Our automatic capsule filling machine, as a newly designed product, can replace the semi-automatic capsule filling machines. The automatic machines have attracted many customers since it can be applicable in many fields, such as hospitals, pharmaceutical research institutes, laboratories, colleges and universities, small pharmaceutical factories and health care plants.

How does a capsule filling machine work?

How to operate an automatic capsule filling machine can be a big problem for many new buyers. Therefore, we summarize the following capsule filling machine operation step by step for your reference:

1. After power startup, idle the machine by turning the hand wheel clockwise and inspect whether the machine runs stably and synchronously.

2. Enter the manual operation page on the touch screen and click the switch of the oil pump so that the precise driving parts can be effectively lubricated.

3. Click the buttons of the vacuum pump and the dust cleaner, and click the main machine start switch to let the machine idle for about 2 minutes at low speed. Then check whether the vacuum pump and the dust cleaner work normally. If there is abnormality, please turn off the main machine, the vacuum pump and the dust cleaner and check whether they are correctly installed.

4. How to adjust the filling volume of capsule filling machine

How to adjust the filling volume of capsule filling machine is explained as follows:

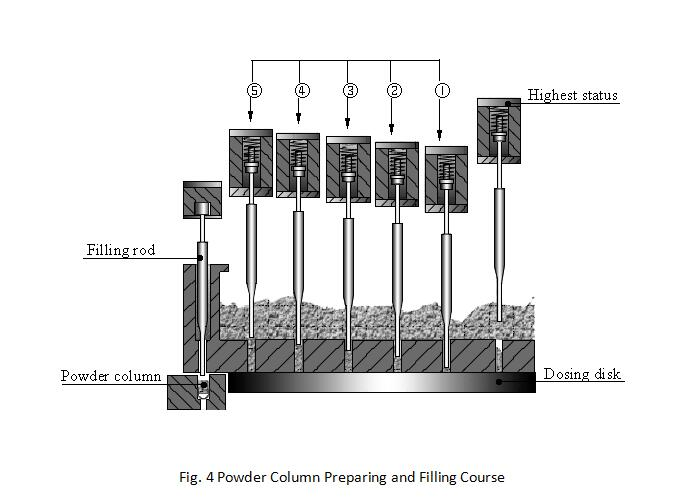

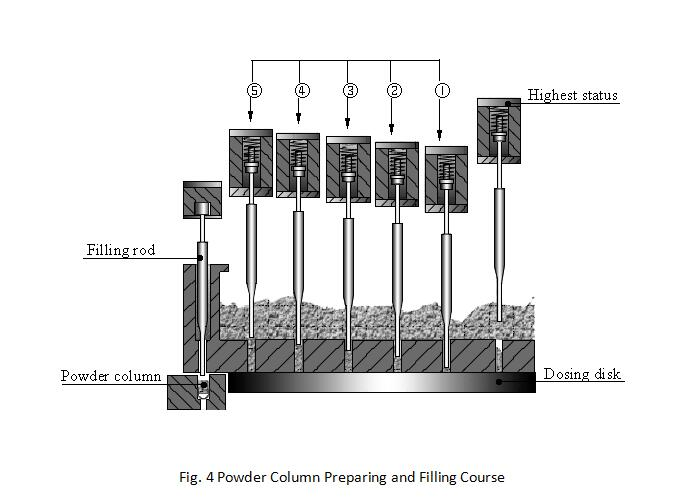

1) Jog the machine to make the filling part to its lowest position and stop. Remove the lower nuts on the upper filling part’s hand wheel and adjust the hand wheel. The smaller the scale reading of the hand wheel is, the less powder will be filled. Normally speaking, the first set of filling rods can be adjusted to about 1mm lower than the lower plane of the dosing disk, and the sixth set about 1mm lower than the upper plane of the dosing disk. The fourth set is 1-2mm lower than the fifth set and so on. If the filling weight is pretty light, fine-tune the second to the fifth sets without any adjustment to the first and the sixth sets.

2) Enter the manual operation page on the touch screen to start capsule and powder feeding into capsule hopper and powder hopper respectively.

3) Click the capsule feeding switch, vacuum pump and jog switch to make the empty capsules to be separated and operated by three stations. Then click the filling switch to start powder filling until the sensor turns red.

4) Enter the automatic operation page on the touch screen and change the frequency to 40-50Hz. Then click the start button. After the machine runs for about 10-15 minutes, sample the finished capsules and check their weight.

5) Do not clean the dust surrounding the rotary turret while the machine is running. And do not touch the driving parts with hands. Be careful to not be injured.

5. How to clean capsule filling machine

After production, clean the machine in the following steps:

1) Enter the manual operation page and change the frequency to 10-15Hz. Lift the powder hopper and turn the main motor hand wheel to lift the filling support to the highest point. Remove the bolts on the two sides of the support but add nuts as spacer. Then adjust the two bolts to the same height and place them on the lower plane of the support. At last, turn the main motor hand wheel again and disassemble the support.

2) Loosen the bolts on the two sides of the powder baffle and then remove the baffle.

3) Clean the residual powder in the powder storage ring, then unscrew the bolts with a T-type socket wrench and at last remove the dosing disk and the bottom dosing disk.

4) Remove the empty capsules from the capsule hopper and saw all the capsules in the sawing tube out. Then turn off capsule feeding.

5) Sterilize and disinfect the machine with 76% medical alcohol.

6) Jog the machine. Clean the holes of capsule dies, lower plane of the upper die and lower plane of the lower die with tools which are normally placed in the tool box and shipped to the buyers with the main machine.

7) Wipe and clean the powder hopper, filling rods, powder baffle and dosing disk with alcohol.

8) Make sure installation and production are carried out after the alcohol is dried naturally.

6. How to assemble capsule filling machine

Requirements for assembling are also come up:

1) There are five grooves under the dosing disk, corresponding to the raised dosing disk adjustment column. Make sure the columns are all inserted into the grooves.

2) Do not screw the bolts tight for the time of the installation of the dosing disk and powder baffle.

3) Turn the main motor hand wheel to make the filling support at the highest point. Install the support and fasten the bolts. Then lower the support slowly and make sure the filling rods are inserted into the inner holes of the dosing disk. Screw the bolts of the dosing disk when the filling rods reach their lowest point. Besides, make sure the filling rods are in the center of the inner holes of the powder baffle for no friction between them.

4) After installation, turn the hand wheel and make the machine idle for 3-5 stations. Make sure there is no abnormality and then start production.

Click the picture to view the product details

English

English