1. What is Capsule?

2. Capsule Type

3. What is a Capsule Filling Machine?

4. Capsule Maker Machine’s Working Principle

5. Types of Capsule Manufacturing Machine

5.2-5.3 .Semi-automatic Capsule Filling Machine

5.4. Automatic capsule filling machine

At present, the popular automatic capsule filler in the market are named according to the capacity per minute, such as NJP400, NJP800, NJP1200, NJP2000, NJP2500, NJP3500, NJP5000, NJP7500, etc. The number means the capacity per minute, e.g. 1200 means that the machine production capacity 1200 capsules/min, so the machine can fill 24K to 450K capsules per hour. Therefore, the automatic capsule filling machine becomes the best choice for large capsule production plants.

All these models have their own strengths and advantages with variable subdivision functions, customers may don't know how to choose a suitable one. We will provide another article about the recommended ten best capsule filling machines, please pay attention for the updates.

As above mentioned, the automatic capsule filling machine can fill soft capsule, liquid capsule and automatic powder/granule capsule, and the powder/granule capsule manufacturing machine is the most widely selected. Filling powder into capsules is only one application, with optimization and adjustment of the dosing and filling system, it is possible to also fill capsules with granules, tablets, micro-capsules.

More advanced than a semi-automatic capsule filler machine is that the operator only need perform simple operations on the touch screen. The entire process of capsule filling can be completed by program control almost without human involvement. As a result, such a machine can significantly increase productivity and reduce labor costs.

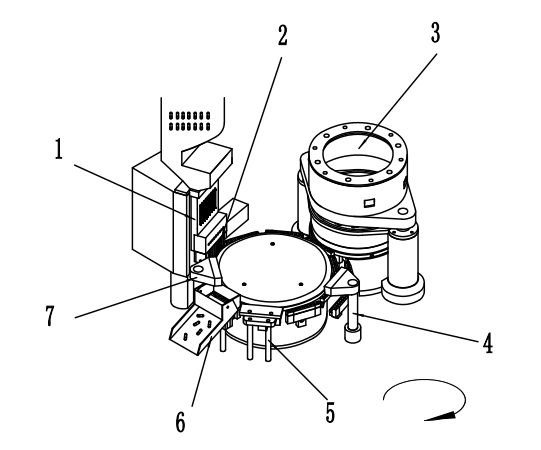

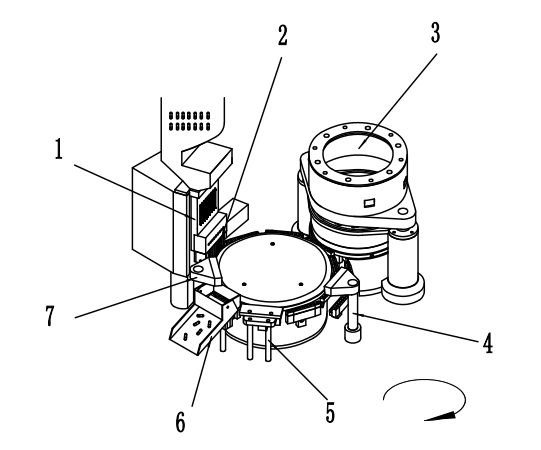

5.4.1. Working process

1) Capsule feeding and arranging device; 2) Vacuum capsule separating;

3) Metering powder for filling; 4) Defective rejection device;

5) Capsule locking device; 6) Capsule discharging device; 7) Mold cleaning device

5.4.2. Capsule feeding and arranging

Capsules are randomly fed from the feeding hopper onto the conveyor plate with multiple inward circular channels for capsule arranging in front segment. The lower end of each channel is fitted with a spring leaf. When the capsule conveyor plate reciprocates up and down, capsule enters the channel and gets stuck by the spring leaf. The conveyor plate is then moved downwards to make the spring leaf release the capsule, which falls into the middle segment of the arranging device.

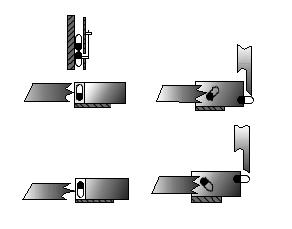

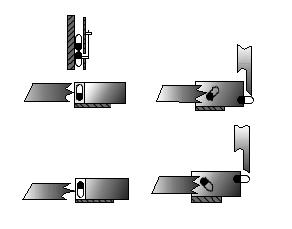

As shown in the diagram below, the capsule falls disorderly into the front end of the horizontal fork. The special structure of the fork allows it to act on the middle part of the capsule body with a smaller diameter then capsule cap. Under the gravity difference, the capsule body moves forward and the capsule cap backward. The capsule direction can be adjusted with the vertical fork action. In this way, all capsules enter the next segment in the direction that capsule body facing down and capsule cap on top. Now it completes the capsule arranging process.

