1. What is Capsule?

2. Capsule Type

3. What is a Capsule Filling Machine?

4. Capsule Maker Machine's Working Principle

5. Types of Capsule Manufacturing Machine

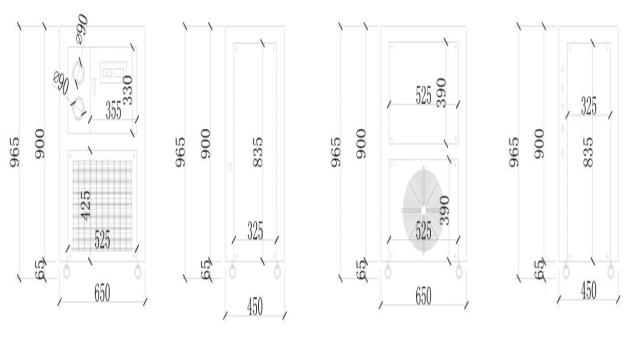

5.2-5.3 .Semi-automatic Capsule Filling Machine

5.4. Automatic capsule filling machine

5.5. Fully Automatic Liquid Capsule Filling Machine

5.6. Liquid capsule banding machine

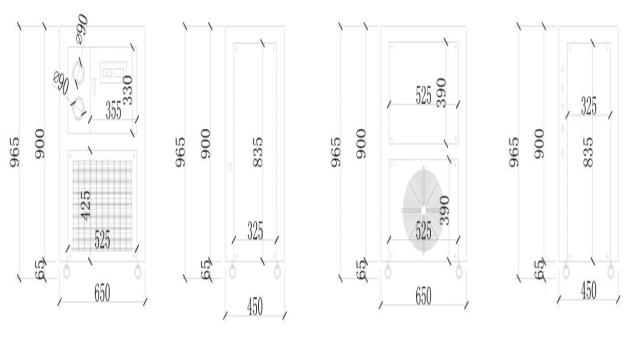

5.7. Softgel Encapsulation machine

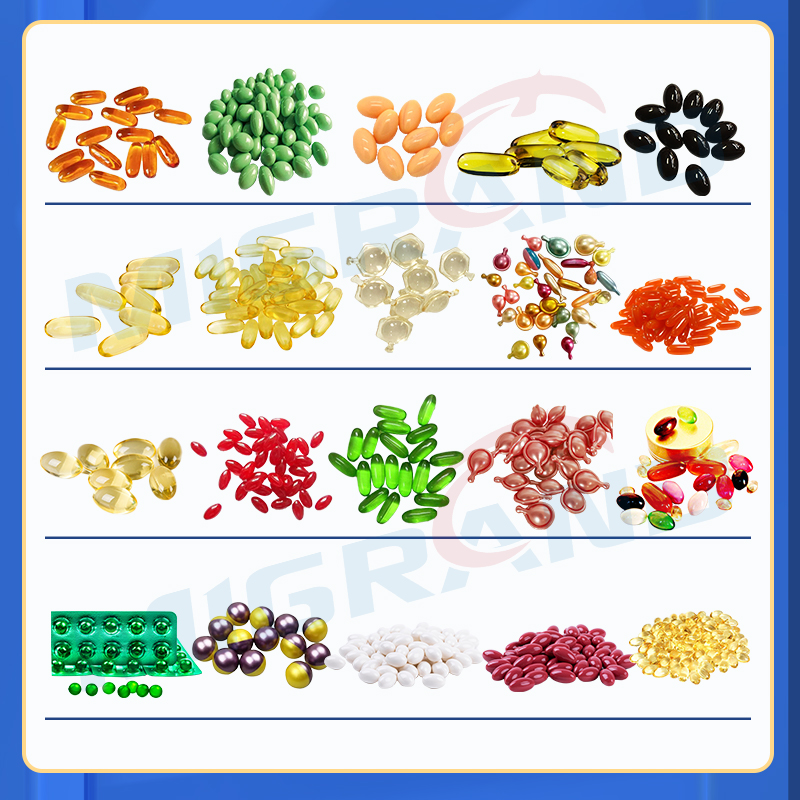

Before understand the softgel making machine, let us know about what soft capsule is.

