Characteristics:

The maximum production capacity of this machine can reach 260 capsules per minute. Standard and serial production: the interchangeability of manufacturing parts can reach above 99%; each spare part has its own regular code; while changing the mould, all the parts are fixed by the location hole with high precise; it’s very efficient to change the moulds, easy to operate and clean the machine.

Main performance:

1. Improve the driving cams of all stations, from original outer cam pulled by spring to inner groove cam made of high-quality special material. This change, eliminating the disadvantages of easy fatigue and short service life for spring pulling method, makes the machine more wearable and stable.

2. In consideration of the medicine dust easy to enter the machine mould after long-time running, causing the mould rotary plate to be disassembled for cleaning, the innovation design of seal ring preventing dust from outside is developed and applied to this machine, which completely ensures the sealing in running process and eliminates the shortcoming of tedious maintenance.

3. This machine adds the inching control system, convenient for the human-oriented operation in manufacturing and cleaning process.

4. If lack of capsule, the liquid feeding will stop automatically.

Compared with the other machine models in same industry, our 260 machine has such advantages as below:

1. This liquid capsule filling machine improves the internal design of mould rotary plate and adopts original Japan linear bearing, which can ensure its precision and service life.

2. It employs the cam underneath design and adds the pressure atomization oil pump, which can keep the cam groove lubricant, reduce wear and prolong the service life of accessories.

3. The upper and lower moulds of this machine carry out one-way movement. With employing the imported double-lip PU seal ring, it has very good sealing performance.

4. It adopts computer control, stepless frequency control of motor speed and digital display to make the operation more simple and intuitive.

5. It’s equipped with safety protection device for both operators and machine and auto-stop device for material lacking to make the machine run stably, safely and reliably, which is an ideal equipment for those pharmaceutical factories to produce hard capsules such as medicine or functional food.

6. This machine combines the mould blowing with sucking to ensure no dust in the mould hole and improve the rate of good finished capsules.

Main Technical Parameter of NJP-260 liquid capsule filling machine

| Model | NJP-260 Fully automatic liquid capsule filler |

Weight | 900kg |

Dimensions | 1020×860×1970mm |

Power | 5.75kw |

Power supply | 3phase 4 wires AC 380V;50Hz |

Maxi. Capacity | 260 capsules/m |

Capsule specifications | 00#~5# and Safety Capsule A~E |

Capsule feeding rate | ≥99.5% |

noise | ≤75dBA |

Filling precision | Liquid Above 300mg≤±3% |

Compressed air | 0.06m3/min 0.3Mpa |

Water | Recycling water |

Vacuum degree | -0.02~-0.06 MPa |

Water flow | 250L/h |

Intake water diameter | 20mm |

Discharge water diameter | 27mm |

Work environmental temperature | 21℃±3℃ |

Workshop’s height | Manual Feeding≥2.6m, Automatic Feeding≥2.8m |

Related Humidity | 40~55% |

Control system | PLC |

Material | Stainless steel 304 and 316. |

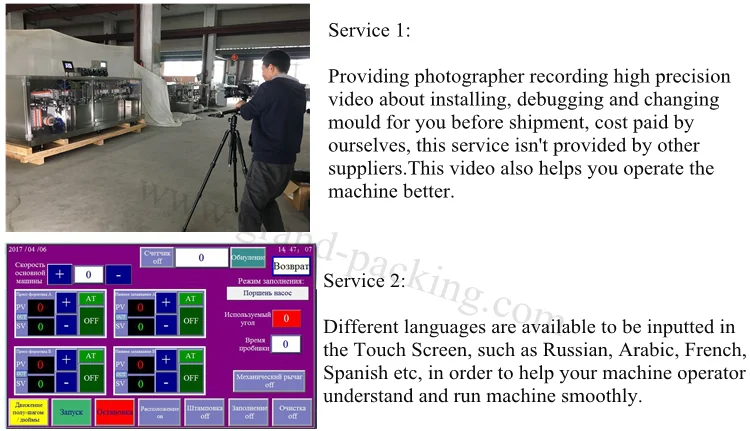

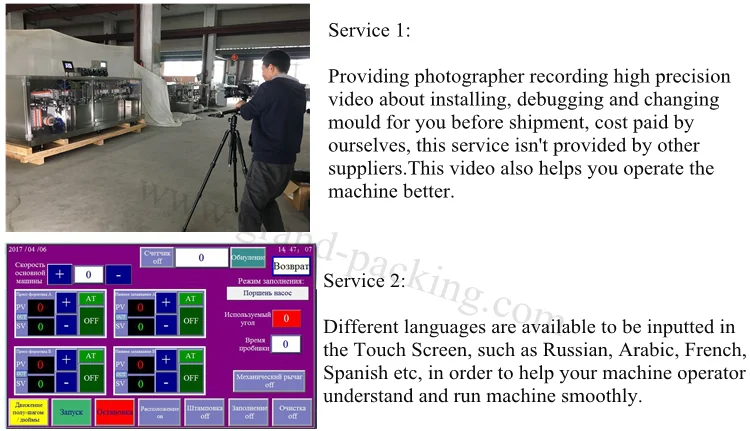

Our Services

Service 3: We will dispatch engineers to your site for machine installation and commissioning, and also do the training for your technicians.

Service 4: We makes guarantee of the machine for 12 (twelve) months. During this Warranty period, the seller will provide free spare parts that cause by the machine’s quality within 10 days by fast courier upon receipt of buyer’s notice.(we will also provide one set of spare parts /wear &tear parts to customer along with the shipment of the machine.

Service 5: We warmly welcome the suggestions from customer to make us grow better and produce better machine along with providing better service to customer, and create more value for customer.

Service 6: Before placing the order or before shipping, welcome to our factory to take a visit to inspect our machine. we will pick you up in the airport or train station and arrange your following schedule in our city to bring you a nice journey during this visit.

Company Information

ABOUT US

Hunan Grand Packing Machinery Co.,Ltd is specialized in the pharmaceutical and packing machiney for more than 10 years, such as plastic ampoule forming filling and sealing machine, capsule filling machine, blister packing machine, strip packaging machine, cartoning machine etc. We have provided services and machines to many different countries and regions in the whole world, such as Indonesia, Thailand, Malaysia, Philippines, New Zealand, Korea,the Middle East area, Poland, Belgium, France, UK, Greece, Italy, Turkey, USA, central and south America such as Trinidad and Tobago,Mexico, Brazil, Russia, Ukraine, UZ, Tunisia, Algeria, Morroco etc. And we always gain the good reputation from customer both from the machine quality and after sales service.

customer visit at our factory and our visit to customer

Our factory

We are cooperating with various kinds of factories and companies in different fields, including pharmaceutical factory, food factory, supplement factory, agrochemical factory such as for pesticide, fertilizer, personal care product factory, such as for cosmetic product, daily use product, stationery factory, hardware factory etc.

English

English