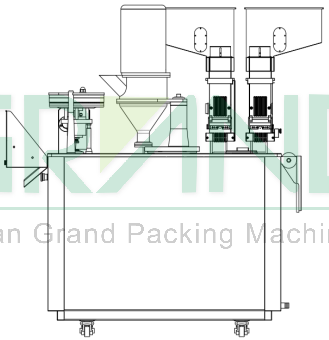

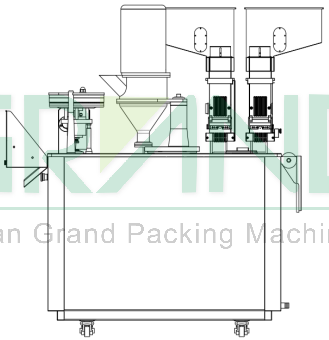

New Type Semi Automatic Capsule Filling Machine

(Double head capsule filling machine)

Model: CGN208-H

Machine Details

Double Capsule feeding station

Capsule delivery structure

|

| Capsule closing station |

Button control (vertical closing)

Touch screen and PLC control (horizontal closing)

Filling hopper cylinder

Electrical cabinet

|

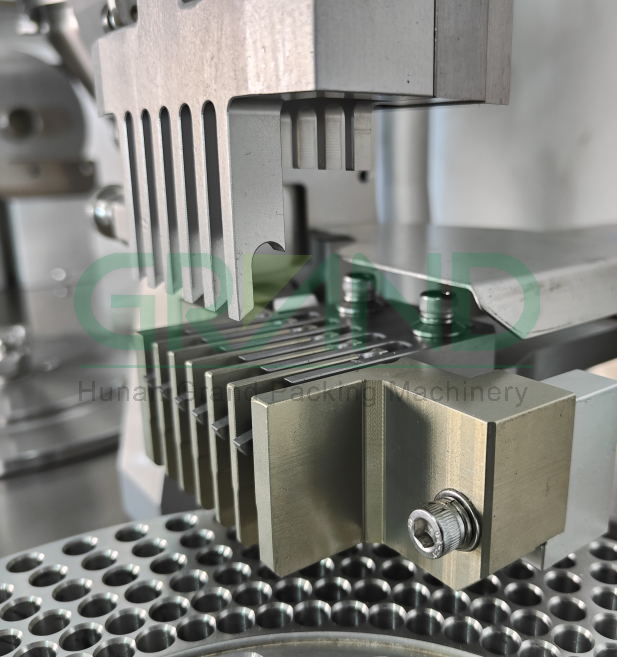

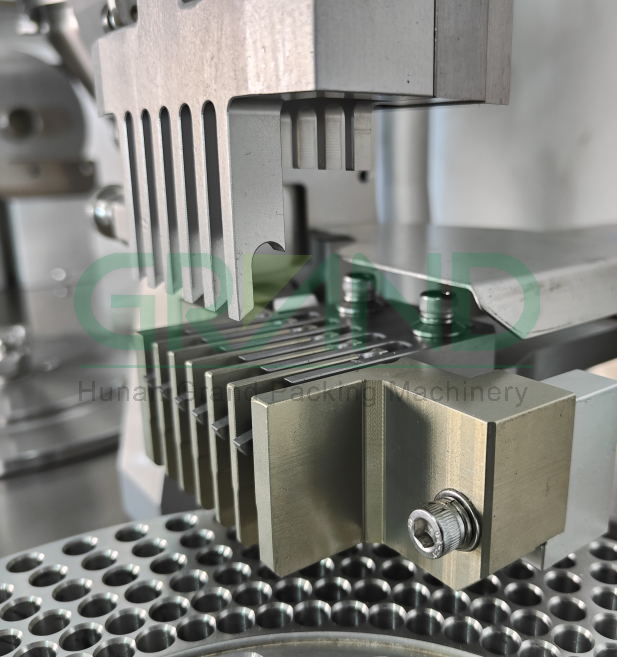

| Powder pressing plate |

Introduction

(1) The double-head semi-automatic capsule filling machine is our upgraded performance-enhancing machine to solve the insufficient production capacity of the existing semi-automatic capsule filling machine.

