Comparative Analysis of Cartoning Machines: Balancing Stability, Durability, and Cost

In the packaging machinery industry, cartoning machines are indispensable equipment in production lines. With the diversification of market demands, the design, materials, craftsmanship, and performance of cartoning machines continue to evolve. This article will compare the differences between our equipment and that of competitors from six aspects: overall machine weight and dimensions, material of external and structural components, processing technology of parts, box-opening and box-pressing structures, product-pushing stations, and electrical components. This will help users better understand the strengths and weaknesses of different machines.

1. Differences in Overall Machine Weight and Dimensions

Our Equipment:

To ensure operational stability, our cartoning machine is designed with a strong emphasis on the robustness of its workstation structure. The machine weighs 1.5 tons, and this substantial weight not only enhances stability but also effectively reduces vibrations during operation, ensuring long-term efficiency. Although the machine is heavier, this design ensures reliability in high-intensity working environments.

Competitors' Equipment:

Competitors' machines prioritize cost savings by minimizing the structure and length of workstations, keeping the total weight under 1 ton. While the lightweight design reduces material costs, it may lead to insufficient stability during prolonged operation, especially at high speeds, where vibrations and displacement could affect production efficiency and product quality.

Comparison Summary:

Our machine improves stability through increased weight, making it suitable for high-intensity, long-term production environments. Competitors' machines reduce costs through lightweight designs but may sacrifice stability and durability.

2. Differences in Material of External and Structural Components

Our Equipment:

We use stainless steel or anodized aluminum for the entire machine, which not only increases weight and stability but also prevents rust contamination from iron components. The use of stainless steel and aluminum enhances the machine's aesthetics and extends its lifespan, making it ideal for industries with high hygiene requirements, such as food and pharmaceuticals.

Competitors' Equipment:

Competitors' machines often use painted or blackened iron components. While this treatment reduces costs, iron components are prone to rust over time, compromising product hygiene and potentially damaging the machine's structure, leading to higher maintenance costs.

Comparison Summary:

Our machine prioritizes durability and hygiene standards in material selection, catering to high-demand industries. Competitors' machines reduce initial costs with cheaper materials but may face rust and maintenance issues in the long run.

3. Differences in Processing Technology of Parts

Our Equipment:

To ensure the accuracy of structural component installation, every reference plate and fixture is machined to guarantee consistent dimensions. This high-precision processing technology enhances stability, extends the machine's lifespan, and reduces failures caused by part inaccuracies.

Competitors' Equipment:

Competitors cut costs by lowering the processing standards for reference plates and fixtures. This simplified approach may result in unstable operation, non-standardized parts, and increased repair difficulty and costs.

Comparison Summary:

Our machine ensures part consistency and stability through high-precision processing, reducing maintenance frequency. Competitors' machines may suffer from operational instability due to insufficient processing precision.

4. Differences in Box-Opening and Box-Pressing Structures

Our Equipment:

Our box-opening and box-pressing structures are more rationally designed, with larger spaces and more scientific installation positions. This design ensures stable operation and facilitates debugging and maintenance. The spacious design minimizes the risk of displacement or deformation during long-term operation, ensuring continuous production.

Competitors' Equipment:

Competitors' machines feature compressed-space designs with shorter workstations. While this saves space, prolonged use may cause displacement or deformation of components, affecting production efficiency and product quality. Additionally, the cramped space complicates debugging and maintenance.

Comparison Summary:

Our machine improves operational stability and maintenance convenience through rational spatial design. Competitors' machines may face operational issues due to insufficient space.

5. Differences in Product-Pushing Stations

Our Equipment:

We employ an advanced pusher head structure installed on the upper part of the machine, co-axially driven with the main unit. This rational design ensures long-term stability and simplifies debugging specifications, reducing manual operation and maintenance costs.

Competitors' Equipment:

Competitors' machines still use a 20-year-old transmission method, featuring complex structures and cumbersome debugging and troubleshooting processes, which increase unnecessary labor costs and time consumption.

Comparison Summary:

Our machine enhances operational convenience and stability with modern pusher head structures. Competitors' machines, due to their complex designs, increase debugging and maintenance difficulty.

