New machine  | Old machine  |

The whole appearance is exquisite and concise | The old machine is cumbersome and complicated |

Details comparison |

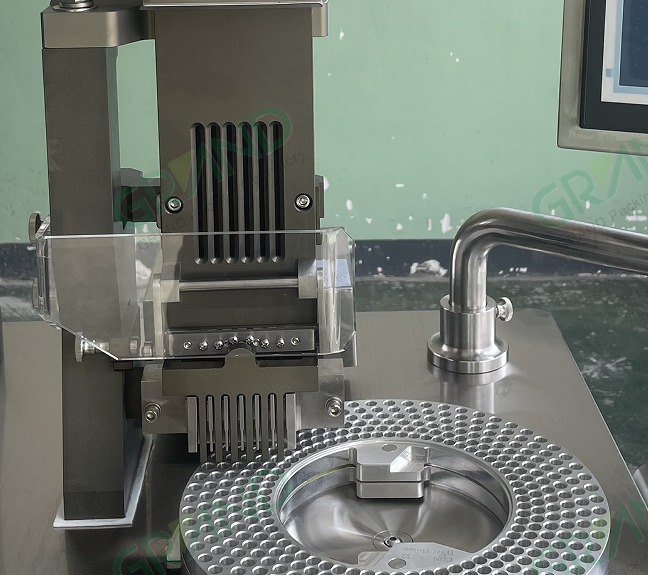

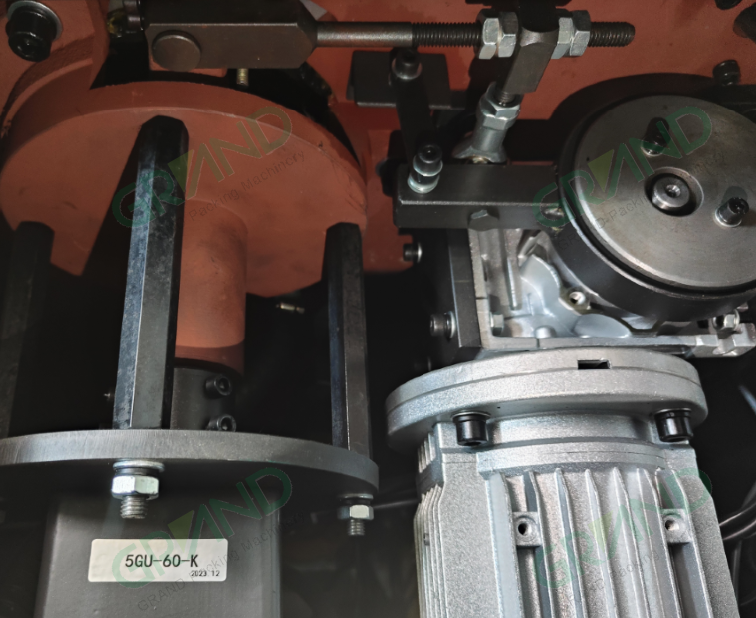

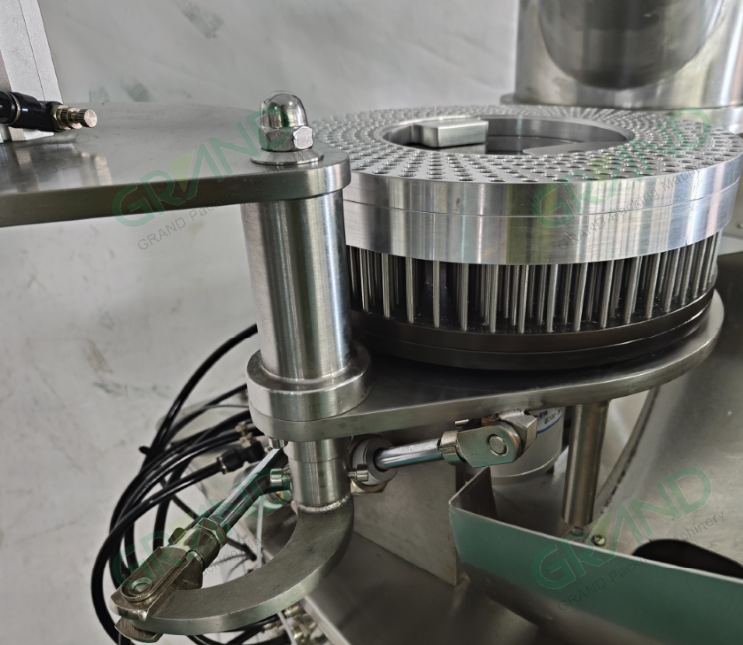

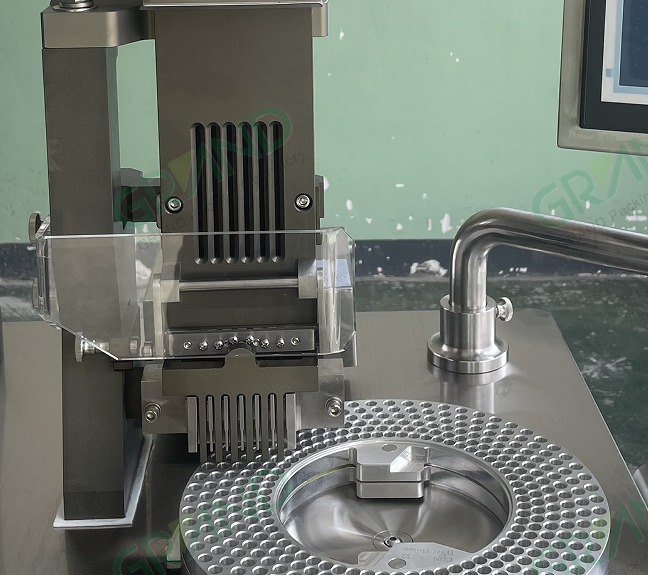

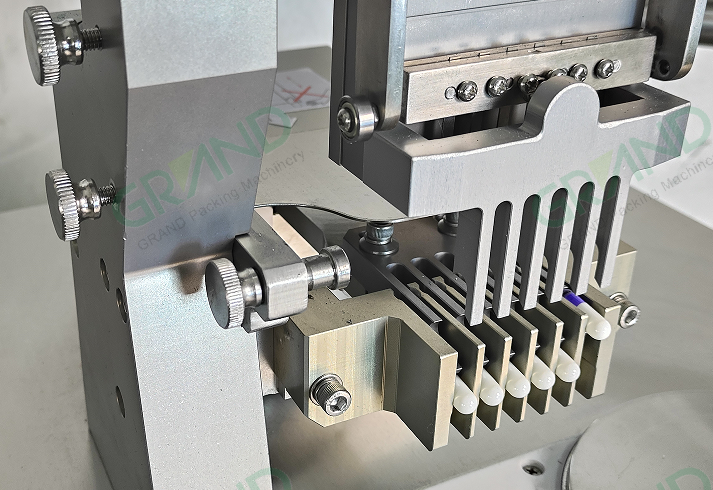

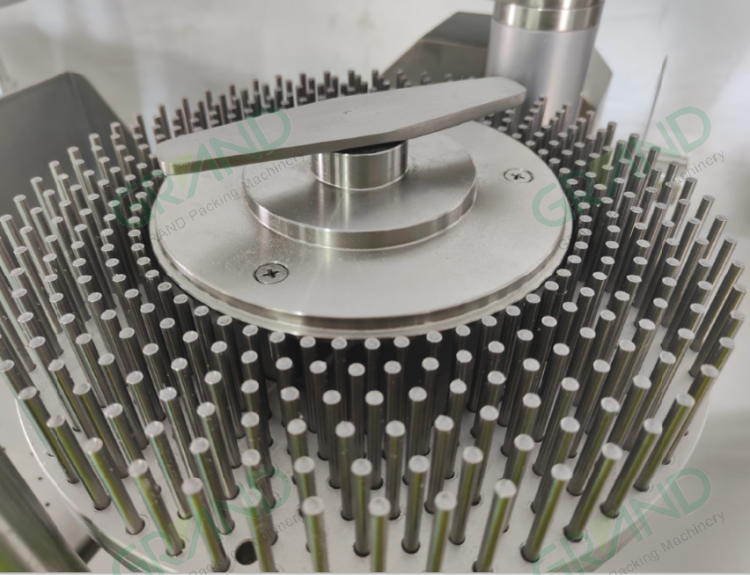

New capsule seeding mechanism

| Old capsule seeding mechanism

|

It adopts a more user-friendly independent support and power separation design, for simple