1. Introduction

MGJJ tobacco flavor beads dropping machine is composed of flavor liquid feeding, gelatin feeding, pulse cutting, coolant circulation, cooling system, etc.

The filling materials of MGJJ model ball forming machine are oily materials that are insoluble in water, such as flavors,smoking cessation formulas,cod liver oil, vitamins A, D, E, K, traditional Chinese medicine, vegetable oils, nutrients, etc.

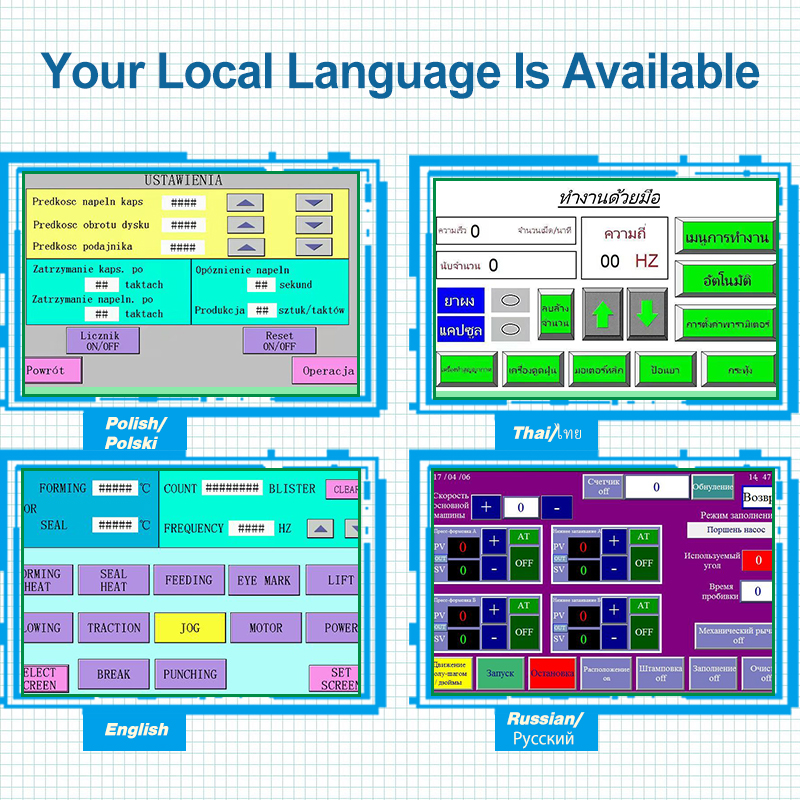

The machine adopts advanced pulse cutting technology, the beads filling is accurate, and capsule forming is well without mold, low cost, easy operation, high degree of automation. The main motor is controlled by PLC control system, 10.1 inch touch screen for parameter display. The machine can be widely used in the mass production of seamless soft capsule in health care products, medicine, food, cosmetics and other industries.

The flavor capsule forming, filling and sealing can be completed instantly with less material consumption and high production yield. Accurate filling volume and good quality of capsules, easy to operate, high degree of automation, compact structure and small area occupation. The entire production line is easy to clean and fully complies with the state GMP related standards.

The parts are in direct contact with the materials are made of 316L stainless steel plate.

2. Sample for Cigarette flavor balls

3. Parameters

| Model | Beads Dia | Volume | Output/Sec | Powder | Volume of gel tank | Core liquid tank volume | Coolant volume | Ambient temperature | Relative humidity | Machine size | Weight |

| MGJJ-S | 2-8mm | 5-150mg | 4-12 pills | 2.2kw 220V | 1.5L | 5L (customized) | 20L | 22-25℃ | 45-60℃ | 800*600*2050mm | 185kg |

| MGJJ-X | 4-16 pills | 2.2kw 380V | 30L | 10L (customized) | 2000*650*2050mm | 230kg |

| MGJJ | 2-10mm | 5-300mg | 2-20 pills | 3.6KW(machine)+4.5KW(60L tank)380V | 60L | 30L | 880*860*1900mm | 280kg |

| MGJJ-II | 2-8mm | 8-48 pills | 50L | 955*855*1900mm | 450kg |

4. Production process

Gelatin melting --> Materials feeding pneumatically --> Cigarette Burst Balls dropping and forming --> Cigarette capsules cooling --> flavor balls conveying --> Cigarette Pills drying --> Menthol Burst Blasting Beads discharge

Here's a more detailed breakdown of the production process:

1. Core Liquid Formation:

A mixture containing flavors, active ingredients, and other necessary substances is prepared.

2. Dripping and Shearing:

This core liquid is then extruded into a falling stream or column.

3. Cooling and Solidification:

A stream of cooling oil is used to shear the liquid column into droplets, which then coalesce and solidify into spherical shapes due to the surface tension of the liquid.

4. Post-Processing:

The resulting beads undergo degreasing and drying to remove any remaining cooling oil and excess moisture.

5. Quality Control:

The beads are then screened and inspected to ensure they meet size, shape, and quality standards.

5.

Layout diagram

Layout diagram

English

English