Softgel refers to a direct sealing of a certain amount of liquid APIs, or the dissolution or dispersion of solid APIs in suitable excipients to prepare solutions, suspensions, emulsions or semi-solids, and seal them in soft capsules.

Soft capsule is becoming more and more popular in the market due to its fast disintegration speed, high bioavailability, elegant appearance, easy to swallow, non-oxidation, easy storage and carrying.

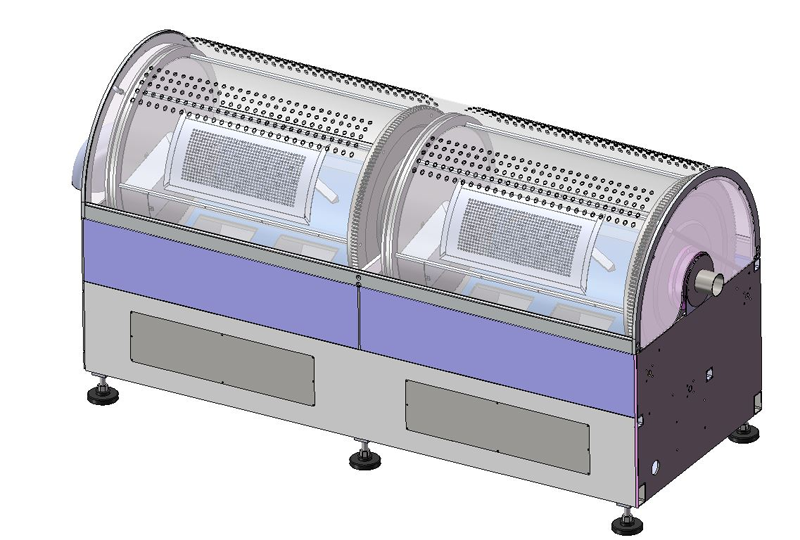

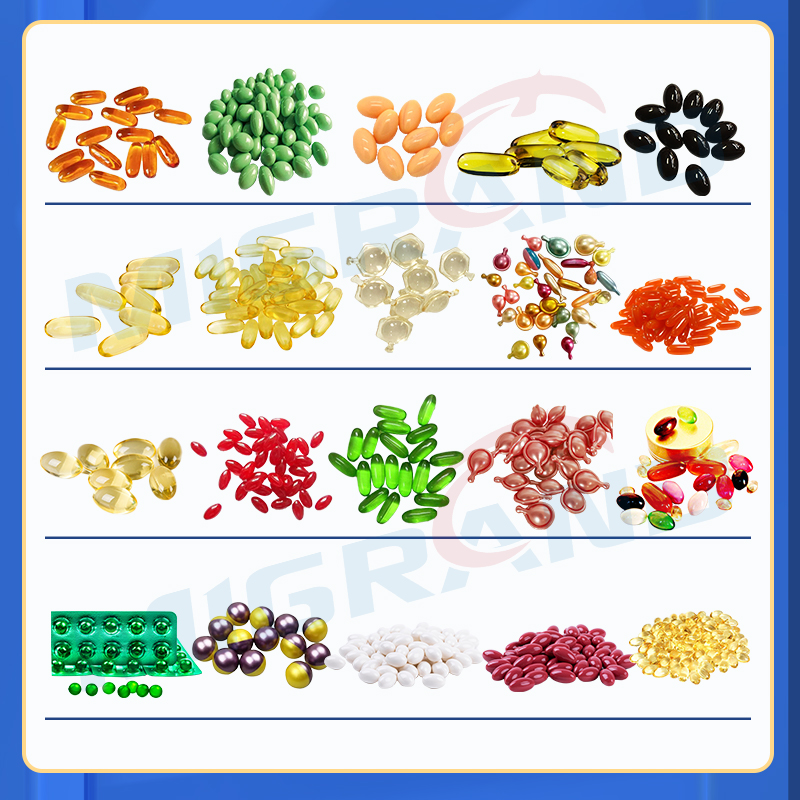

The Soft Gelatin Capsules Filling Machine is a machine that fills a certain amount of oil, suspension, or paste into the gelatin film to form sealed soft capsules of different sizes, shapes, and colors.