structure, convenient debugging and more silent operation. | The old structure is bulky and heavy with loud noise during operation, which is inconvenient for debugging and cleaning. |

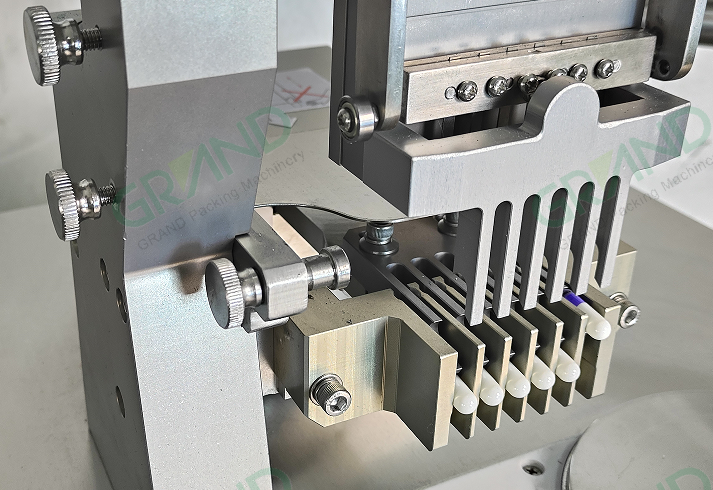

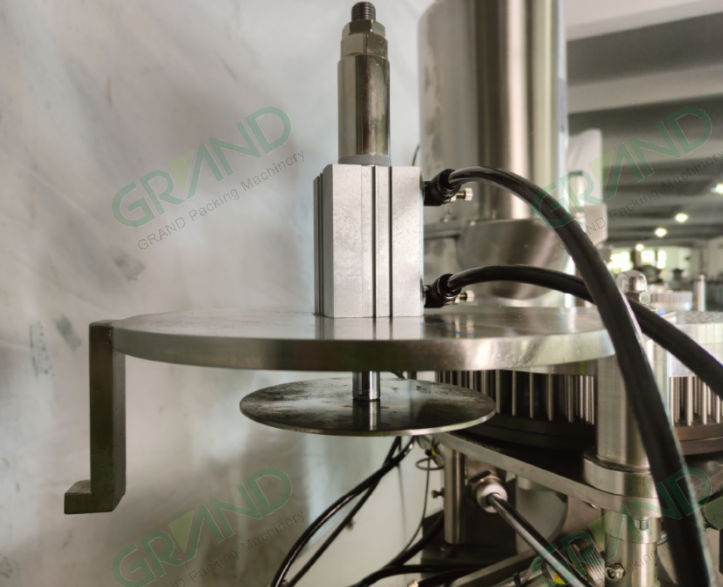

New capsule seeding switch

| Old capsule seeding switch

|

The control switch of linear track type is more convenient and accurate to adjust the opening position of the capsule control bracket. | The old structure needs to adjust the arc through two fixed screws, which is inconvenient to operate. |