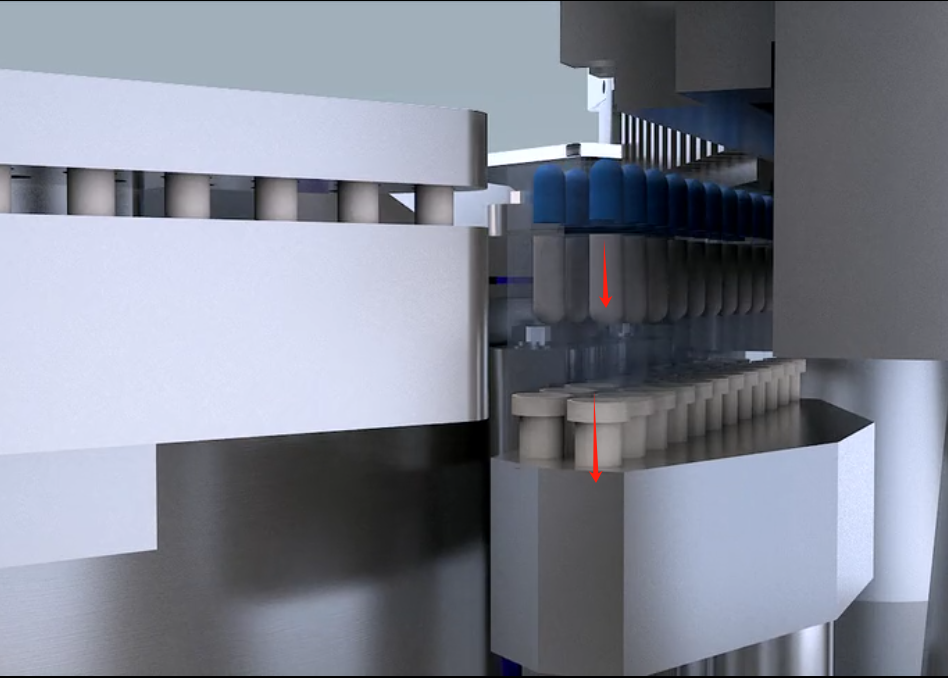

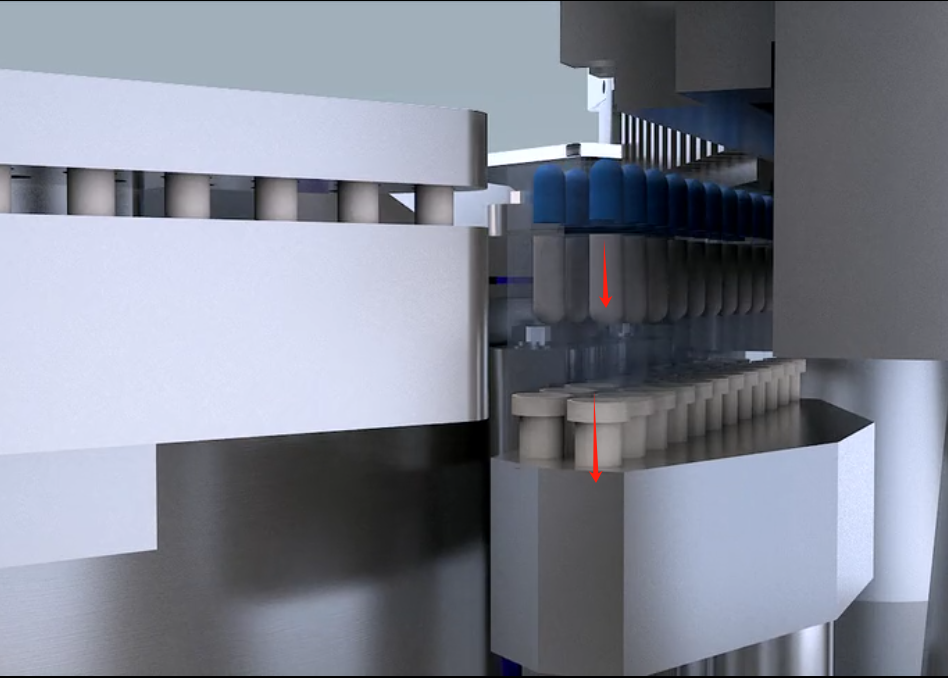

5.4.3. Vacuum capsule separating

The procedure is to separate the capsule cap from the capsule body. When the capsules are inserted into the capsule tray in the direction of cap on top and body down, the capsule tray is transferred to the capsule separation station, and the capsule caps are kept in the upper part of the capsule tray. The vacuum slider then sucks the capsule body under negative pressure through the vacuum pump, so that the capsule separates normally without breakage.