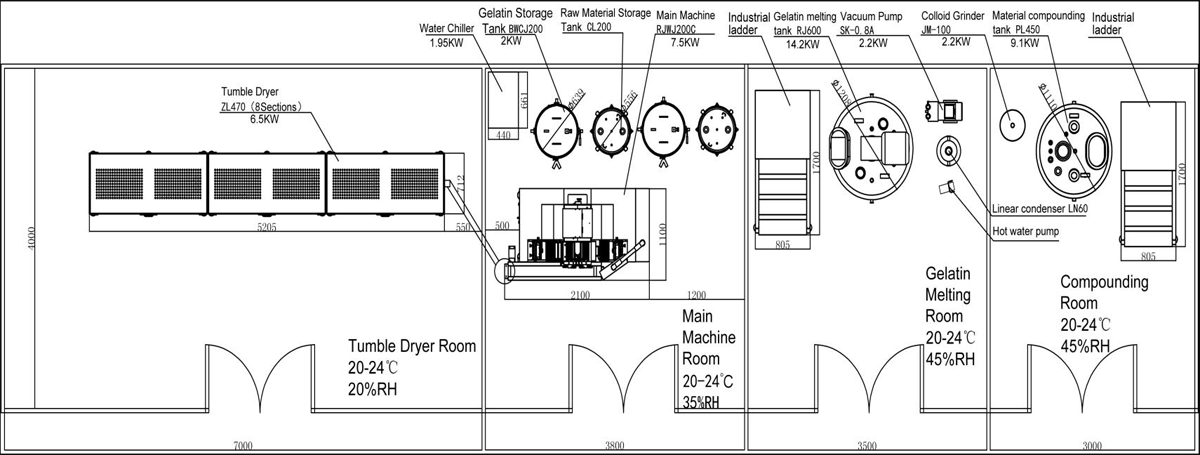

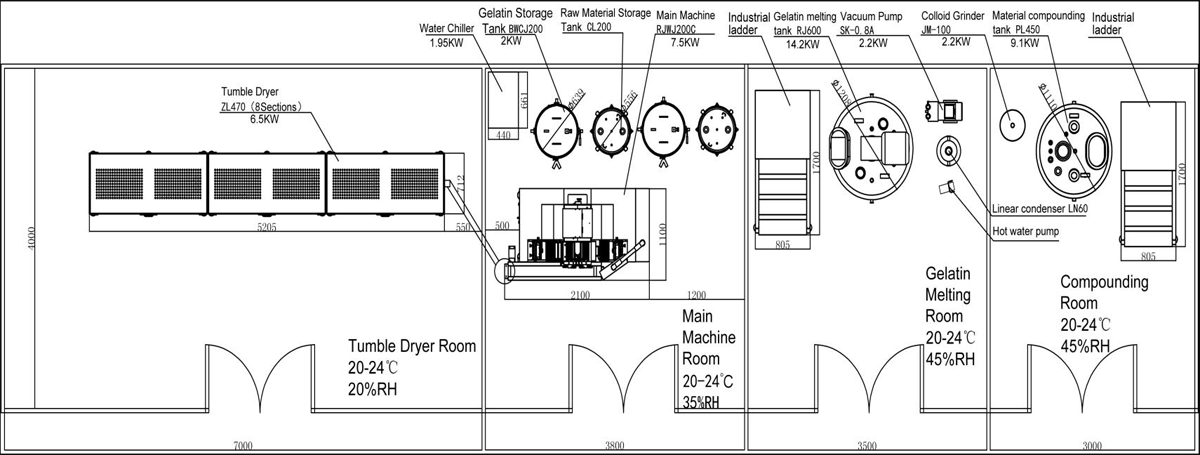

The soft encapsulation is a production line composed of primary machine, mold, conveyor, dryer, air/water cooler, control system cabinet, thermal insulation sol tank, mixing tank, and other related supporting devices.

