Machine Application

The automatic coffee capsule packaging machine is suitable for packing all kinds of coffee, such as Keurig K-CUP, Nespresso, Dolce Gusto, Lavazza, etc. With the highest level of quality, the machine has achieved the highest speed of 50 times per minute in China now. Combined world advanced technology with our company’s upgrade technology, the machine has got multiple patents. It is well-welcomed by customers at home and abroad.

Feature

1.It adopts the leakproof type servo screw for high precision of filling, and the highest precision can be 0.05 g in the stable test, which is the most advanced level all over the world. All parts contacting with products is made of SS304. (Patented design, counterfeiting is not allowed!)

2.The completely powder sucking device developed by our company can achieve nearly 100% no dust on rim. (Patented design, counterfeiting is not allowed!)

3.The mould plate and mould hole cleaning device adopt the wear resistant brush, which is driven by the motor to rotate for cleaning them. That can ensure the cleanliness of the whole mould plate and mould hole, as a result, there is no residual dust on the packed finished product.

4.The whole machine adopts the meter box driven by the imported motor to drive the mould chain plate to run. The storage cup conveyor belt is driven by the mechanical connecting rod device at the same time, the cup is taken by the mechanical arm, the dust on the cup rim is cleaned by vacuum, and the finished product is pushed to the conveyor belt. The synchronous drive is achieved through a motor, and the machine can achieve synchronous operation. Not only does it have high speed, but also it will have a longer service life.

5.The machine adopts the integrated mechanism of the sealing and cutting device which are controlled by the servo system. Such unique design where the two devices are contained inside the machine frame saves a lot of room for customers.

6.The whole machine is equipped with detection devices. If there is no cup, it won’t fill; and if there is no film, it won’t seal.

7.The independent control sealing device developed by our company can guarantee a tight and elegant seal. Meanwhile, if there is one place goes wrong, other parts of the machine can continue to run normally.

