Overview

JDZ 260 automatic high speed cartoning machine is an innovative design of our company on the basis of introduced advanced foreign technologies. It is manufactured according to pharmaceutical requirements of GMP. The machine has production capacity of high efficiency and good performance. Its technologies related to instructions folding and conveying, cartons forming and material pushing structure at the rear have all met European and American standards. Compact appearance design and continuous material pushing structure at the rear simplify operation and maintenance. Four divided double rotary planetary gear can open cartons outwards. And a second pre-formation device is equipped. These two designs can make sure that cartons can be opened and formed completely.

Application

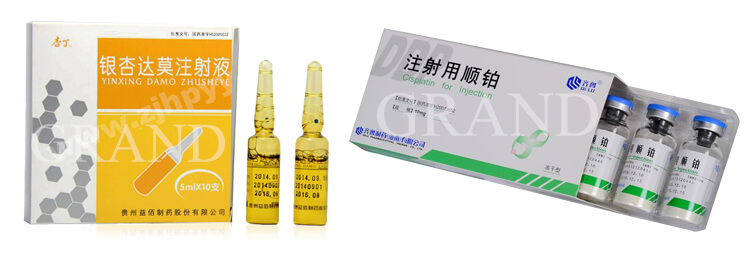

It is an automatic continuous high speed vial and ampoule cartoner and a high-performance equipment of machinery, light, electricity and air. It can be applied to carton various kinds of product such as medicine bottles (round/square), cosmetics, foodstuff, health care products and bottle-like material automatically, and to match with related machines to form a packing production line. Here we focus on introducing the automatic box packing for glass vial and ampoule. It is the right box packing equipment for pharmaceutical company to have big scale production of vial and ampoule box packing, which completely and strictly meet with the GMP requirement.

Main technical feature

1. The machine will not suck instructions without product and not suck cartons without instruction;

2. The machine will idle and not push products when there is no product or the product is not supplied as set. It will operate automatically after its returning to normal supply of products, while it stops when cartons are not supplied as set.

3. The machine stops without cartons or continuously without instructions for many times.

4. The machine stops and alarms when the compressed air pressure or vacuum negative pressure is too low.

5. Material pushing structure at the rear can save more space for the machine front. Such a design is human-friendly to make operation and maintenance of operators more convenient.

6. Product specifications can be changed easily through dial hand wheel.

7. Main transmission system has an overload protection device to secure machine and operation.

8. Servo material feeding system: Oscillating and tracking feeding device is applied. Compared with similar fixed feeding devices in the market, our device can feed faster and more accurately. It can also feed a piece or multiple pieces of material once into the material conveying chain groove.

9. Main motor, PLC, frequency converter, sensor, relay, contactor and pneumatic components are all produced by international famous brands.