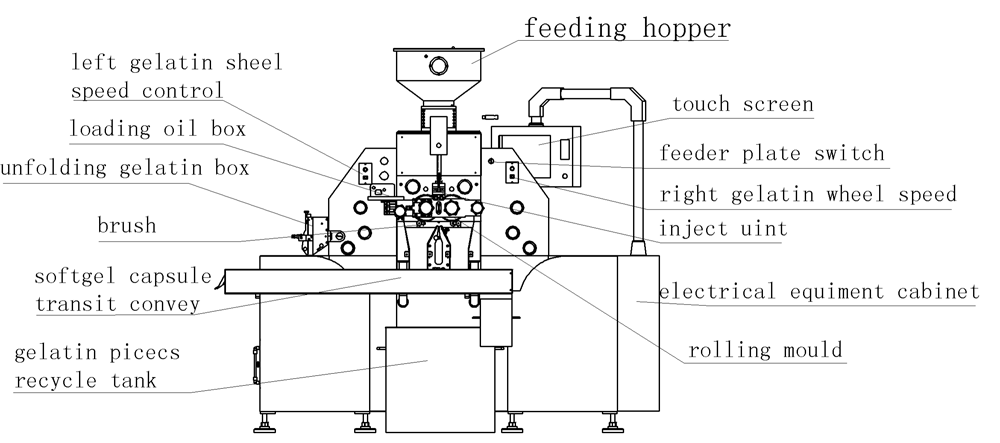

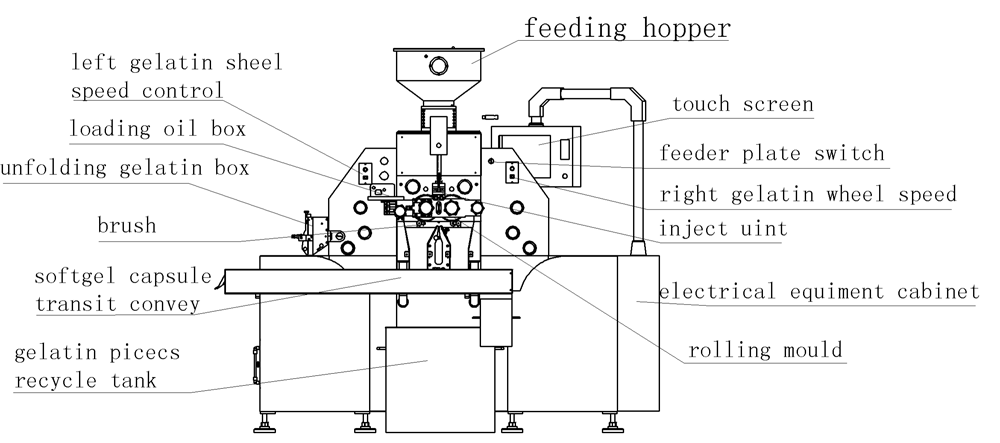

5.7.1. Primary machine

The main machine is the core part of the soft capsule production line, and its function is to complete the preparation of the gel film, the quantitative supply of the contents (in various forms), and encapsulation at the same time. It is mainly including the machine base and body, feeding system, gel wheel, oil roller system, film traction shaft, capsule discharging unit, gel box, lubrication system, etc.

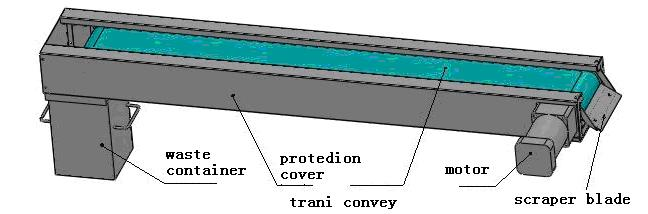

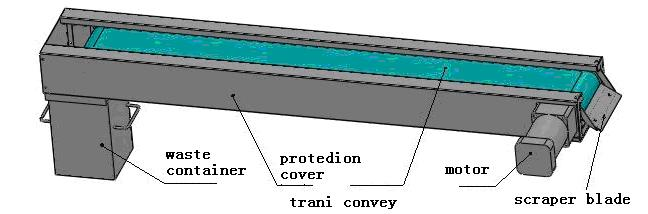

5.7.2. Conveyor

It consists of the conveying unit, motor, chain gear, conveying belt and belt tension adjusting mechanism, used for transmitting soft capsules. By controlling the adjustable switch, the belt is driven to move leftwards to feed the qualified capsules into the tumblers, or to move rightwards to send the rejected capsules into the defective capsule bucket.

