Introduction of NJP-600 Full automatic capsule filling machine

This model is an intermittent motion and hole plate type filling full automatic capsule filling equipment. It adopt optimization design for meeting the characteristics of Chinese medicine and the requirement of GMP, it has the characteristics of compact mechanism, small volume, lower noise, precision filling dosage, multi-function, stably running etc. It can finish the following motion at the same time: capsule feeding, capsule separating, powder filling, capsule rejecting, capsule locking, finished capsule discharge and die hole cleaning etc. It is the most ideal hard capsule filling equipment for pharmaceutical and health food industry.

Product Description

NJP-600C Full Automatic Powder Capsule Filling Machine is designed based on the old models (With open style in dosing station and turret) in Chinese market, and it has been developed to fully enclose stations to ensure their performance. And adopts the advanced technology at home and international similar products, The whole machine appeared as Humanity, Automation, Stability, Beautiful. And in accordance with to CE, ISO and GMP international standard.

Main Features

1.Automatic capsule filler machine has been improved the inner design turret, and imports beeline bearings for each machine from Japan directly, so that it can be sure a longer usage-life and precision of machine.

2.The working station cam runs under the good lubricating condition, and maintains the inner lubrication of cam slot to a full extent, increasing the pressure pulverization oil pump, thus extends the operation life of the spare parts.

3.It is controlled by the computer, has a stepless timing with the frequency-conversion, the numeral showing makes an easy operation and clear appearance.

4.The multi-bore dosing brings a precision dosage (it is controlled around ±3.5%); The capsule qualified rate is higher than 99%..It can be filled with the Chinese traditional medicine and the Western medicine.

5.It has a protector equipment for the operator and the machine and an automatic pause equipment when it is lack for the material. It has a steady and safe working, it is the best choice for the hard capsule made factories.

Main technical parameter

Equipment Model | NJP-600C |

Machine weight | 800kg |

Overall dimension | 810 ×945× (1930+150) mm |

Motor power | 1.87kw + 2.2kw (Dust Collector) |

Power supply | 3 phase, AC 380V, 50Hz |

Max. Output | 36000capsules/h |

Capsule size | 00#~5# and safety capsule A~E |

Capsule using rate | ≥ 99.5% |

Noise index | ≤ 75dBA |

Dosage difference | ≤ ±3% (under more than 300mg dosing and 40~80 mesh after g ranulation) |

Water supply | Water cycle pump compound water tank, or meet water source |

Vacuum degree | -0.02~-0.06 MPa |

Water volume | 250L/hour |

Enter pipe inner-diameter | 20mm |

Waterspout inner-diameter | 27mm |

Working temperature | 21℃ ± 3℃ |

Working relative humidity | 40~55% |

Exhaust capacity | 210m3/h |

Special function | Granule and powder mixed filing; Powder collector |

Control system | Stepless frequency conversion control, PLC control, with touch screen |

Material | Spare part contact with medicine adopt superior S.S 304 & GMP compliable material |

Criterion | Comply to GMP completely |

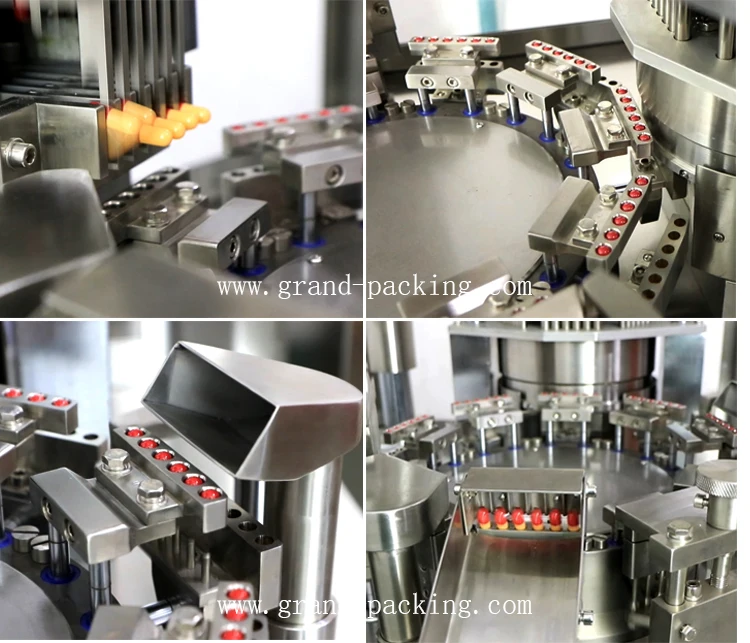

Sample Display

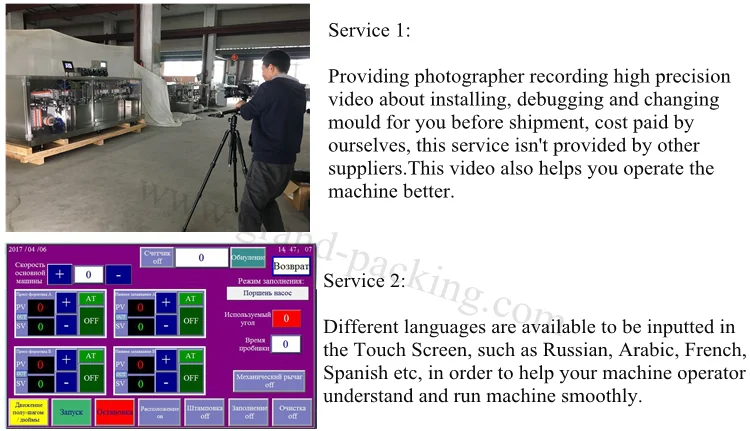

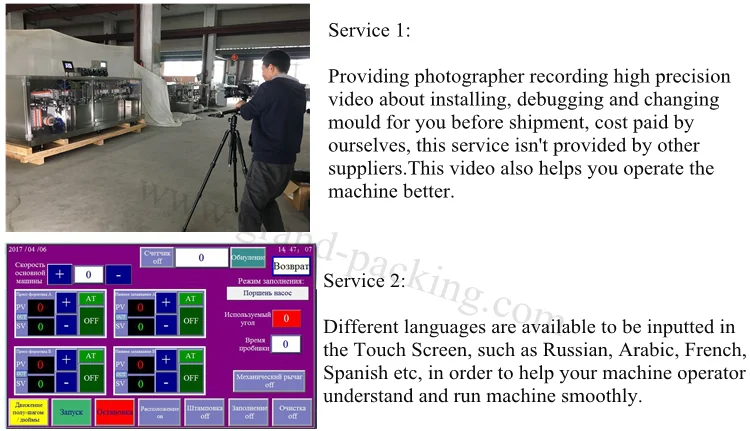

Our Services

Service 3: We will dispatch engineers to your site for machine installation and commissioning, and also do the training for your technicians.

Service 4: We makes guarantee of the machine for 12 (twelve) months. During this Warranty period, the seller will provide free spare parts that cause by the machine’s quality within 10 days by fast courier upon receipt of buyer’s notice.(we will also provide one set of spare parts /wear &tear parts to customer along with the shipment of the machine.

Service 5: We warmly welcome the suggestions from customer to make us grow better and produce better machine along with providing better service to customer, and create more value for customer.

Service 6: Before placing the order or before shipping, welcome to our factory to take a visit to inspect our machine. we will pick you up in the airport or train station and arrange your following schedule in our city to bring you a nice journey during this visit.

ABOUT US

Packaging & Shipping

English

English