5.4.4. Metering powder for filling

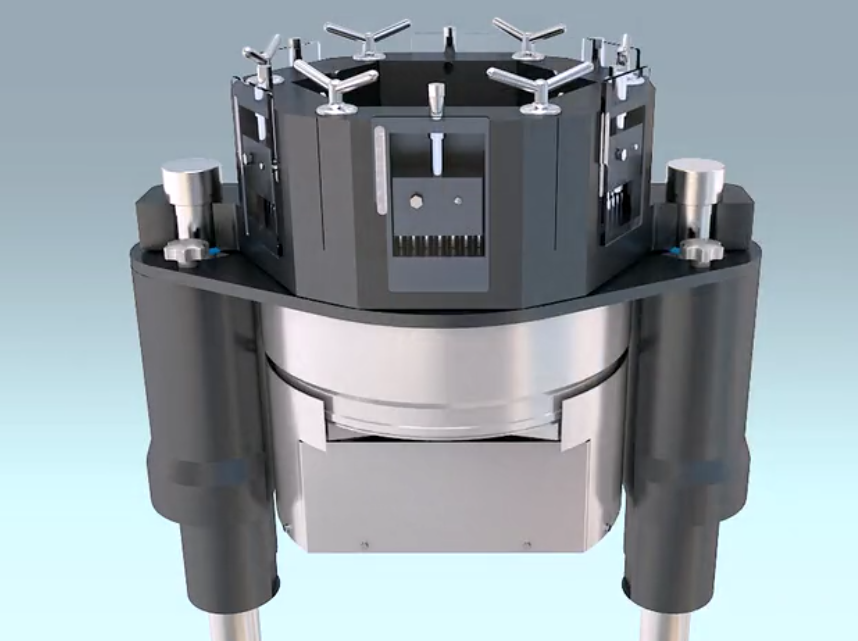

The capsules are transferred to the filling station through a turntable. A dosage disc is adopted to fill the capsule. The filling volume depends on the capsule size.

5.4.5. Defective rejection device

For unseparated capsules, the pins at this station will eject them from the tray, which will be sucked into the collecting bag.

The device is composed of the ejecting pin, handle, guide pillar, positioning block, pull rod and other parts.

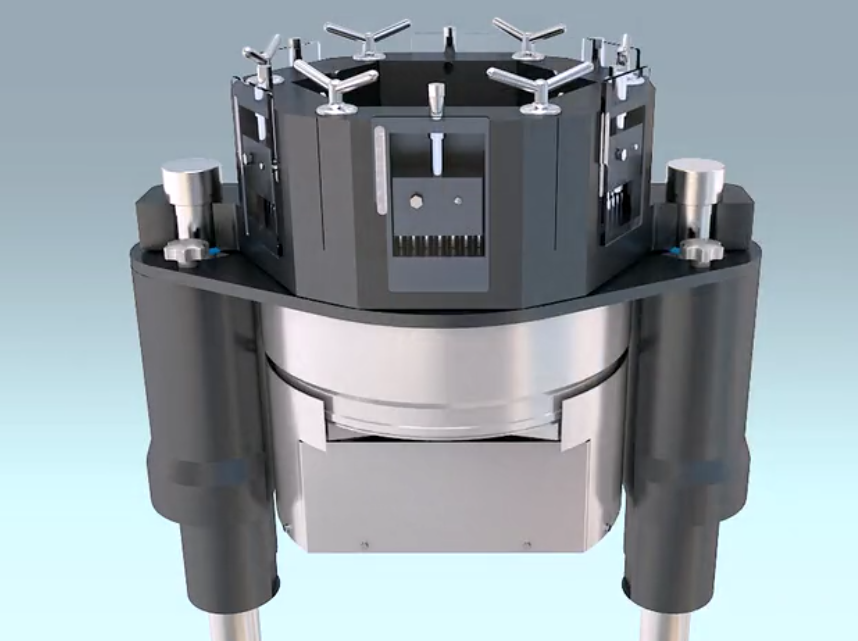

5.4.6. Capsule locking device

After filling the capsules, the tray for body and cap reach the capsule locking station at the same time, the baffle above the capsule tray prevents the capsule from being ejected, and the pins under the capsule tray move upwards to lock the capsules.

5.4.7. Capsule discharging device

The capsule has been finished after being locked in the last position and is pushed out by this station. A pin under the station pushes the capsule out of the tray, and compressed air above the station blows the finished capsules out of the discharge port.

5.4.8. Mold cleaning device

Once the capsule is discharged, there may still be defective capsules or powder residue in the capsule tray, which therefore needs to be cleaned before the next production. Compressed air blows the remaining powder and defective capsules into the recovery device located at the bottom.

This is how an automatic capsule filling machine works. The whole process is completed very quickly and automatically after start-up. Of course, in order to achieve unmanned and fully automatic production, it is necessary to equipped with empty capsule loader, vacuum loader, etc. before the capsule arranging device (the loader should match the different fillers). After the capsule discharging device, capsule polishing/inspection device can be equipped, for the next packing process through different finished capsule feeding device, such as blister packaging machine, counting and bottling machine line, etc. And after passing through a detection device, it enters the cartoning machine and box incasing machine at the end of the automatic production line. Finally it is sent to the warehouse or for entrucking after the stacking and winding machine.

Actually, the above mentioned production process is not only the production process of the automatic capsule filling machine, but also involves the process of the entire capsule filling and packing line. If you are interested in learning more about the pharmaceutical production line, please visit our official website and add my social accounts for easy communication.

updating......

English

English