5.7.3. Water chilling unit

The unit is used to cool the water inside and then pump it into the pipeline of the system so as to cool the liquid gelatin. Generally, the refrigerating temperature output is controlled at about 16℃~20℃ to ensure qualified strip-shaped gelatin formation.

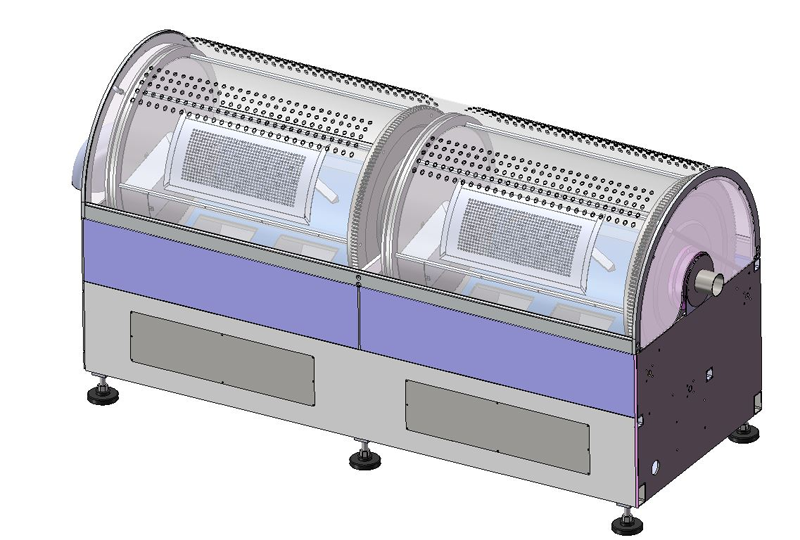

5.7.4. Tumble dryer for formalization

The qualified softgels encapsulated by the primary machine are automatically fed through the conveyor to the inlet of tumble dryer for drying and formalization. The rotary direction of the tumble is controlled by the panel of electric cabinet or touch screen, with the tumblers turning counterclockwise, the capsules are left inside and clockwise, automatically enters a capsule-holding container. The softgel can be discharged at the outlet of the tumble dryer after primary formalization, then the final formalization and drying is carried out after cleaning.