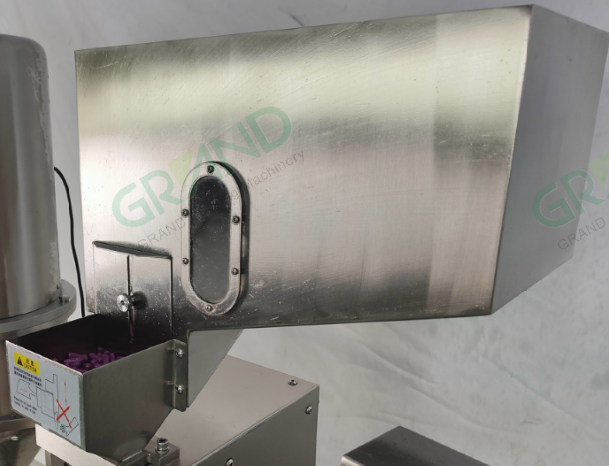

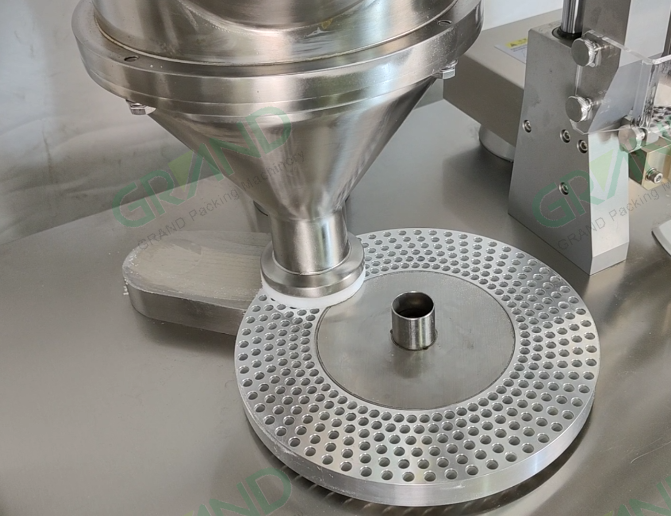

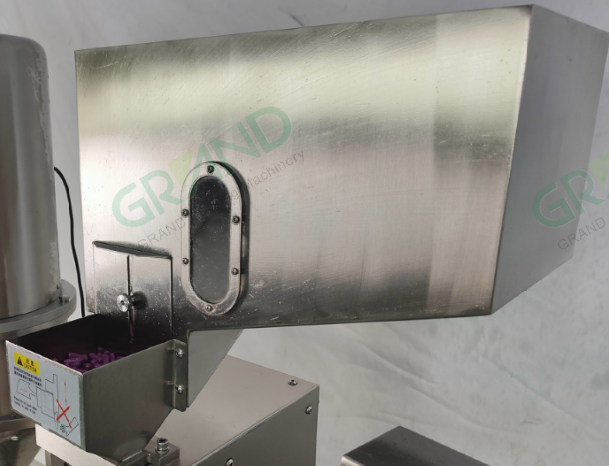

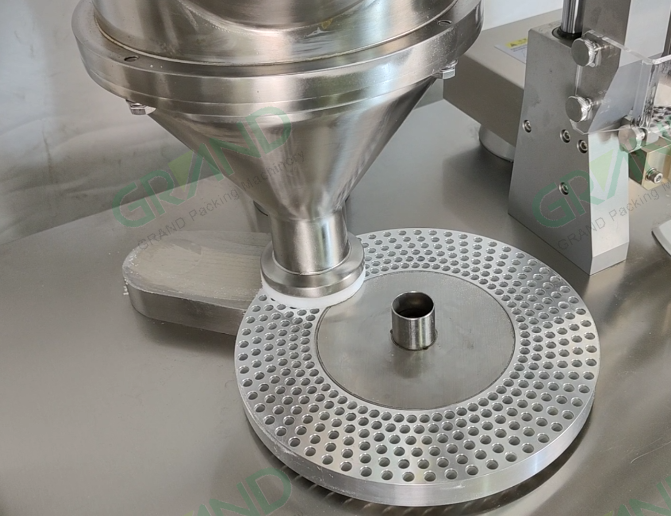

New capsule hopper

| Old capsule hopper

|

Adopts quick-positioning device for quick positioning and disassembly without tools, and it is not easy to leave the capsule in the hopper. | The old hopper is not so convenient to assemble and disassemble, and there are dead corners for cleaning. |