(2) The whole machine adopts programmable control system, touch screen for operation, stepless frequency conversion for debugging, and pneumatic control.

(3) The machine adopts double-head capsule inserting mechanism, the inserting speed is twice as fast as that of the single-head machine.

(4) The linear track for capsule holding switch is more convenient and accurate to adjust the opening position of the capsule holding bracket. (Patented)

(5) The double-head capsule inserting mechanism adopts independent support structure, improving the accurate positioning of the capsule inserting for higher capsule filling percentage. (Patented)

(6) The front plate of the small capsule hopper can be opened for convenient cleaning. (Patented)

(7) The large and small capsule hoppers features fast positioning, and can be quickly disassembled and assembled without special tools. (Patented)

(8) The capsule inserting ring adopts linkage operation to avoid the drawbacks of continuous acceleration and deceleration, and can achieve high speed operation. (Patented)

(9) The capsule inserting ring holder adopts a easy-pack structure, which can be more easily unpacked and stored. (Patented)

(10) The whole filling station is supported by a short lever under the station, making the filling process more stable and accurate.

(11) The new safety horizontal capsule locking device overcomes the disadvantages of the exposed cylinder and air pipeline of the old model, which is more safe and reliable. (Patented)

(12) Powder sieving for finished capsule discharging mechanism can be overall disassembled and installed in half a minute, convenient for thorough cleaning without dead ends. (Patented)

(13) The capsule ring self-rotation design for easy and smooth separation of capsules.

(14) The machine frame and worktable are made of stainless steel, which is anti-corrosion and oxidation.