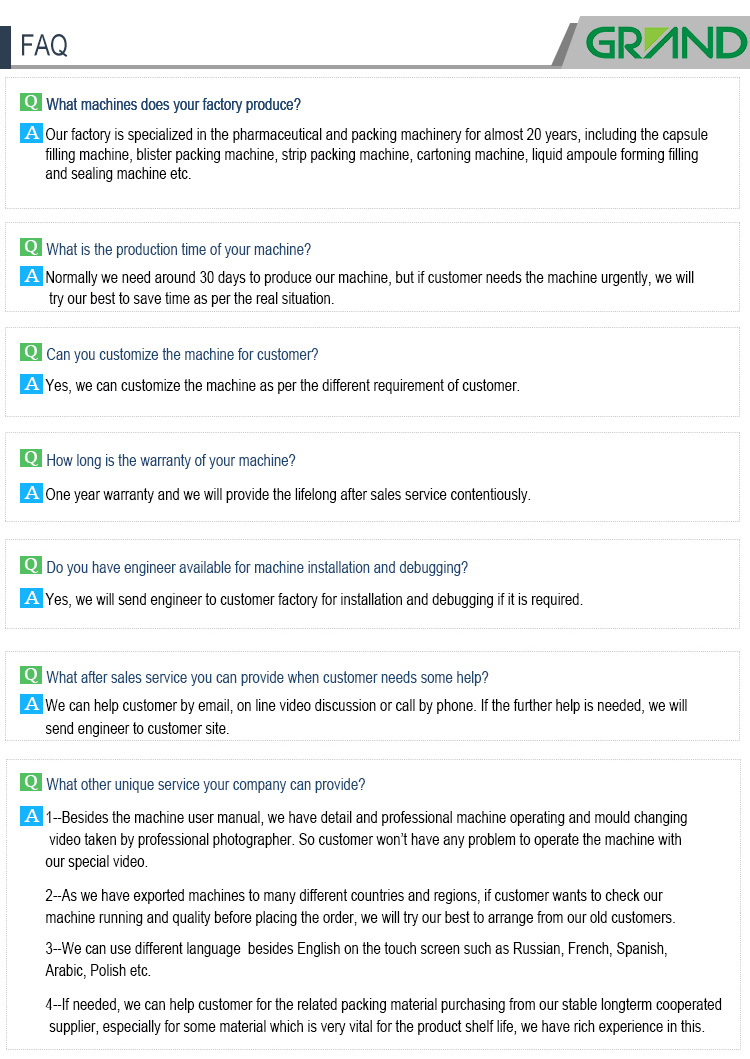

Machine Technical Parameter

| Model | TM-F400L |

| Material | Ground coffee |

| Production capacity | (40-55)*4 pieces/min |

| Filling method | Servo drive screw for filling |

| Filling Weight | 0-20g |

| Filling Accuracy | ±0.05g |

| Power supply | 3 Phase 220/380V 50/60HZ 5kW |

| Air Supply | ≥0.6Mpa |

| Machine weight | 1500Kg |

| Machine dimension | 3600*900*2000 mm |

Sample Display

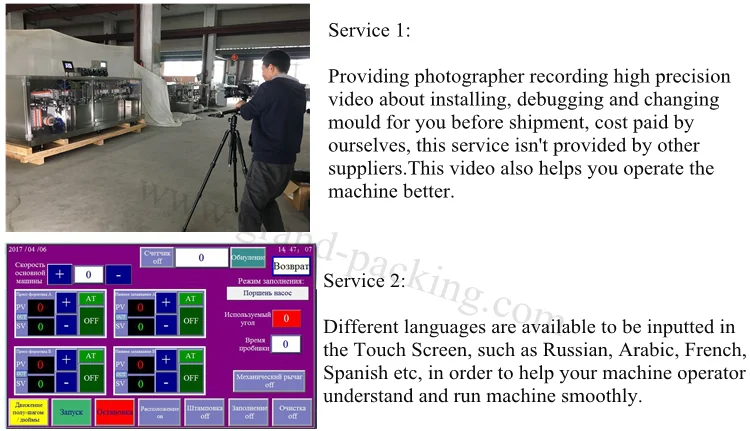

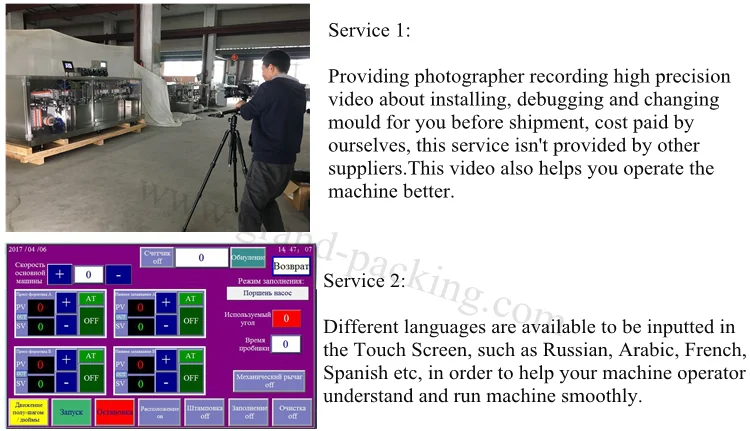

Our Services

Service 3: We will dispatch engineers to your site for machine installation and commissioning, and also do the training for your technicians.

Service 4: We makes guarantee of the machine for 12 (twelve) months. During this Warranty period, the seller will provide free spare parts that cause by the machine’s quality within 10 days by fast courier upon receipt of buyer’s notice.(we will also provide one set of spare parts /wear &tear parts to customer along with the shippment of the machine.

Service 5: We warmly welcome the suggestions from customer to make us grow better and produce better machine along with providing better service to customer, and creat more value for customer.

Service 6: Before placing the order or before shipping, welcome to our factory to take a visit to inspect our machine. we will pick you up in the airport or train station and arrange your following schedule in our city to bring you a nice journey during this visit.

Company Information

ABOUT US

Hunan Grand Packing Machinery Co.,Ltd is specialized in the pharmaceutical and packing machiney for more than 10 years, such as plastic ampoule forming filling and sealing machine, capsule filling machine, blister packing machine, strip packaging machine, cartoning machine etc. We have provided services and machines to many different countries and regions in the whole world, such as Indonesia, Thailand, Malaysia, Philippines, New Zealand, Korea,the Middle East area, Poland, Belgium, France, UK, Greece, Italy, Turkey, USA, central and south America such as Trinidad and Tobago,Mexico, Brazil, Russia, Ukraine, UZ, Tunisia, Algeria, Morroco etc. And we always gain the good reputation from customer both from the machine quality and after sales service.

customer visit at our factory and our visit to customer

Our factory

We are cooperating with various kinds of factories and companies in different fields, including pharmaceutical factroy, food factroy, supplement factroy, agrochemical factroy such as for pesticide, fertilizer, personal care product factroy, such as for cosmetic product, daily use product, stationery factroy, hardware factroy etc.

English

English