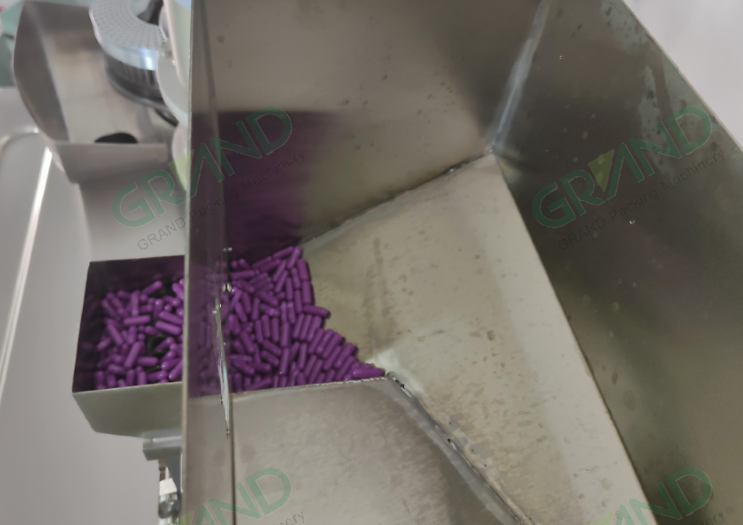

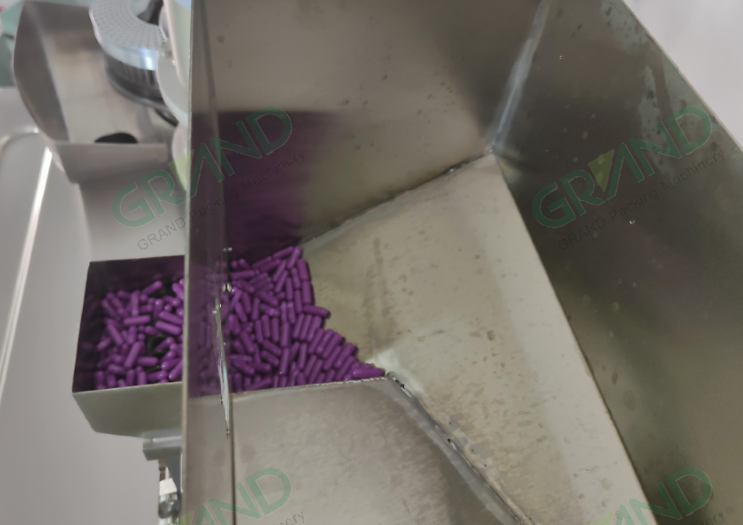

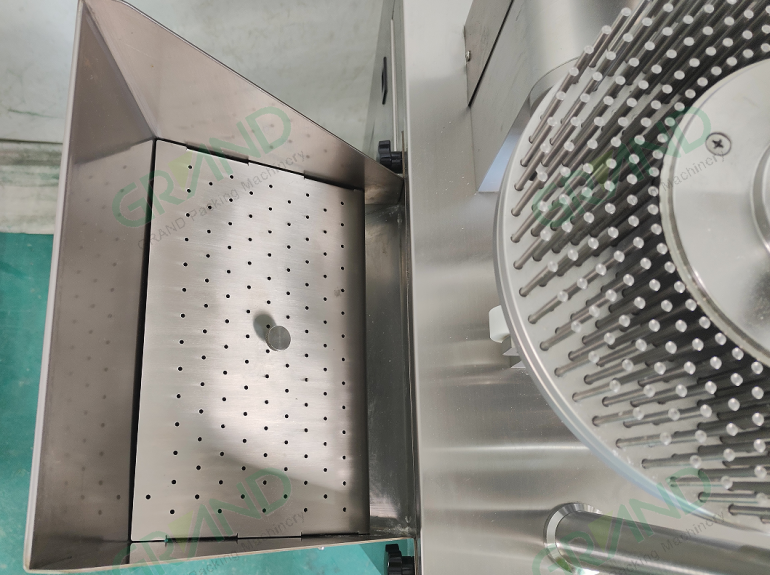

New sub-hopper

| Old sub-hopper

|

It is equipped with a shutter, the front plate can be opened for convenient capsule cleaning. | It can’t be opened but only be disassembled entirely for cleaning. |

