Features of Product:

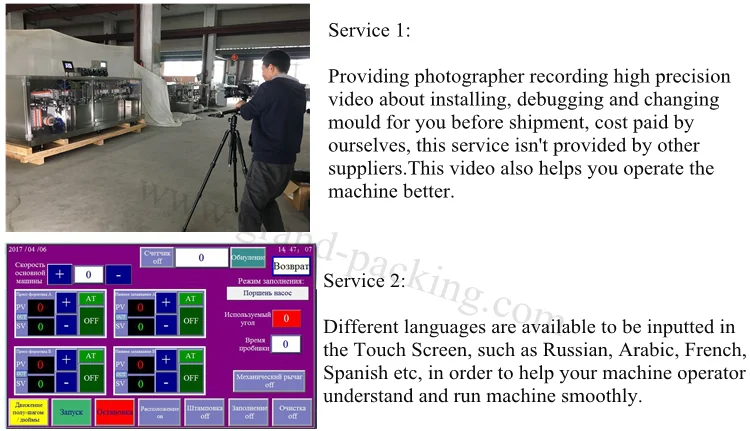

1. It is of touch screen control, multi-system integrated and its degree of automation is higher;

2. Conventional feeding and vacuum feeding are optional in accordance with applicable scene;

3. Material-lacking overload is under automatic protection which can ensure materials’ smooth supply;

4. Capsule’s baiting, orientation and in-place are accurate and speed can be controlled;

5. Sizing treatment is even and secondary sizing treatment technology locks sealing effect;

6. It adopts highly-sensitive temperature sensor, by which, temperature of glue box can be real-time controlled;

7. Glue box adopts asbestos heat insulation for design, by which, operations are safe and reliable;

8. It adopts precision pneumatic control system which ensures glue box’s working smoothly up and down and forward and backward;

9. Glue box and machine body adopt separating and closing design, by which, it can be easily disassembled and easily cleaned;

10. Its originally created function of capsule chain plate positive and negative conveying can effectively extend conveying distance;

11. It adopts reciprocating conveying mechanism, it can be naturally dried which does not affect drug properties inside capsule;

12. Its part contacted with drug is manufactured fully by stainless steel which conforms to GMP standard.

Working Principle:

After materials of hard capsule are baited from hopper, capsule caps and capsule bodies are neatly aligned on conveying mechanism along the same direction by positioning mechanism, after passing through sizing treatment mechanism, connection place of capsule cap and capsule body is automatically coated with safety spill-proof glue (adopting secondary sizing treatment technology to ensure sizing treatment effect) by sizing treatment wheels, then they are naturally solidified in process of conveying mechanism’s reciprocating conveying and after product is rapidly dried, effect for sealing of hard capsule cap and capsule body will be achieved.

Technical Parameters

Range of Application | 0#、1#、2#、3# |

Production Efficiency | ≤ 40, 000 pcs/Hour (Water-soluble Sealing Materials) ≤ 50, 000 pcs/Hour (Non-water-soluble Sealing Materials) |

Rated Power | 2W |

Power Supply | 220/50HZ(can be customized) |

Temperature of Water-soluble Glue Solution | 30℃-40℃ |

Environmental Requirements | Around 25℃ and Humidity of 45%-75%

|

Weight | 1000KG |

External Dimensions

| 2000×700×1650mm |

Sample Display

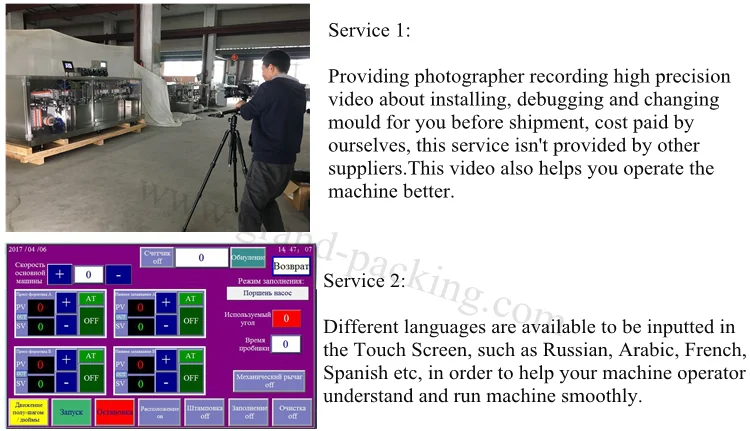

Our Services

Service 3: We will dispatch engineers to your site for machine installation and commissioning, and also do the training for your technicians.

Service 4: We makes guarantee of the machine for 12 (twelve) months. During this Warranty period, the seller will provide free spare parts that cause by the machine’s quality within 10 days by fast courier upon receipt of buyer’s notice.(we will also provide one set of spare parts /wear &tear parts to customer along with the shipment of the machine.

Service 5: We warmly welcome the suggestions from customer to make us grow better and produce better machine along with providing better service to customer, and create more value for customer.

Service 6: Before placing the order or before shipping, welcome to our factory to take a visit to inspect our machine. we will pick you up in the airport or train station and arrange your following schedule in our city to bring you a nice journey during this visit.

Company Information

ABOUT US

Hunan Grand Packing Machinery Co.,Ltd is specialized in the pharmaceutical and packing machinery for more than 10 years, such as plastic ampoule forming filling and sealing machine, capsule filling machine, blister packing machine, strip packaging machine, cartoning machine etc. We have provided services and machines to many different countries and regions in the whole world, such as Indonesia, Thailand, Malaysia, Philippines, New Zealand, Korea,the Middle East area, Poland, Belgium, France, UK, Greece, Italy, Turkey, USA, central and south America such as Trinidad and Tobago,Mexico, Brazil, Russia, Ukraine, UZ, Tunisia, Algeria, Morroco etc. And we always gain the good reputation from customer both from the machine quality and after sales service.

customer visit at our factory and our visit to customer

Our factory

We are cooperating with various kinds of factories and companies in different fields, including pharmaceutical factory, food factory, supplement factory, agrochemical factory such as for pesticide, fertilizer, personal care product factory, such as for cosmetic product, daily use product, stationery factory, hardware factory etc.

English

English