1. Application

It is suitable for the two lanes sachet filling and packing for paste, cream, gel or liquid, such as shampoo, hand sanitizer gel, cream, sauce etc.

This machine is automatic packing machine processing two rolls of film on two lanes. It is installed with two kinds of pump, piston pump or needle valve pump, which would be chosen on clients’ request, the piston pump is for paste and the needle valve pump for liquid.

2. Features

1) Sachet-making, measuring, filling, sealing, cutting and counting are all finished automatically.

2) By either length control or photo-electronic color tracking, clients can set sachet length and cut in one step and save time and film.

3) The temperature is under independent PID control, more suitable for different packing materials.

4) The driving system is simple and reliable, and maintenance is easy.

5) Applicable material should be composite films like: PET/PE, Paper/PE, PET/AL/PE, OPP/PE.

3. Machine picture

4. Technical specifications

Machine | Automatic liquid Packing Machine |

Model | DCJJ-300(Two lane on Pneumatic types) |

Sealing type | 4 side sealed bag |

Measurement | Piston pump 5-30ml |

Cutting type | straight cutter with tear notch |

Control | PLC Touch screen |

Sealer | Horizontal sealer&Vertical sealer :Line pattern |

Speed | 70-110 sachets/min (two lanes) |

Sachet size | Length: 30-150mm Width: 10-80mm |

Total power | 3000W |

Voltage | 220V 50Hz 1P(can be customized) |

Weight | 400Kg |

Machine size | L*W*H: 1500*740*1800mm |

Material | Contacting parts SUS304 |

Includes | Inverter, two photo sensor, two date code ribbon printer, one piston pump set and one needle valve pump, horizontal stirrer inside the hopper with a lid, two sachet former, interlock safety door. |

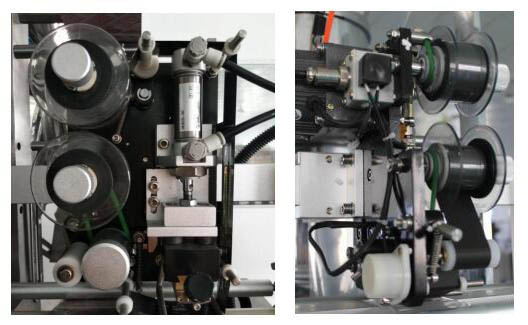

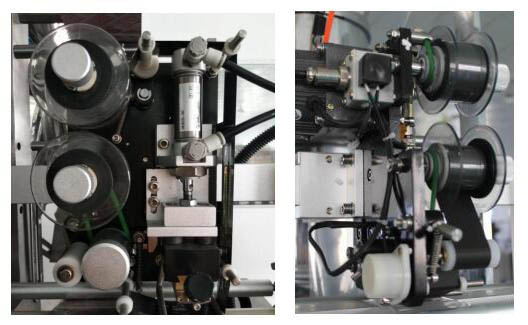

Paste dosing system – piston pump

Liquid dosing system– Needle valve suction pump

It is volume way not weigh. Clients can get different volume (ml) after pump adjusted.

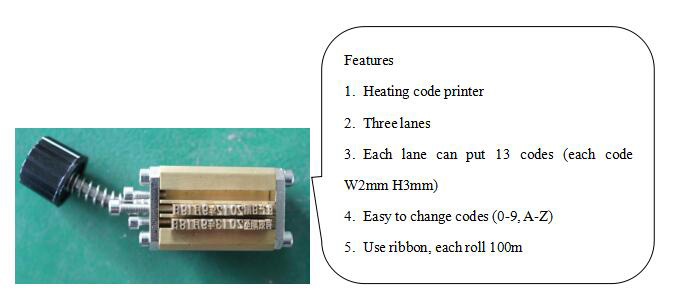

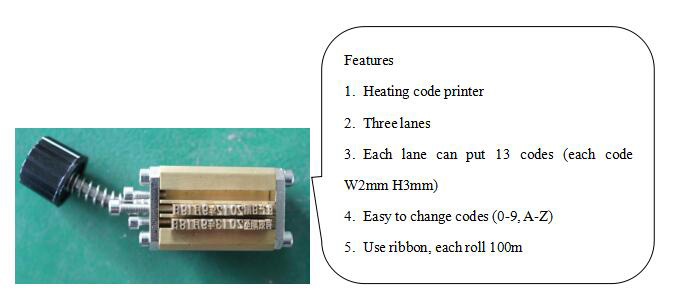

Date coding ribbon printer

5. Sample

Our Services

Service 3: We will dispatch engineers to your site for machine installation and commissioning, and also do the training for your technicians.

Service 4: We makes guarantee of the machine for 12 (twelve) months. During this Warranty period, the seller will provide free spare parts that cause by the machine’s quality within 10 days by fast courier upon receipt of buyer’s notice.(we will also provide one set of spare parts /wear &tear parts to customer along with the shipment of the machine.

Service 5: We warmly welcome the suggestions from customer to make us grow better and produce better machine along with providing better service to customer, and create more value for customer.

Service 6: Before placing the order or before shipping, welcome to our factory to take a visit to inspect our machine. we will pick you up in the airport or train station and arrange your following schedule in our city to bring you a nice journey during this visit.

Company Information

ABOUT US

Hunan Grand Packing Machinery Co.,Ltd is specialized in the pharmaceutical and packing machinery for more than 10 years, such as plastic ampoule forming filling and sealing machine, capsule filling machine, blister packing machine, strip packaging machine, cartoning machine etc. We have provided services and machines to many different countries and regions in the whole world, such as Indonesia, Thailand, Malaysia, Philippines, New Zealand, Korea,the Middle East area, Poland, Belgium, France, UK, Greece, Italy, Turkey, USA, central and south America such as Trinidad and Tobago,Mexico, Brazil, Russia, Ukraine, UZ, Tunisia, Algeria, Morroco etc. And we always gain the good reputation from customer both from the machine quality and after sales service.

customer visit at our factory and our visit to customer

Our factory

We are cooperating with various kinds of factories and companies in different fields, including pharmaceutical factory, food factory, supplement factory, agrochemical factory such as for pesticide, fertilizer, personal care product factory, such as for cosmetic product, daily use product, stationery factory, hardware factory etc.

English

English