10. The machine can display cartoning speed, alarm errors and count automatically.

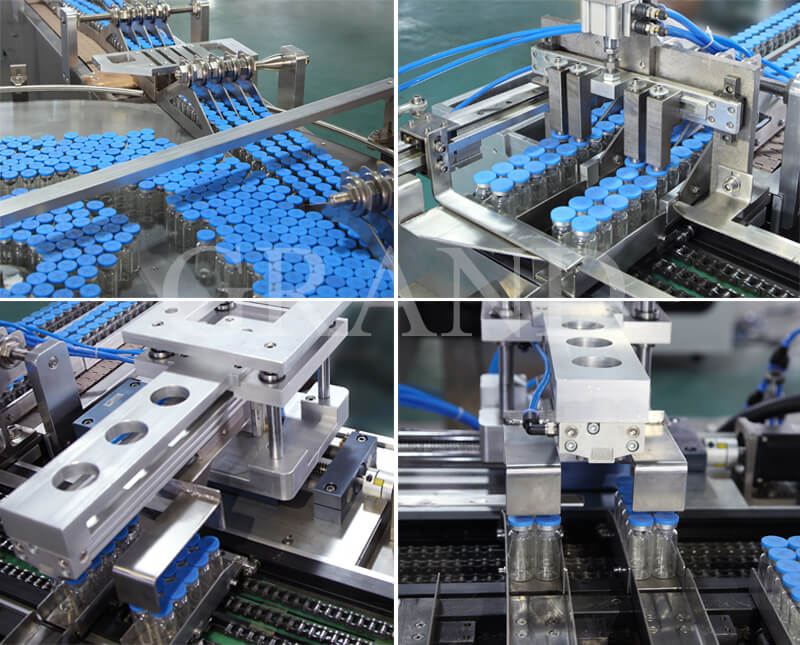

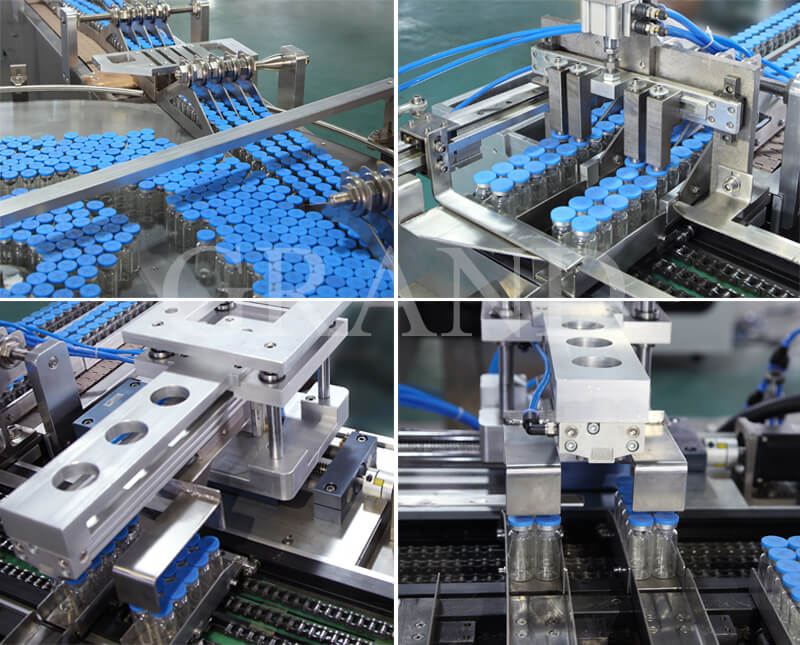

Vial feeding on the turn table---vial collecting and assembling---assembled vials pushing into the box

Technical parameters

Items | Parameters |

Highest cartoning speed | 260 cartons/min |

Carton | Quality requirement | 250-350g/m2 (depending on the carton size) |

Dimensions (L*W*H) | (70-180)*(35-80)*(14-50)mm |

Instructions | Quality requirement | 60-70g/m2 |

Unfolded size (L*W) | (80-250)*(90-170)mm |

Folds | 1-4 fold(s) |

Compressed air | Operation pressure | ≥0.6mpa |

Air consumption | About 160-200L/min |

Power supply | 380V, 50Hz |

Total power | 5KW |

Overall dimensions (L*W*H) | 6800*1600*1860mm |

Net weight | About 3400Kg |

Company Information

ABOUT US

Hunan Grand Packing Machinery Co.,Ltd is specialized in the pharmaceutical and packing machinery for more than 10 years, such as plastic ampoule forming filling and sealing machine, capsule filling machine, blister packing machine, strip packaging machine, cartoning machine etc. We have provided services and machines to many different countries and regions in the whole world, such as Indonesia, Thailand, Malaysia, Philippines, New Zealand, Korea,the Middle East area, Poland, Belgium, France, UK, Greece, Italy, Turkey, USA, central and south America such as Trinidad and Tobago,Mexico, Brazil, Russia, Ukraine, UZ, Tunisia, Algeria, Morroco etc. And we always gain the good reputation from customer both from the machine quality and after sales service.

Our Service

1.We will dispatch engineers to your site for machine installation and commissioning, and also do the training for your technicians.

2.We makes guarantee of the machine for 12 (twelve) months. During this Warranty period, the seller will provide free spare parts that cause by the machine’s quality within 10 days by fast courier upon receipt of buyer’s notice.(we will also provide one set of spare parts /wear &tear parts to customer along with the shipment of the machine.

3.We warmly welcome the suggestions from customer to make us grow better and produce better machine along with providing better service to customer, and create more value for customer.

4.Before placing the order or before shipping, welcome to our factory to take a visit to inspect our machine. we will pick you up in the airport or train station and arrange your following schedule in our city to bring you a nice journey during this visit.

English

English