CIP Cleaning System: the Essential Choice for Enhancing Efficiency and Hygiene Standards

CIP systems are typically used for cleaning of liquid front end handling equipment and rear end filling machine lines.So when we begin to explain CIP, it is necessary to talk about the front-end processing equipment of liquid-emulsifying machine.

What is an Emulsifying Tank / Homogenize Machine?

The emulsifying tank is used to uniformly stir two or more immiscible liquids (such as oil and water). Through high-speed shearing, stirring, and homogenizing, the tank disperses the mixed liquids into tiny particles to form stable emulsion. It is widely selected in food, cosmetics, pharmaceuticals, and chemicals industries for producing sauces, creams, ointments, coatings, etc.

Applications of Emulsifying Tank

- Food: Used for making mayonnaise, salad dressings, ice cream, etc.

- Cosmetics: Used for producing lotions, creams, shampoos, etc.

- Pharmaceuticals: Used for manufacturing ointments, emulsions, etc.

- Chemicals: Used for producing coatings, adhesives, etc.**

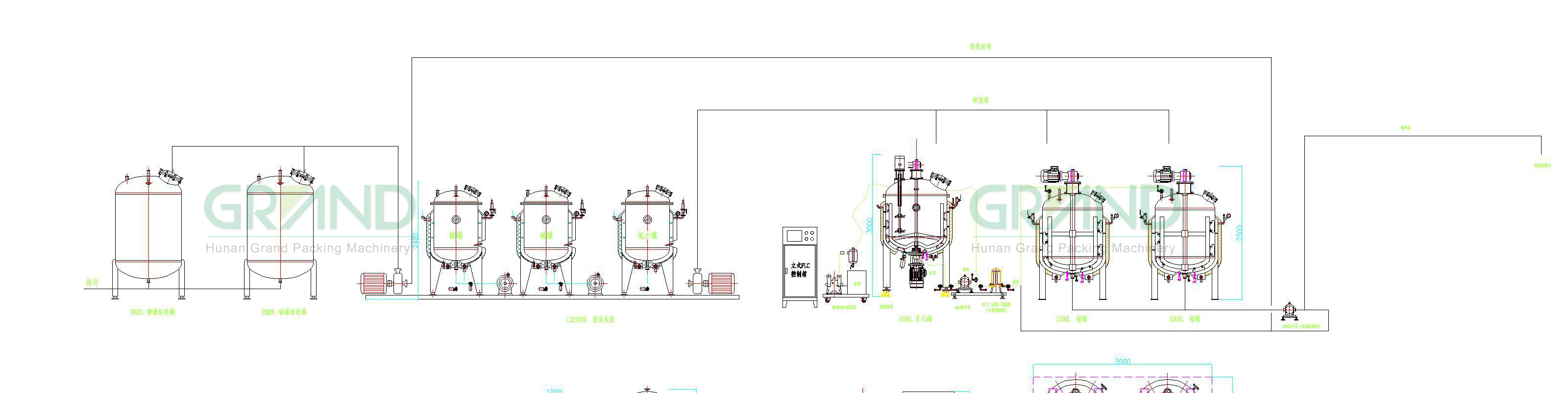

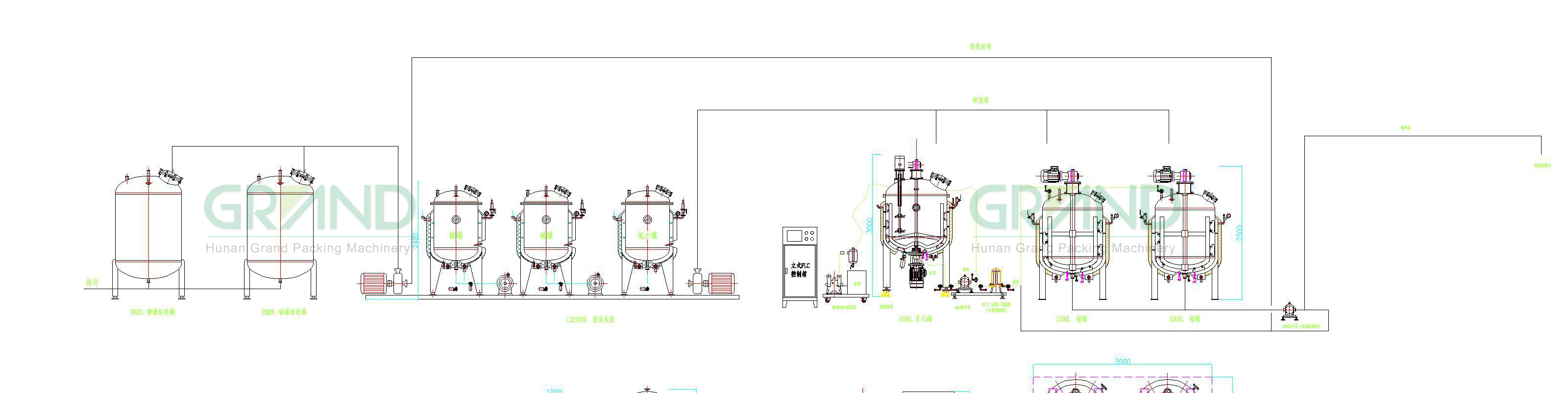

Upstream and Downstream Equipment for Emulsifier

Emulsifying tank is typically equipped with the following equipment to constitute a complete production line:

- Upstream equipment: Raw material storage tanks, metering pumps, filters, etc.

- Downstream equipment: Finished products storage tanks, filling machines, packing machines, etc.

CIP Cleaning System: An Efficient Cleaning Solution for Emulsifiers

In factories with high production standards and requirements, emulsifiers often need to be equipped with a CIP (Clean-In-Place) system to ensure thorough cleaning and hygiene. Our CIP cleaning system is priced at 396,000 RMB and comes with two recovery tanks of 2000L volume (total pricing 65,000 RMB), which can meet the requirements of high-standard production.

CIP Workflow

1. Pre-rinse: Adopts high-pressure water injection or circulating flushing to initially remove food residues, grease, and other contaminants out of the device.

2. Alkaline washing: Circulates hot water (75~80℃) mixed with alkaline detergent (e.g., sodium hydroxide) for washing, to remove oil and protein residues.

3. Intermediate water rinse: Adopts fresh water to rinse away the detergent from pipes and containers, ensuring cleaning effect.

4. Acidic washing (Optional): Uses acidic detergent (e.g., nitric acid) at 60~80℃ to remove calcium salts and mineral residues, and neutralizing pH at the same time.

5. Fresh water rinse: Uses fresh water to thoroughly clean residual sterilizing agents.

Technical Requirements for the CIP System

- All parts in contact with materials must be made of 316L stainless steel.

- Pumps and valves must meet CIP standards, adopts quick-connect fittings instead of threaded connections.

- Adopts PTFE gaskets for better sealing effect and durability.

Recommendations

We recommend that customers should consider whether to equip their emulsifiers with a CIP cleaning system based on their production requirements and hygiene standards. If encounter any problems during the emulsifier operation, please feel free to contact us. We will provide professional technical support and solutions.

Please contact us to learn more about the emulsifier CIP cleaning system!

English

English