DXDO-J900E sachet filling and packing machine, it is the high speed sachet filling and packaging equipment mostly applied in pharmaceutical, cosmetic, food, daily chemical necessities products, for example, we have rich experience in filling and packing for honey, ketchup, hand sanitizer, marmalade, different kinds of fruit jam, chilli sauce, hair shampoo, facial cream and so on.

The machine can fulfill the following working process:

Packing material unwinding --sachet forming--product feeding and filling--sachet heat sealing--batch No embossing or printing--cutting and final product output. We can also customize the machine for you if you have any special requirement.

1. Features

1) This machine features high efficiency, high power, low noise, simple maintenance and longer service life;

2) It applies roller heat sealing, four side sealing, high speed and multi-line packing. Sachets can be manufactured smoothly so that production efficiency can be improved;

3) Easy adjustment, precise measurement. Only simple procedures are needed for sachet length adjustment without changing mould. Advanced technologies of HMI makes this machine to seal and cut horizontally and vertically, fill and notch cut automatically;

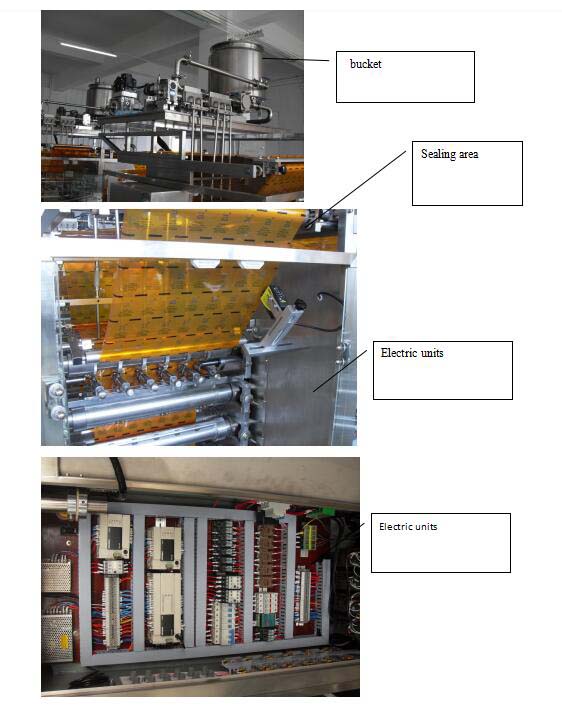

4) the machine applies servo motor and PLC from famous brands. Touch screen makes sachet length to be set directly. Meanwhile, auto in-phase tracking is applied for horizontal and vertical sealing. Besides, this machine saves more time and material, pulls sachets more smoothly and is adjusted more conveniently, compared with machine of mechanical transmission;

5) Accuracy in page correcting, automatic counting, and photoelectric tracking system is adopted to ensure the automatic correcting; double face printing on packing sachets, precise counting.

6) It perform reliably, is operated conveniently and automatically performance. PLC is used for automatic control and frequency converter for stepless speed adjustment.

7) Most complex film can be used as packing materials on this machine.

2. Usage

It is suitable to pack catsup materials in the fields of pharmacy industry, food industry and daily industry, such as ketchup, shampoo, honey, jam, cream of all kinds.

3. Main technological parameter

Sachet length | 50-300mm(L) (adjustable) |

Sachet width | 36-100mm(W) (unchangeable) |

Packing speed | 300-400 sachets/min (8lines) depend on sachet size and material |

Measuring range | 2-100ml |

Cutting mode | Flat cutting, with easy tear port |

Sealing mode | 4 side sealing |

Applicable film | PET/AL/PE, PET/PE, NY/AL/PE, NY/PE |

Max width of film roll | 900mm |

Max film roll diameter | Φ300mm |

Film roll core diameter | Φ76 mm |

Power supply | 380V, 3 phase, 4 wires, 50HZ |

Power | 12KW |

Machine packing dimensions | (L)1650mm*(W)1400mm*(H)2200mm |

G.W | 1500KG |

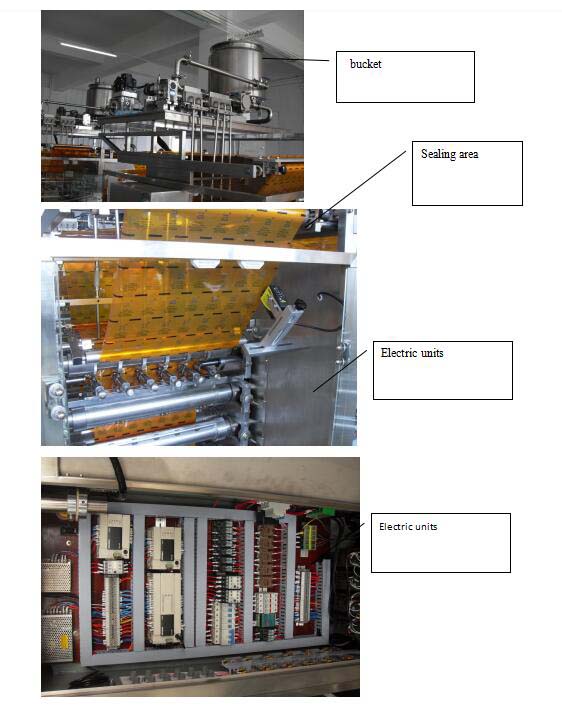

4. Pictures

1) Hopper and pump

2) Samples

Our Services

Service 3: We will dispatch engineers to your site for machine installation and commissioning, and also do the training for your technicians.

Service 4: We makes guarantee of the machine for 12 (twelve) months. During this Warranty period, the seller will provide free spare parts that cause by the machine’s quality within 10 days by fast courier upon receipt of buyer’s notice.(we will also provide one set of spare parts /wear &tear parts to customer along with the shipment of the machine.

Service 5: We warmly welcome the suggestions from customer to make us grow better and produce better machine along with providing better service to customer, and create more value for customer.

Service 6: Before placing the order or before shipping, welcome to our factory to take a visit to inspect our machine. we will pick you up in the airport or train station and arrange your following schedule in our city to bring you a nice journey during this visit.

Company Information

ABOUT US

Hunan Grand Packing Machinery Co.,Ltd is specialized in the pharmaceutical and packing machinery for more than 10 years, such as plastic ampoule forming filling and sealing machine, capsule filling machine, blister packing machine, strip packaging machine, cartoning machine etc. We have provided services and machines to many different countries and regions in the whole world, such as Indonesia, Thailand, Malaysia, Philippines, New Zealand, Korea,the Middle East area, Poland, Belgium, France, UK, Greece, Italy, Turkey, USA, central and south America such as Trinidad and Tobago,Mexico, Brazil, Russia, Ukraine, UZ, Tunisia, Algeria, Morroco etc. And we always gain the good reputation from customer both from the machine quality and after sales service.

customer visit at our factory and our visit to customer

Our factory

We are cooperating with various kinds of factories and companies in different fields, including pharmaceutical factory, food factory, supplement factory, agrochemical factory such as for pesticide, fertilizer, personal care product factory, such as for cosmetic product, daily use product, stationery factory, hardware factory etc.

English

English