Design and structure |

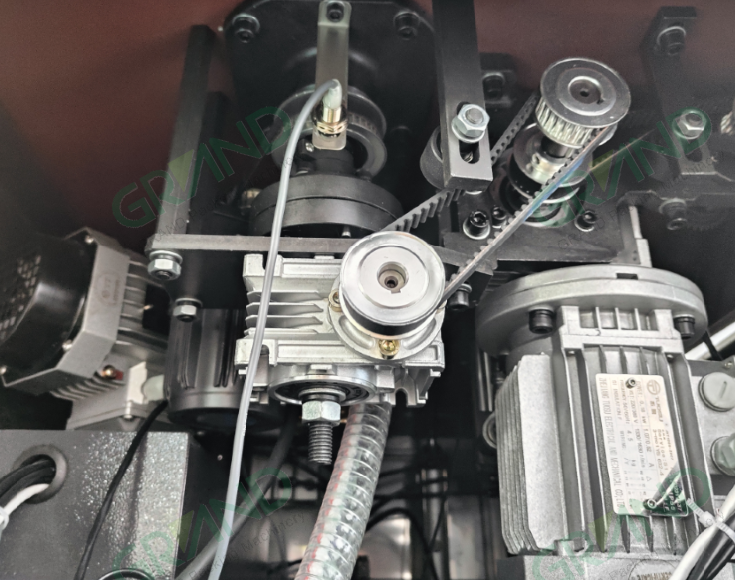

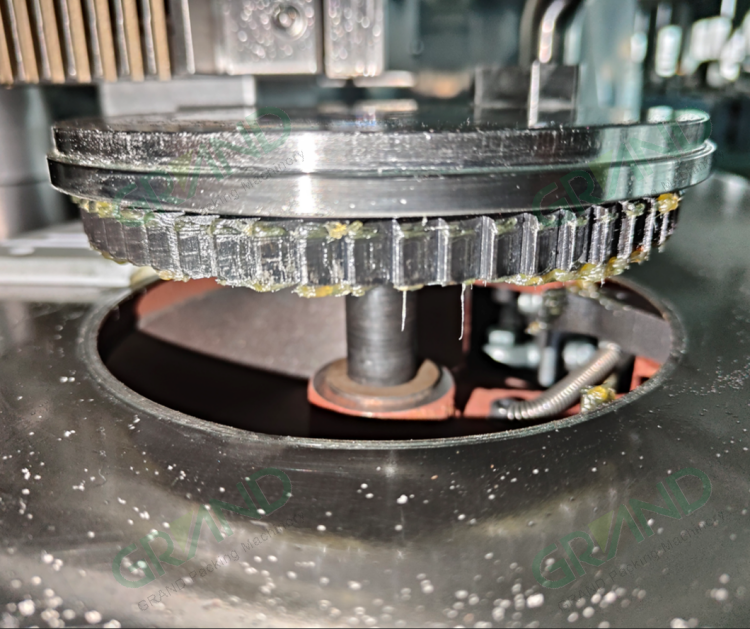

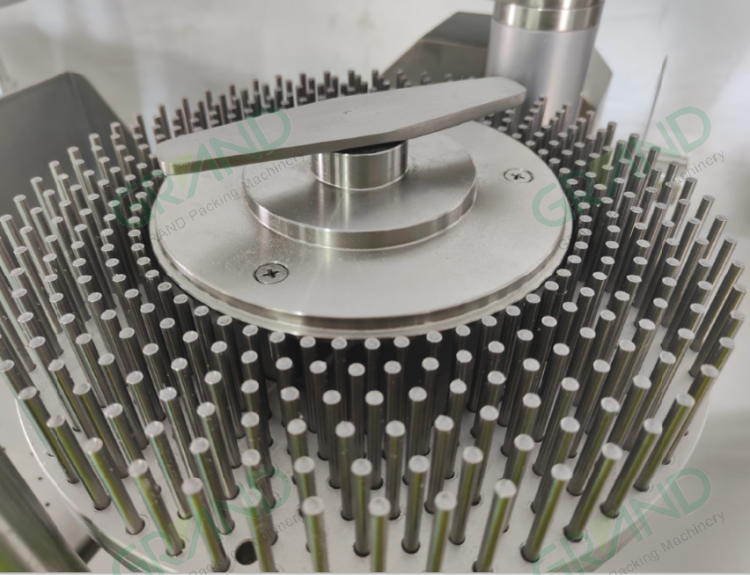

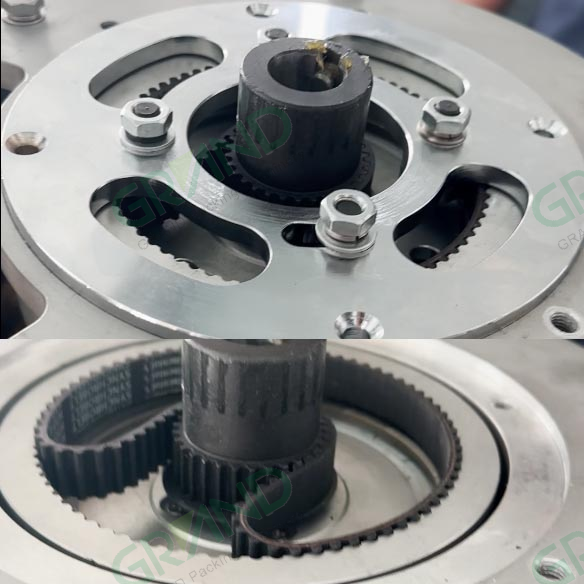

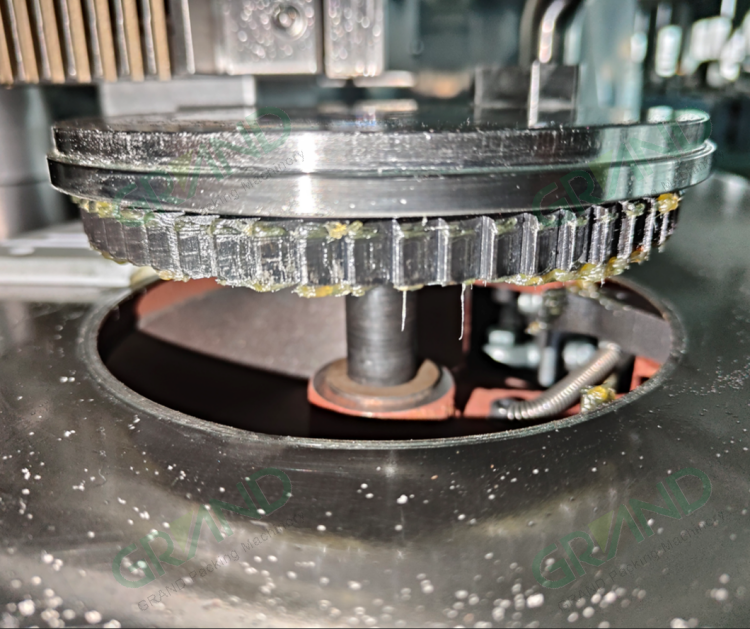

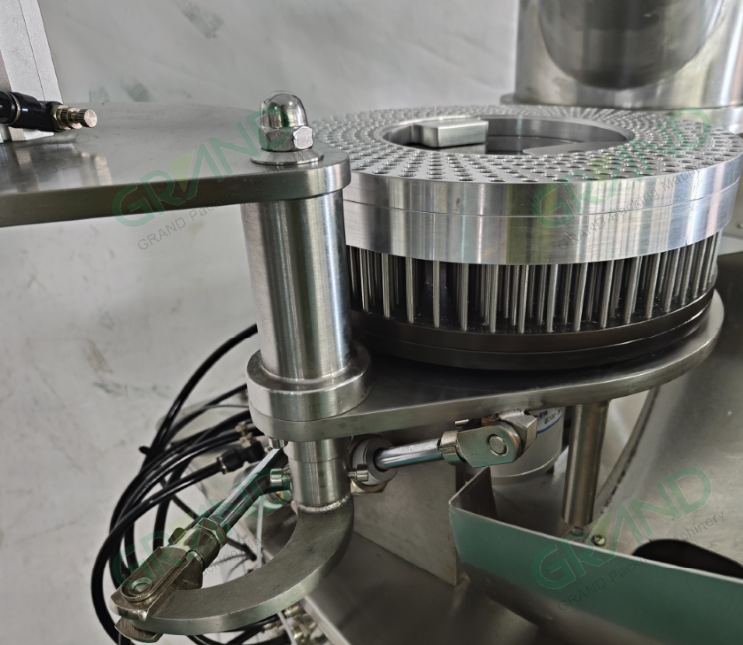

New capsule ring mechanism

| Old capsule ring base

|

Linkage operation of high speed 25% and stable, the base adopts oil-proof and dust-proof design to reduce noise 90% and maintenance frequency. | The turntable base works intermittently with more noisy, and is not dustproof, so the powder will stick to the ratchets and aggravate wearing. Oil penetration, powder contamination. |