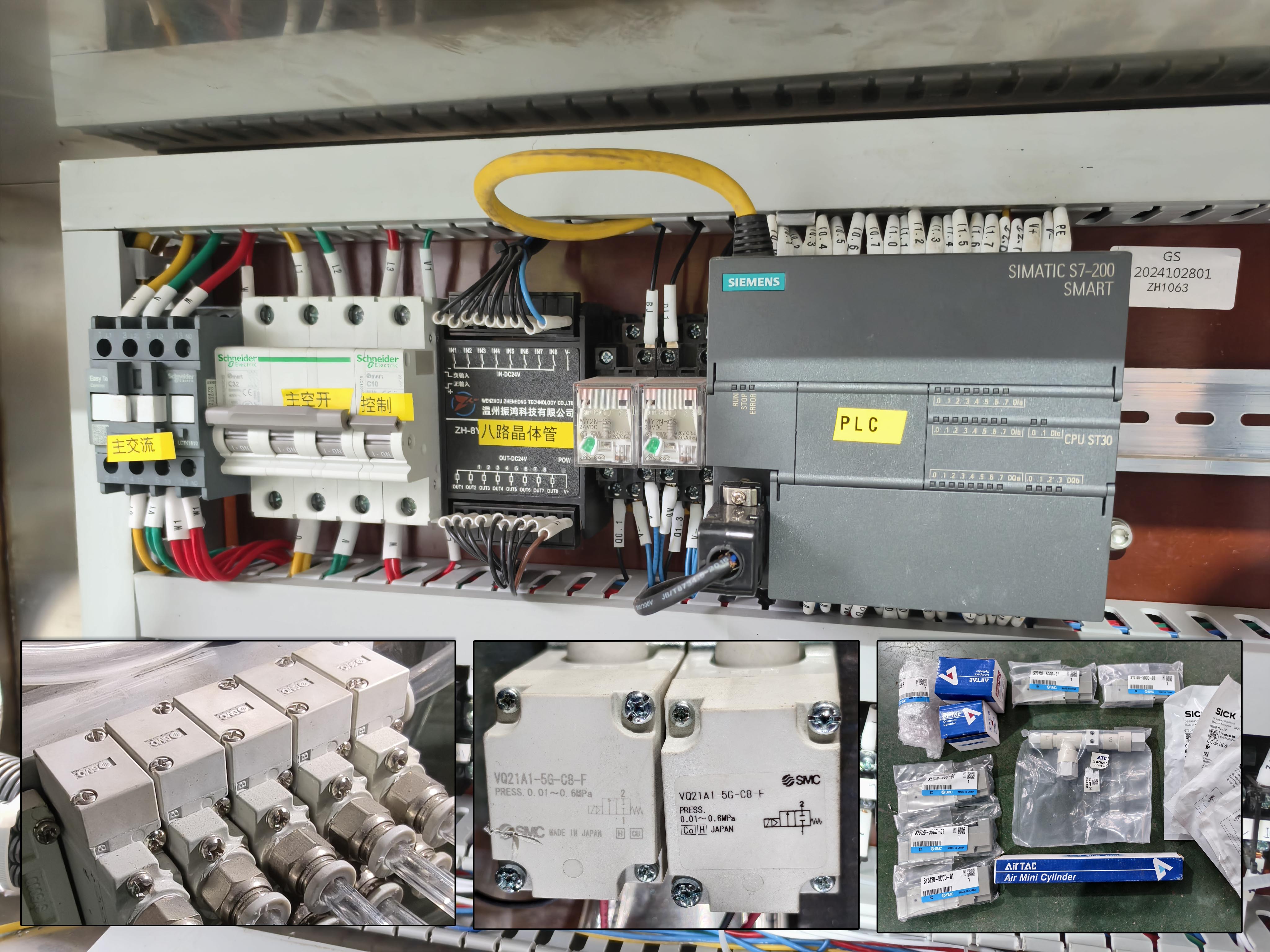

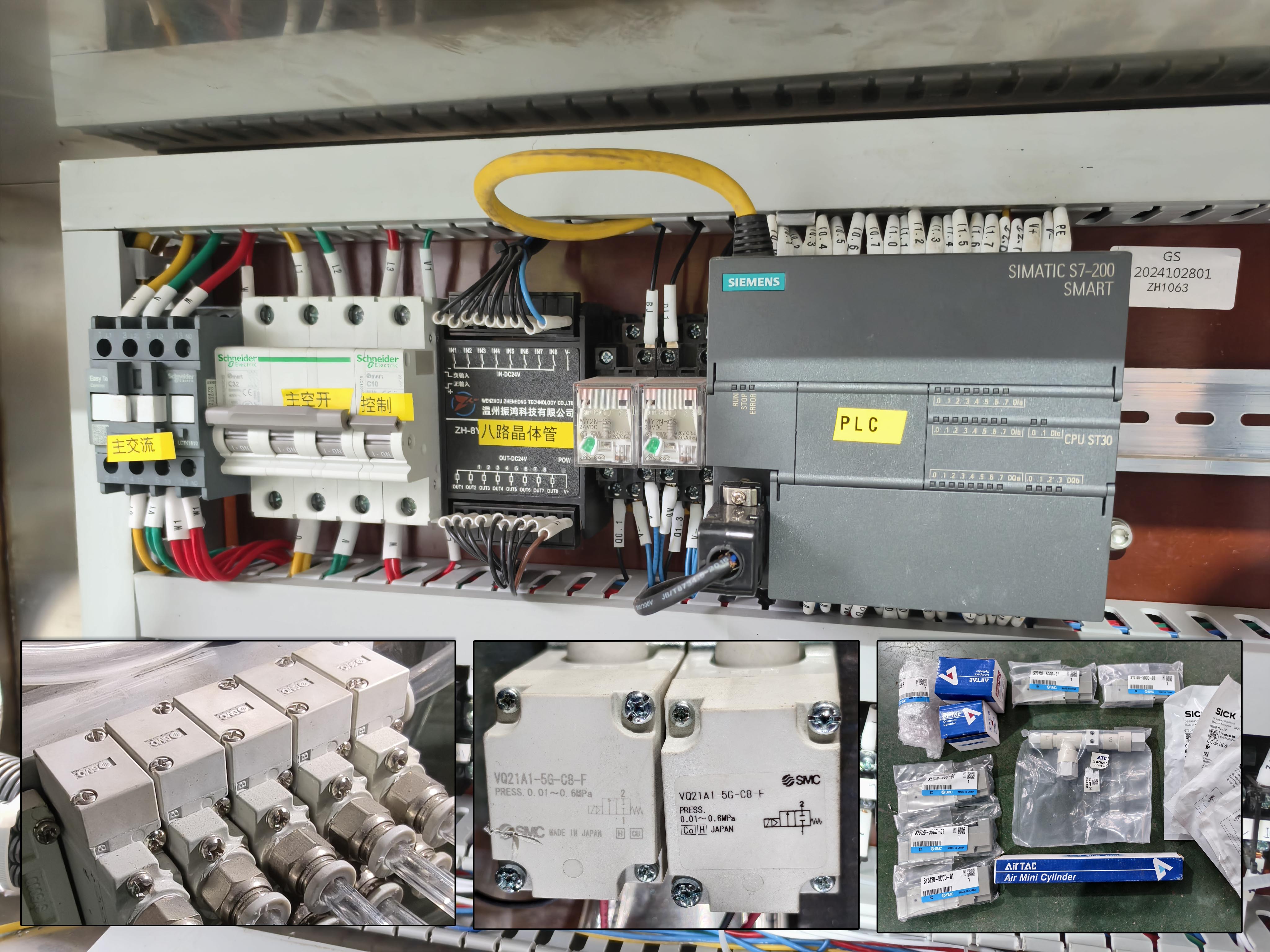

6. Differences in Electrical Components

Our Equipment:

We use internationally renowned electrical brands to ensure long-term operational stability and reliability. High-quality electrical components reduce failure rates and maintenance costs while improving overall performance.

Competitors' Equipment:

Competitors' machines often use low-end domestic brands or counterfeit products, resulting in inconsistent electrical quality, potential safety hazards, and frequent failures over time, increasing repair costs and production risks.

Comparison Summary:

Our machine ensures high reliability and low failure rates with top-tier electrical brands. Competitors' machines may face higher repair costs and safety risks due to unstable electrical component quality.

Conclusion

The comparison across these six aspects highlights the clear advantages of our cartoning machine in terms of stability, durability, maintenance convenience, and safety. While competitors' machines may be more cost-attractive initially, our equipment delivers higher production efficiency and lower maintenance costs in the long run. For users seeking high quality, stability, and long-term benefits, our machine is undoubtedly the superior choice.

If you are also interested in Different Cartoning machine(Horizontal, Vertical, Rotary), please contact me.

Mobile/Wechat/Whatsapp: 0086-13787413551

Email: sales@grand-packing.com

English

English