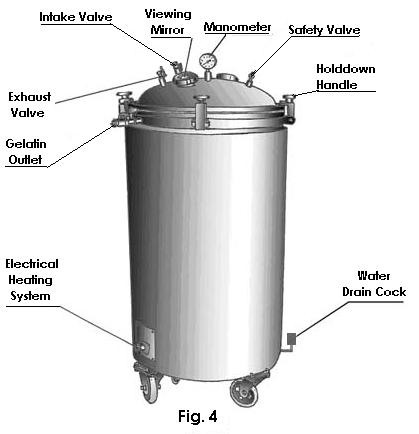

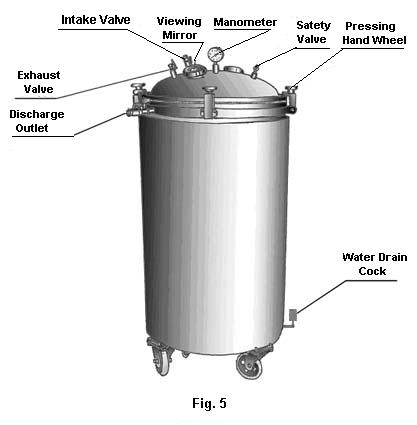

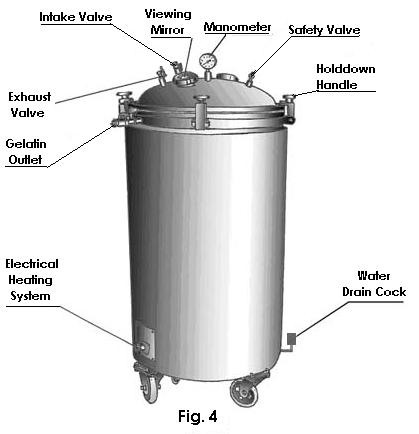

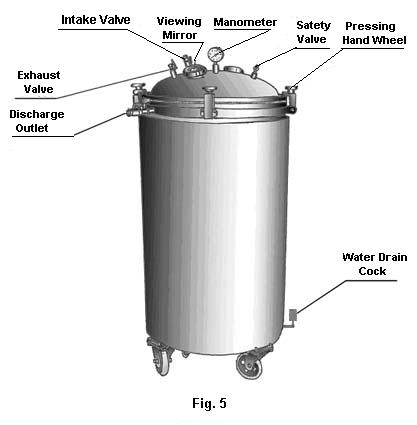

5.7.5. Insulated tank for gelatin storage

The tank is a three-layer container made of stainless steel sheets welded, prepared gelatin liquid is contained in the inner tank with heat preservation stuffs placed between the outer tank and the intermediate. In the sandwich between the inner tank and the intermediate one, soft water is filled, and electric heating pipes and a temperature sensor installed. A temperature controller is provided to indicate and control the water temperature to ensure a desired gelatin liquid temperature. In operation, compressed air is forced into this gelatin storage tank and the gelatin liquid is poured through the liquid-conveying hose into the spreader box by the air pressure (0.04-0.07Mpa).

5.7.6. Electrical control cabinet

The electrical appliances and meters are installed in the cabinet, for controlling and indicating the soft encapsulating machine operating status.

5.7.7. Feed liquid storage tank

The liquid storage tank is formed by welded stainless steel sheets for containing prepared liquid for feeding. During operation, the liquid is forced into the charging hopper by the compressed air, which should be purified atmosphere or nitrogen. An agitator or electrical heating device (both are optional and not supplied with the machine) can be installed on the tank to prevent liquid from delaminating, sedimentating or solidifying.