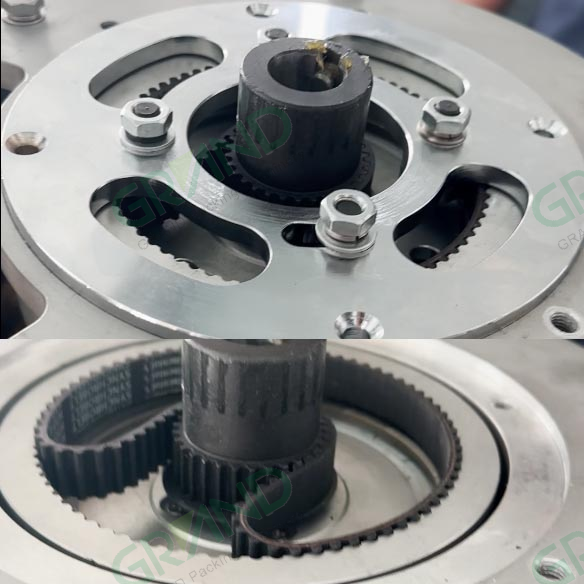

Capsule filling and locking |

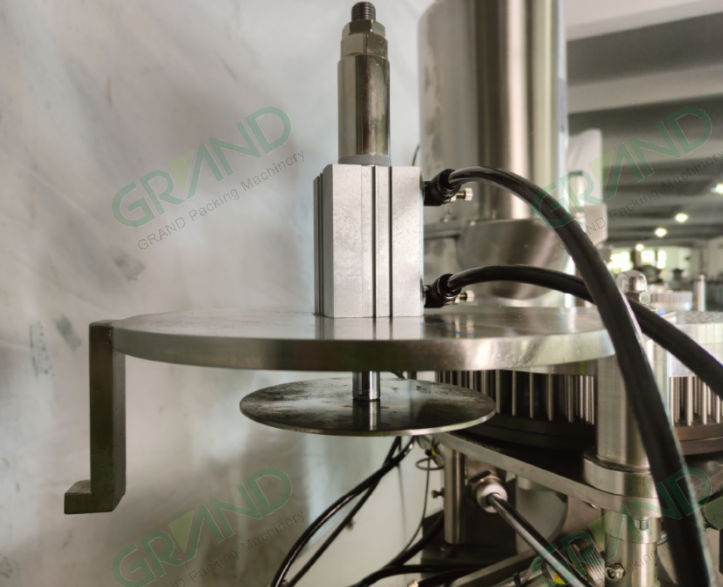

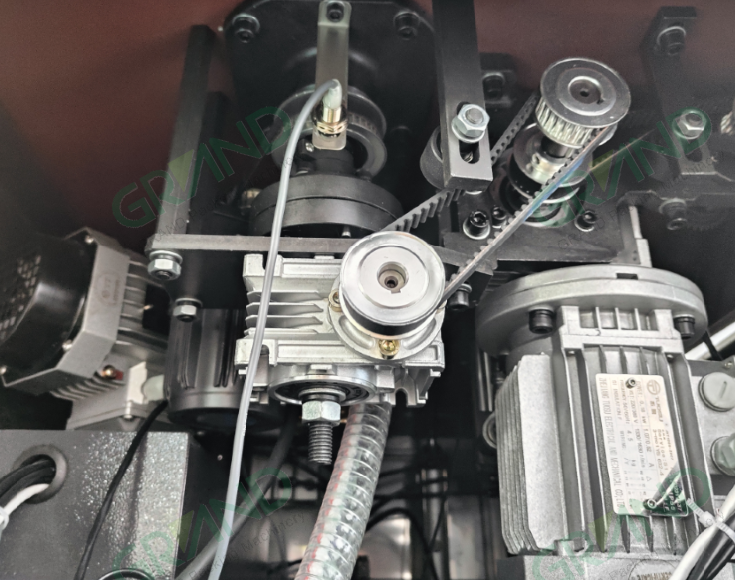

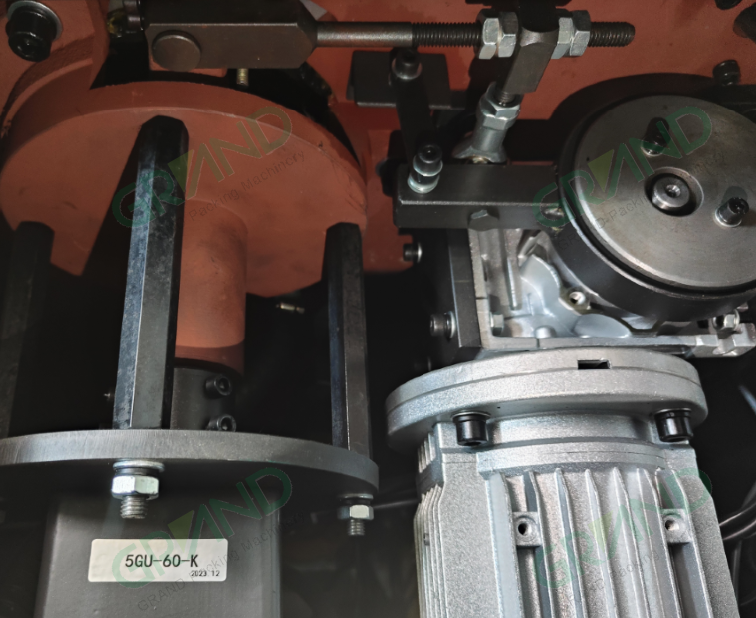

New capsule filling station

| Old capsule filling station

|

The new filling power adopts synchronous belt planetary deceleration and multi-stage positioning design for more stable and silent filling. | The old filling power adopts gear-type planetary mechanism with low transmission ratio. |

New capsule locking station | Old capsule locking station  |

With built-in cylinder and air pipe, more concise and safer, the new capsule locking structure is more reasonable locking action and low failure rate. | Old capsule locking structure is bloated, the wire, air tube and sensor are external, easy to entangle; The opening and closing structure design is unreasonable and easy to be damaged. |

Capsule discharging |

New capsule discharge mechanism

| Old capsule discharge mechanism

|

Safety device for capsule discharge, all the power worked under the platform. | The cylinder and air tube adjusting device are exposed. |

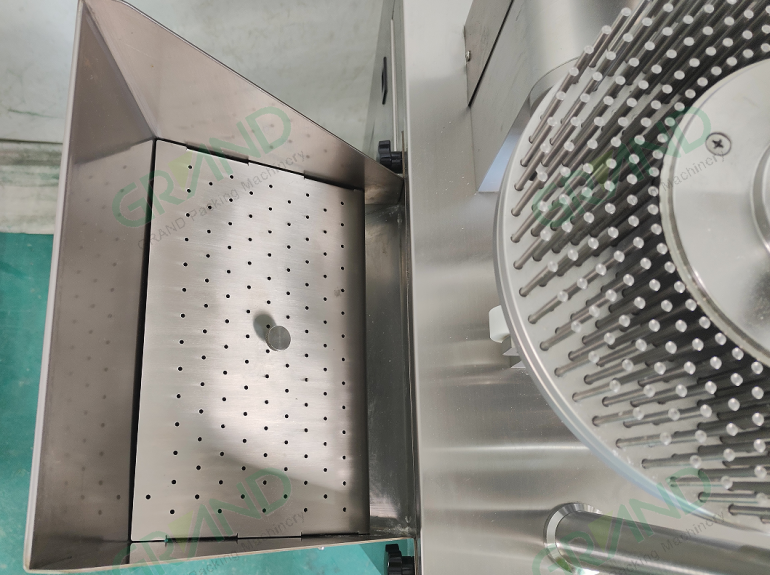

New capsule discharge hopper

| Old capsule discharge hopper

|

Split design and placed outside of the machine, for quick disassembly and easy cleaning, features powder sieving function. | Built-in structure, inconvenient to maintain, disassemble and clean. |