Main Technical Parameters of CGN208-H Semi-automatic Capsule Filing Machine

No. | Item | Description |

1 | Production capacity | 25000-40000pcs/hour (depending on the capsule size) |

2 | Suitable capsule size | 00L, 00#, 0L#, 0#, 1#, 2#, 3#, 4# |

3 | Filling material | Pellet, powder without moisture, granules |

4 | Total power consumption | 4.0kw |

5 | Compressed air | 0.03m3/min, 0.7Mpa |

6 | Vacuum pump | Pumping rate 63m3/h |

7 | Machine dimension | 1.79×0.7×1.7 m (L*W*H) |

8 | Overall package dimension | 1.95×0.85×1.75 m (L*W*H) |

9 | Air cargo package dimension | 1.65×0.8×1.45 m (L*W*H) |

10 | Net weight | 500 kg |

11 | Gross weight | 550kg |

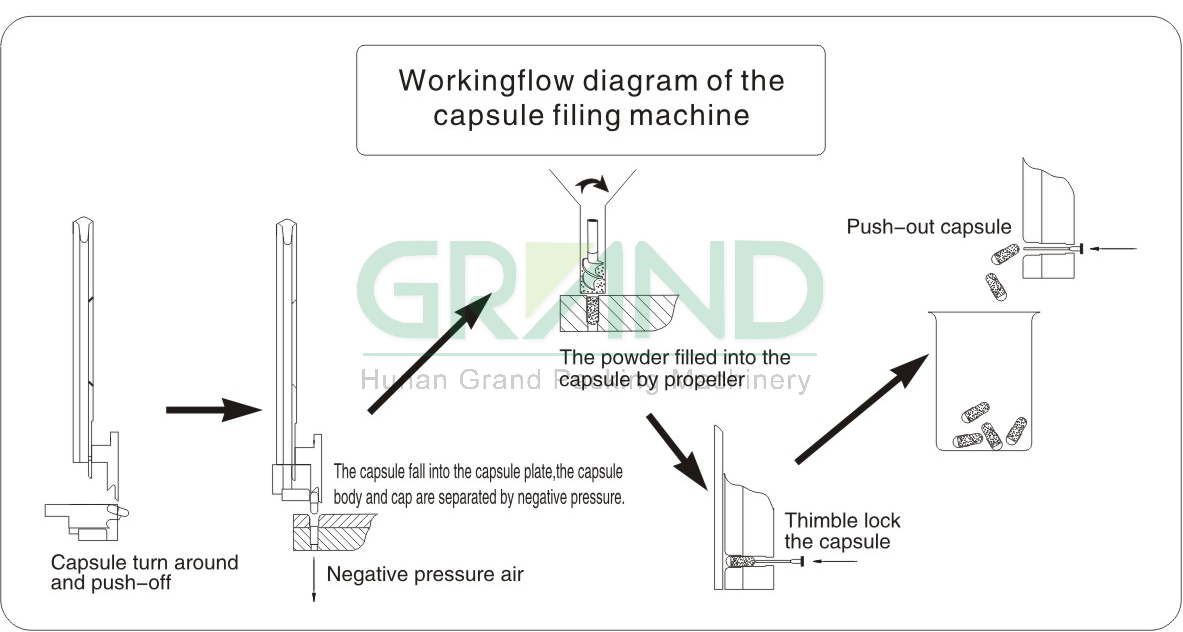

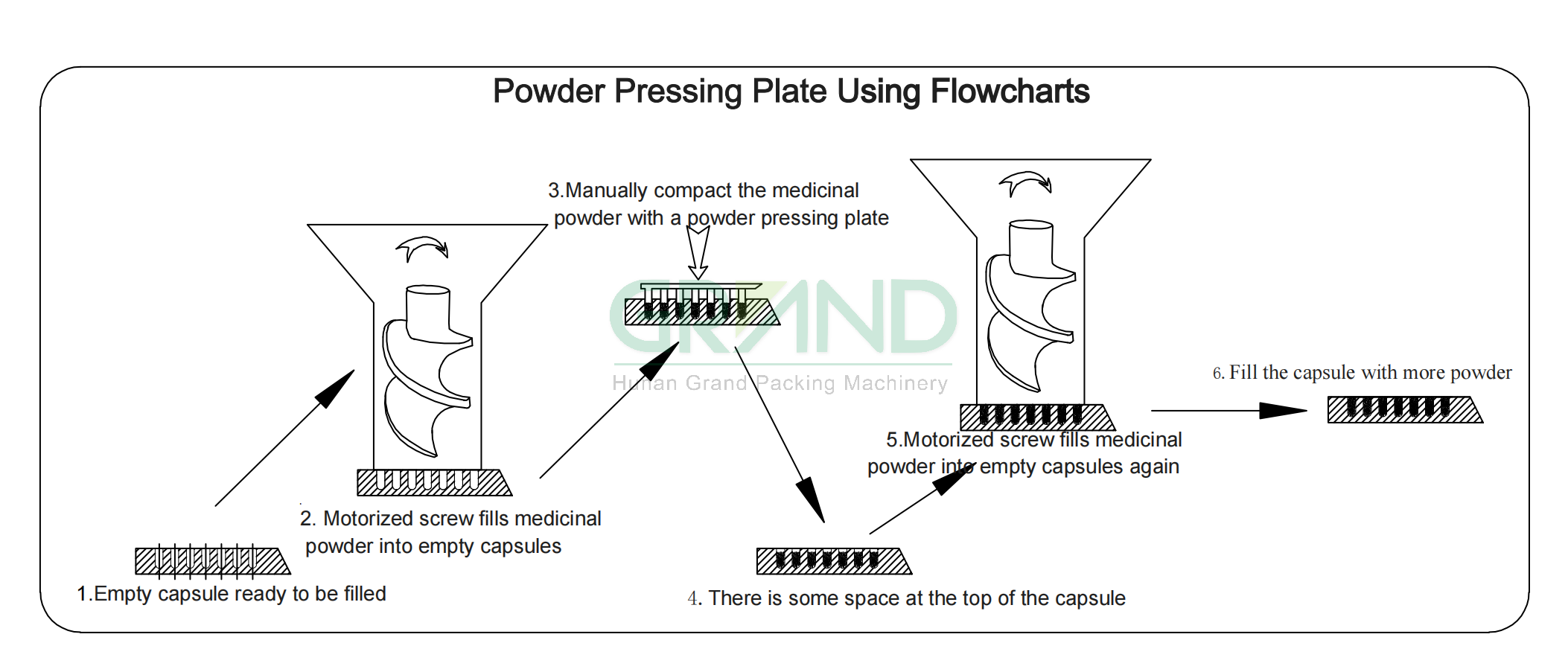

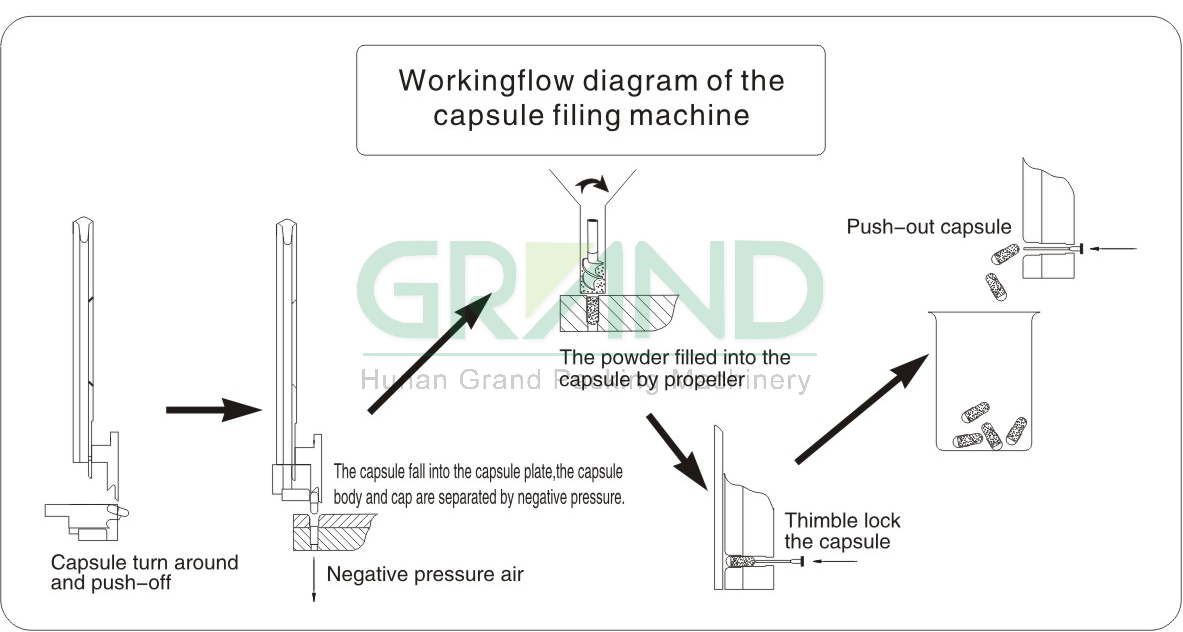

Working diagram

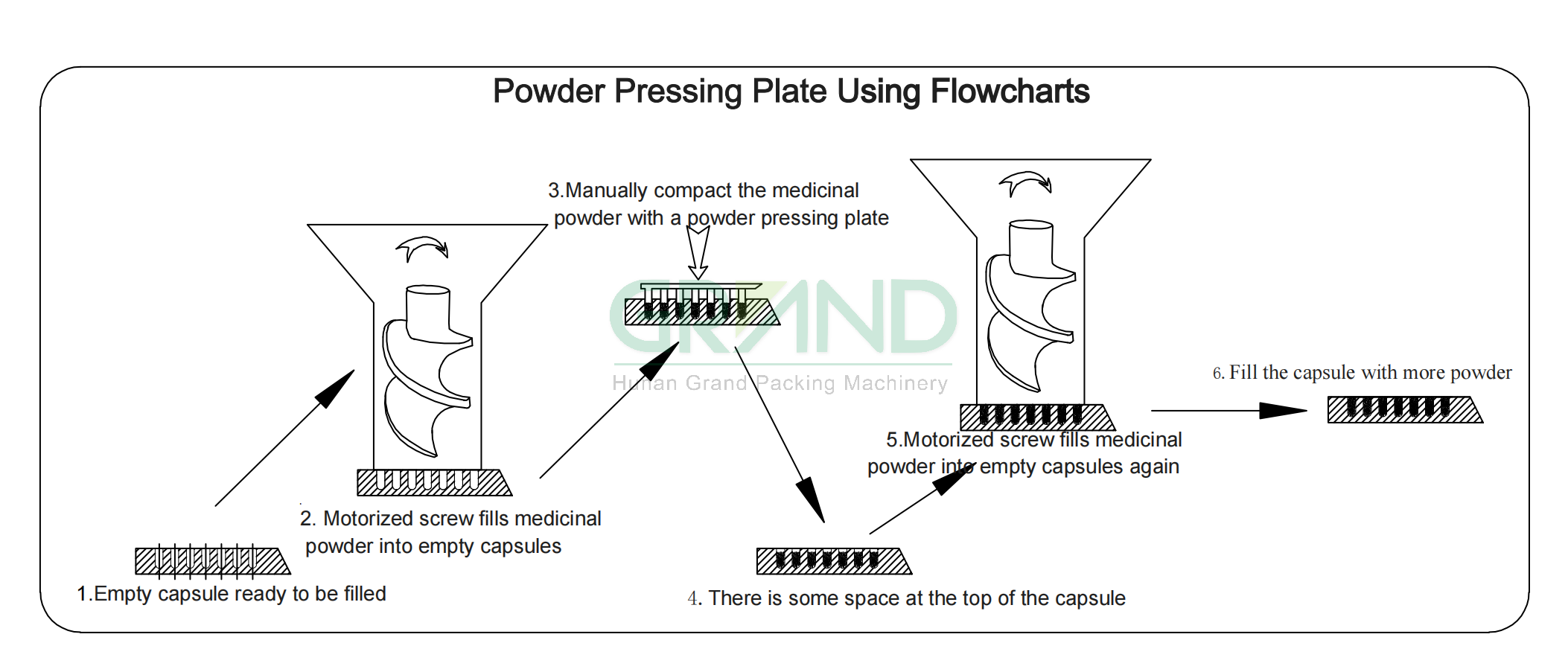

The function of the Powder pressing plate

If you want to fill more powder into the capsule, then we can use the pressing plate to press on the filled powder and fill for the second time.

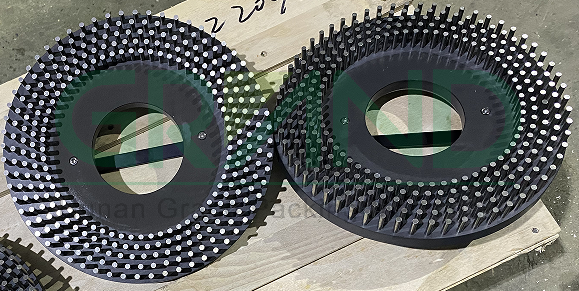

Packing List of CGN208-H moulds

No | Items | Qty | Weight | Material |

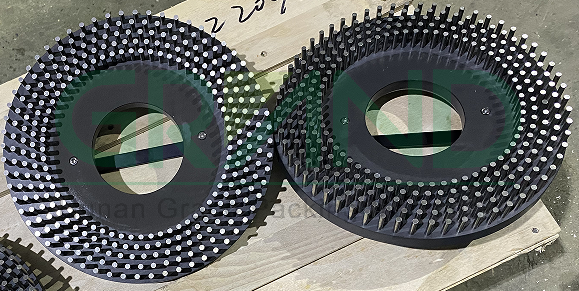

1 | Capsule ring | 2 sets | 5.4kg | LY12 aviation alloy |

2 | Pin disc | 1 pc | 3.8kg | LY12 aviation alloy 304 Stainless steel |

3 | Capsule feeding plate | 2pcs | 1.9kg | LY12 aviation alloy 304 Stainless steel |

4 | Capsule sorting plate | 2pcs | 0.9kg | LY12 aviation alloy |

5 | Capsule feeding fork | 2pcs | 0.4kg | LY12 aviation alloy |

6 | Regulating bar | 1 set | 0.2kg | 304 Stainless steel |

7 | Packing box | 1 | 2.2kg | Fumigation free wood |

Single capsule ring packing size and weight 310X310X90mm,4KG | A full set of mould with package at 16kg |

English

English