5.7.8. Working principle

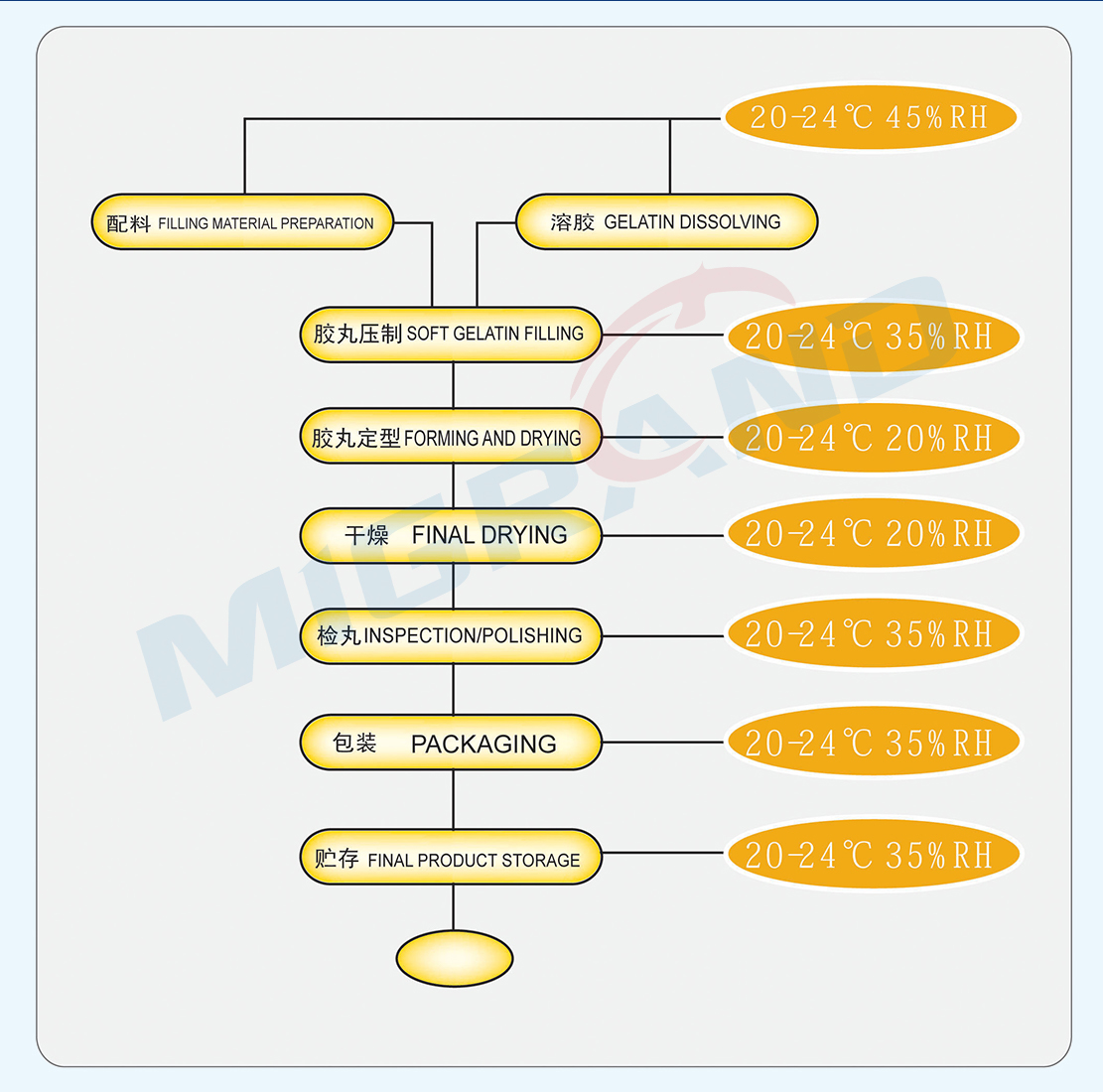

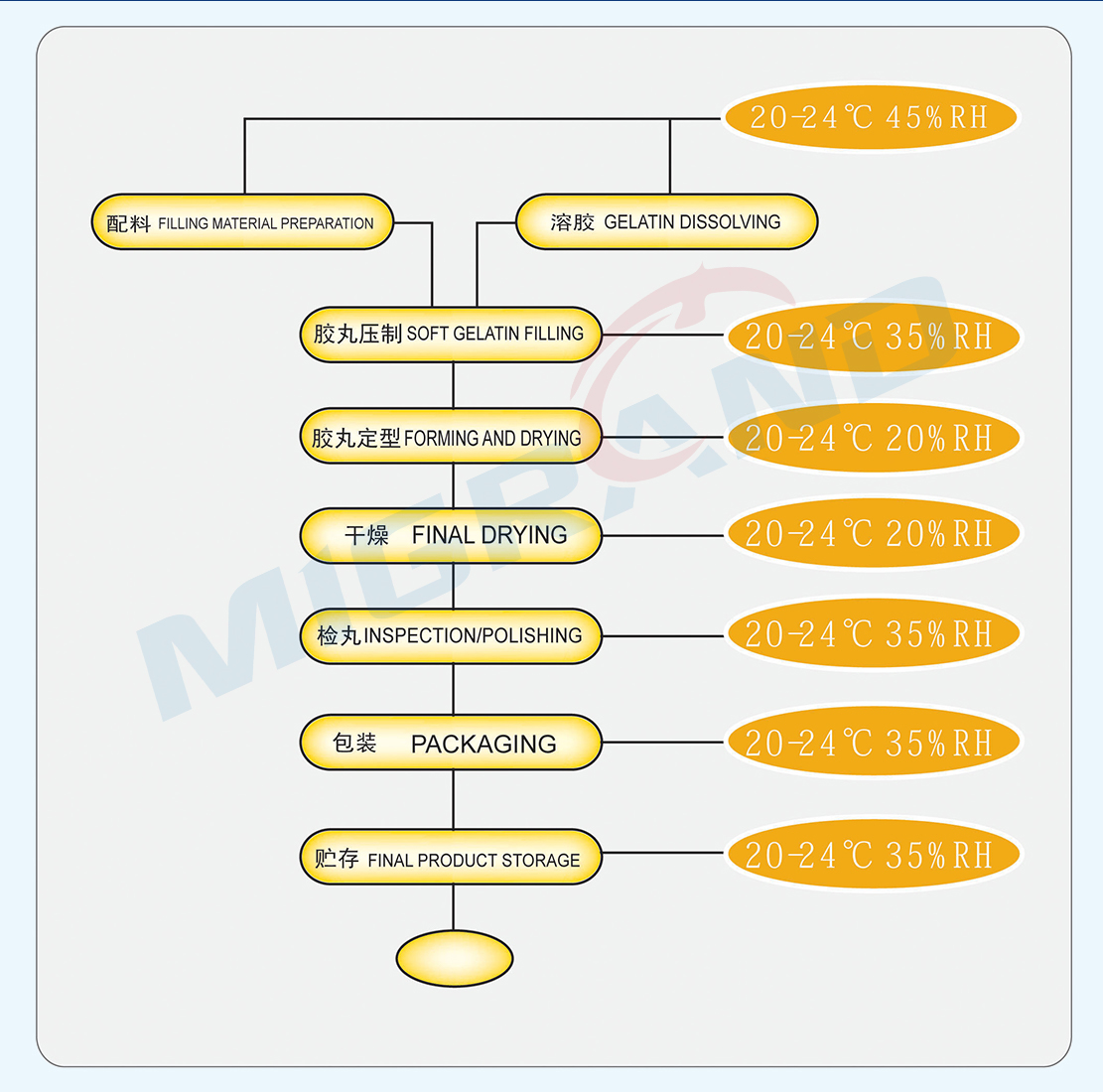

1) First of all, mixing gelatin, water, glycerin, preservatives, pigments and other excipients then boiling the mixture into gelatin liquid suitable for forming softgels using Gelatin-Melt Tank equipment. Or it can be equipped with stirring storage tanks to store the melted gelatin liquid, and then input the gelatin liquid into the gelatin box through a pressure device.

2) At the same time, we need to prepare the softgel filling materials, which refers to the preparation of the medicine and excipients into a solution, suspension or emulsion content that meets the quality standards of the softgel through special devices such as a mixing tank, colloid mill, emulsification tank, etc.

3) Subsequently, the softgel primary machine starts to work, and the gelatin liquid in the gel box is coated on the rolling mold and cooled into a gel film.

4) Next, the gel film enters the rolling mold, and the rolling die guides the convergence of the left and right films, and at the same time the liquid medicine filling system works, pumping the liquid medicine into the cavity formed by the rolling mold of the two films. Then under the operation of the rolling die, the cavity is heated and bonded, and then the pre-formed soft capsule is separated from the gel film and the mold cavity when passing through the capsule discharge device.

5) The filled capsules are sent to the drying cage by the conveyor belt for preliminary drying, and then stored in the tray for secondary drying, washing, inspection and the final process of the soft capsule packaging line, packaging for storage.

The above mentioned is the softgel production line and the whole production process.

5.7.9. Differences between liquid capsules and softgels

1) Dosage

The liquid capsule is based on an empty hard capsule shell as a container, and its size is subject to the size of the capsule shell, such as size000-5#, which is usually fixed. Softgels are made by cavity molding, so the size of the mold is determined, and the filling amount is much more flexible. Therefore, the dosage in softgels are much larger than that in liquid capsule.

