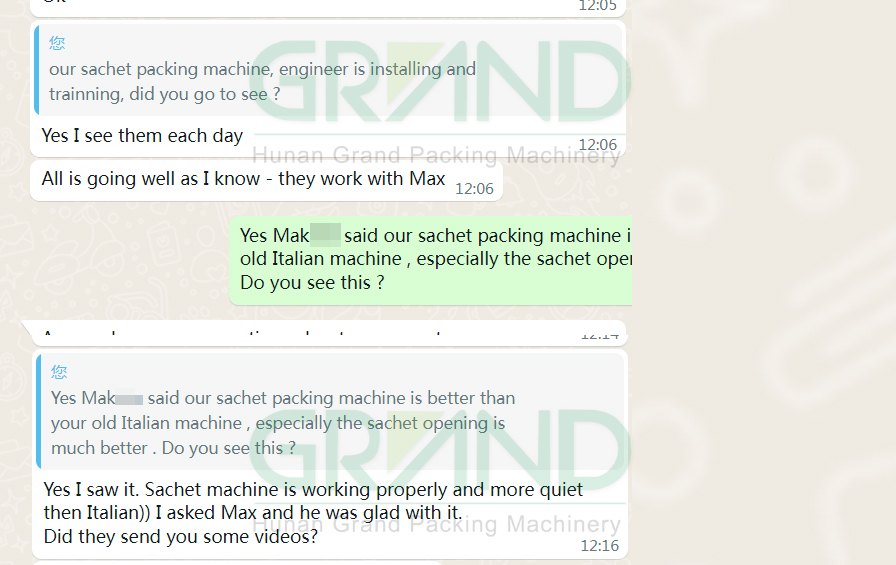

2-2、Is the Chinese horizontal sachet packaging machine really better than the Italian machine?

1. * * Value for money * *:

-China machines are more advantageous in price, while their performance and accuracy are not inferior to those of Italian machines.

2. * * Customization capability * *:

-Customization services in China are more flexible and can respond quickly to customer needs, while Italian machines are usually more standardized, and customization costs and time are longer.

3. * * Localization Services * *:

-Chinese factories can provide more timely after-sales service and spare parts support, while Italian machines have slower response time in after-sales service, and the cost of spare parts is very high, which is unacceptable for factories that need timely response.

4. * * Technological Innovation * *:

Migrand's horizontal sachet packaging machine has made continuous progress in technological innovation, especially in special fields such as pesticides and fertilizers, and has accumulated rich experience.

3、Sum up

-* * Horizontal sachet packaging machine * *

-It is suitable for high-precision and high-quality packaging (such as pesticides, fertilizers, medicines, cosmetics, etc.),

while vertical sachet packaging machine is suitable for large quantities of products with good liquidity (such as food, daily necessities, etc.).

-European and American markets prefer horizontal machines because of their high requirements for packaging accuracy and quality, while Southeast Asian markets prefer vertical machines because of their low cost and high efficiency.

-Chinese's horizontal sachet packaging machines have significant advantages in terms of cost, customized service, technical support and quality performance, and can indeed be comparable to or even surpass Italian machines, especially in the field of single-dose packaging of pesticides and fertilizers.

English

English