Maintenance |

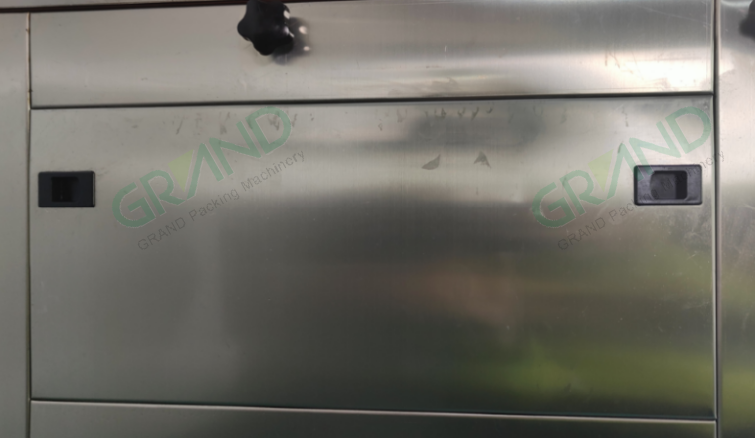

Maintenance port to discharge mechanism

| No maintenance port

|

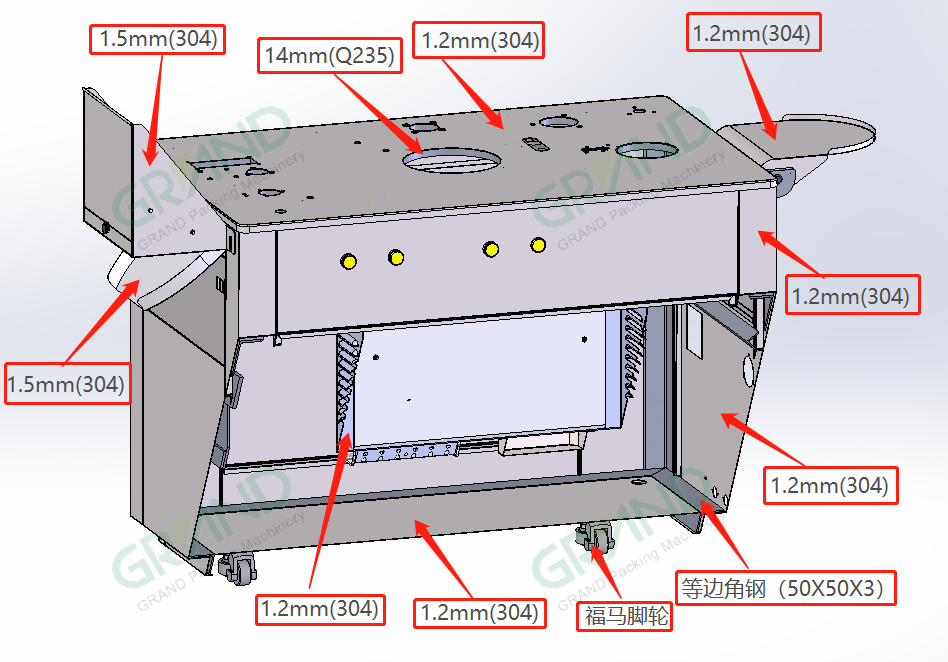

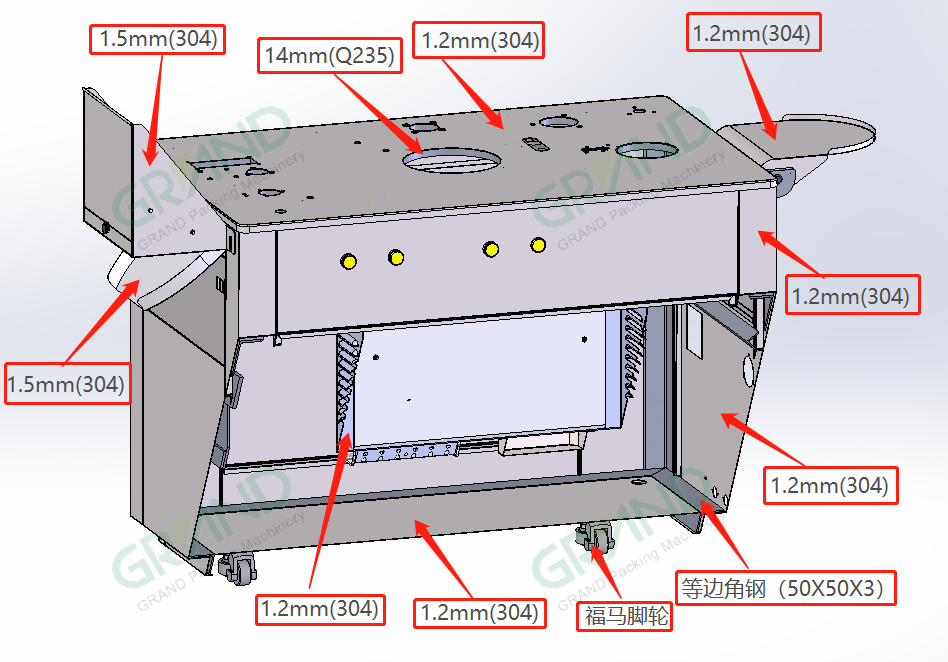

New machine body material

| Old machine body material

|

Machine body and working platform are made of SUS304 for anti-corrosionand anti-oxidation. | The frame is painted iron plate and covered with stainless steel surface. |

New power connection

| Old power connection

|

The new main power supply aviation plug is upgraded, features exhaust fan of the electrical cabinet. | The old or similar machines have ordinary interfaces or no aviation plug and no exhaust. |

|

|

English

English