Tube test kit filling and capping machine for corona virus

This is a full automatic test kit tube filling and capping machine, the working processes are as following:

Tube feeding by vibrating feeder-- tube locating and placing--test kit solution liquid filling--auto cap feeding and screwing--final product output

We can also connect the final filled and capped tube for the next labeling machine.

1. Introduction

This machine is advanced, reliable, reasonable and human-friendly as GMP requires. The influence of human factors is reduced during operation. It can fill, feed cover, pre-cap and discharge bottles automatically. These stations are connected so that all motions can be finished synchronously;

1) Convenient equipment operation

Capping force, capping speed, production speed, error and output can all be displayed on operation panel. These parameters can be adjusted on the panel. A PMMA door is installed on the operation table for convenient observing machine production;

2) Adjustable structure

This machine can fill and cap bottles of eye drops, essential oil, lotion, cosmetic liquid, lodine, tincture... The production speed, capping speed and force can all be adjusted on operation panel according to practical production;

3) This machine has compact structure. It cost 0.5s from filling station to the cover feeding station;

a. The parts contacting material are all made of good-quality stainless steel and special silicone pipe;

b. The machine applies reliable piston to fill, and the filling volume and speed can be adjusted conveniently;

c. The filling parts can be dismantled, cleaned, disinfected, sterilized and installed easily;

d. The lifting filler can insert into bottles for effective filling;

e. Our pre-capping structure, a patent, can increase pass rate of capping;

f. Servo motor is applied for capping. The capping speed and force can be directly controlled on HMI;

g. The machine uses PLC for automatic control, is made of stainless steel and is equipped with a clear PMMA cover;

h. The machine is equipped with an error alarming device and a shutdown device which functions when machine door is opened or machine is mechanically overloaded;

i. Piston is used to fill material in fixed amount;

j. The machine doesn’t fill without bottles.

4) Lift capping device is controlled by cam and its structure is stable. Eccentric cam drives the machine for low noise and long service life. Dropper cap is fed through single channel.

5) Overload protection of star-like plate on the main driving system can avoid mechanical errors caused by bottle sticking and stop the machine timely for troubleshooting.

2. Technical parameters

Model | ZHJY-100 |

Filling volume | 2-10ml |

Production speed | 60-70 bottles/min |

Filling accuracy | ≤ ±1% |

Proper bottles | φ10-42mm |

Power supply | 220V, 50Hz |

Automatic capping rate | ≥99% |

Automatic stoppering rate | ≥99% |

Air source | 1.3m3/h, 0.4-0.6MPa |

Power | 2.0KW |

Net weight | 1000Kg |

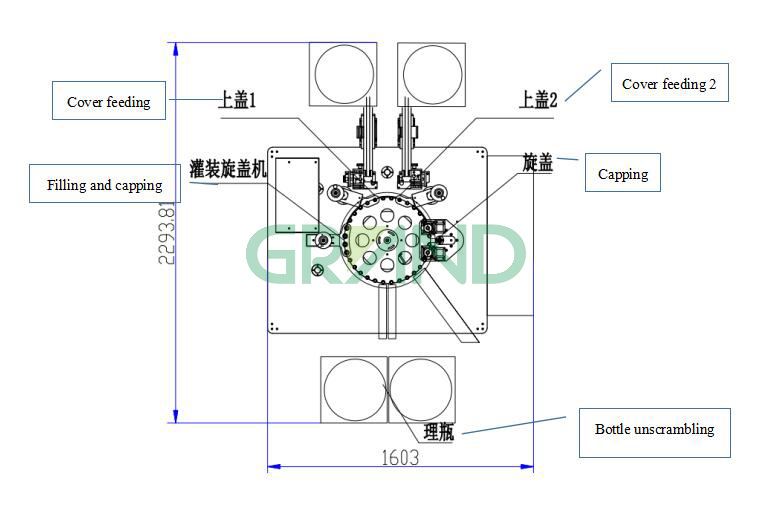

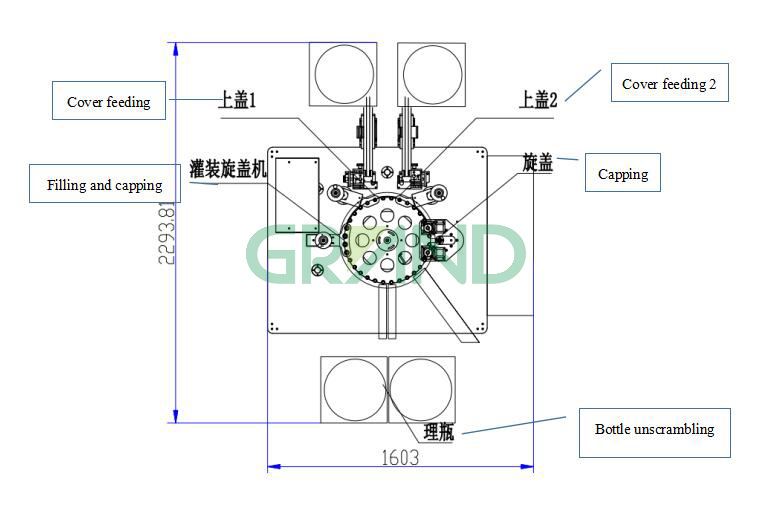

Overall dimensions | 2400*2000*1900mm |

3. Pictures

Tube vibrating feeder

Details for filling and capping

Cap vibrating feeder

Peristaltic pump filling for test kit solution liquid

Our Services

Service 3: We will dispatch engineers to your site for machine installation and commissioning, and also do the training for your technicians.

Service 4: We makes guarantee of the machine for 12 (twelve) months. During this Warranty period, the seller will provide free spare parts that cause by the machine’s quality within 10 days by fast courier upon receipt of buyer’s notice.(we will also provide one set of spare parts /wear &tear parts to customer along with the shipment of the machine.

Service 5: We warmly welcome the suggestions from customer to make us grow better and produce better machine along with providing better service to customer, and create more value for customer.

Service 6: Before placing the order or before shipping, welcome to our factory to take a visit to inspect our machine. we will pick you up in the airport or train station and arrange your following schedule in our city to bring you a nice journey during this visit.

Company Information

ABOUT US

Hunan Grand Packing Machinery Co.,Ltd is specialized in the pharmaceutical and packing machinery for more than 10 years, such as plastic ampoule forming filling and sealing machine, capsule filling machine, blister packing machine, strip packaging machine, cartoning machine etc. We have provided services and machines to many different countries and regions in the whole world, such as Indonesia, Thailand, Malaysia, Philippines, New Zealand, Korea,the Middle East area, Poland, Belgium, France, UK, Greece, Italy, Turkey, USA, central and south America such as Trinidad and Tobago,Mexico, Brazil, Russia, Ukraine, UZ, Tunisia, Algeria, Morroco etc. And we always gain the good reputation from customer both from the machine quality and after sales service.

customer visit at our factory and our visit to customer

Our factory

We are cooperating with various kinds of factories and companies in different fields, including pharmaceutical factory, food factory, supplement factory, agrochemical factory such as for pesticide, fertilizer, personal care product factory, such as for cosmetic product, daily use product, stationery factory, hardware factory etc.

English

English