2) Appearance

Secondly, the liquid capsule is only divided into sizes, and there is no difference in shape. While the softgel can be variable in many elegant and unique shapes.

3) Application

Liquid capsules are commonly used in pharmaceuticals and health supplements, while softgels are mainly health supplements, cosmetics and also health supplements. As a result, softgels have a wider range of uses.

4) Action time

Soft capsules are easy to release after entering the gastrointestinal tract, and the effect time is shorter, while liquid capsules need more time to exert their effects.

5) Production line and processes

The production of soft capsules usually requires a higher cost than liquid capsules at the same production capacity.

The end

So far, we have completed the complete course of the initial understanding of capsule filling machines. We talked about manual capsule filling machines, semi-automatic capsule filling machines, fully automatic capsule filling machines, and then liquid capsule filling machines and soft capsule filling machines. If you think it is useful to you, remember to collect it. And these are just a drop in the ocean of capsule filling machine knowledge base. We can't finish talking about it even if we talk for three days and three nights, such as the transmission mechanism of the filling machine, the dosage control device of the filling machine, the installation and maintenance of the filling machine, etc. I have a lot of video tutorials waiting to be shared.

Table of Contents

1. What is Capsule?

2. Capsule Type

3. What is a Capsule Filling Machine?

4. Capsule Maker Machine's Working Principle

5. Types of Capsule Manufacturing Machine

5.2-5.3 .Semi-automatic Capsule Filling Machine

5.4. Automatic capsule filling machine

5.5. Fully Automatic Liquid Capsule Filling Machine

5.6. Liquid capsule banding machine

English

English