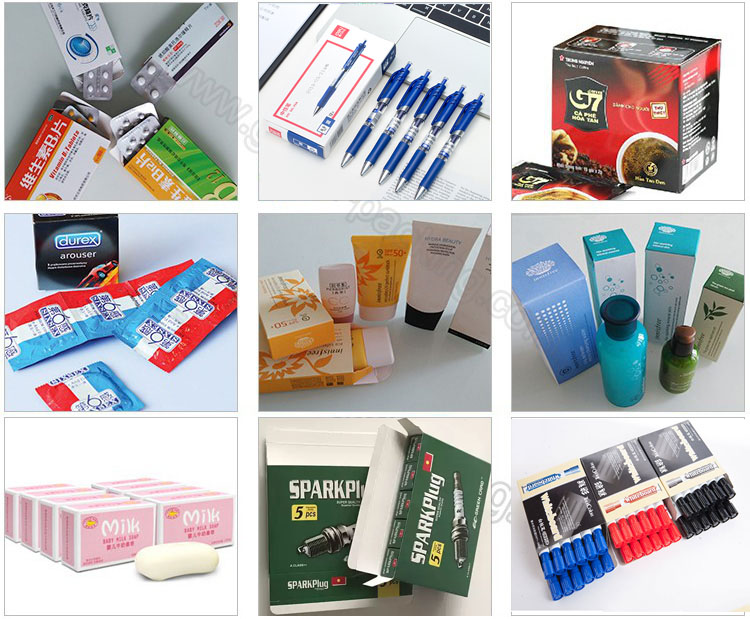

Application

JDZ-120G automatic horizontal cartoning machine is a high-tech product of light, electricity, air equipment. It is applicable to carton the tube/irregular shape bottle/jar/soap/sachet or other irregular shape of product such as stationery,toy, hardware, for example,pen, pencil, car brake,valve, bearing,pencil/eyebrow pencil, birthday candle etc, as well as the soft package or product with tray automatically.

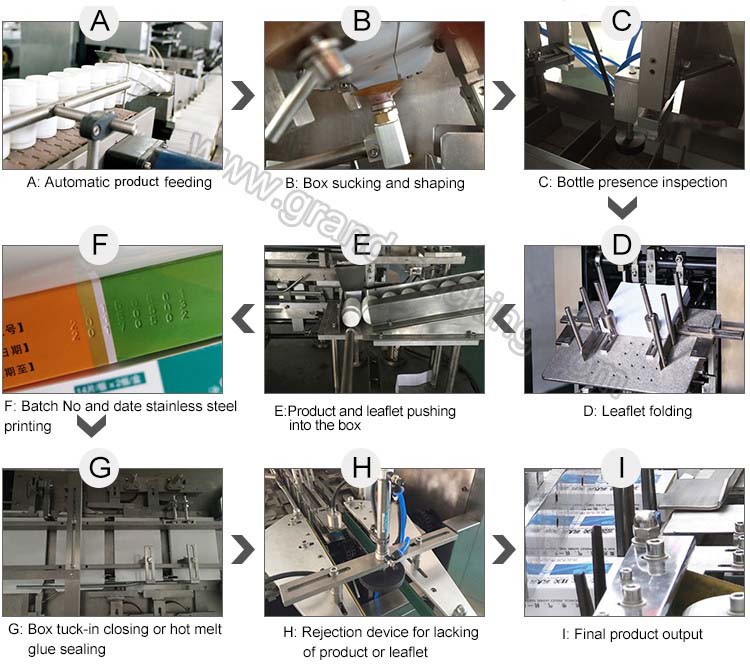

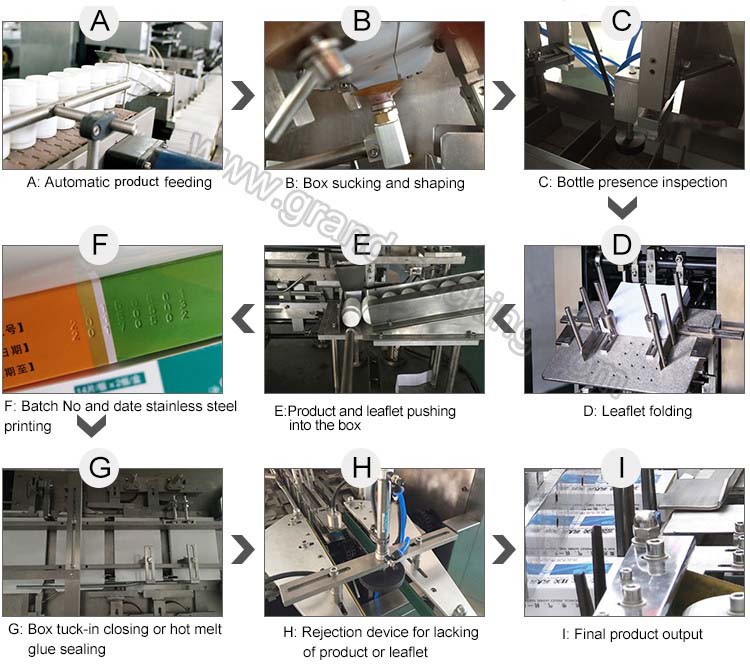

The machine working process

It can finish a series of complicated process, including product feeding, transferring on the conveyor, folding leaflet (into 1-4 fold(s)) and box sucking, opening, shaping and product pushing into the box, batch No embossing or ink jet printing( optional), box tuck-in closing or hot melt glue sealing, and final product output.

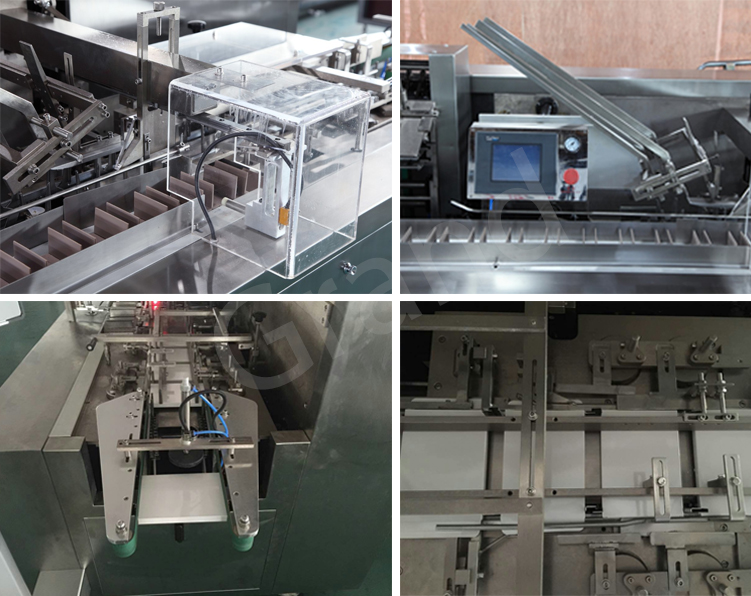

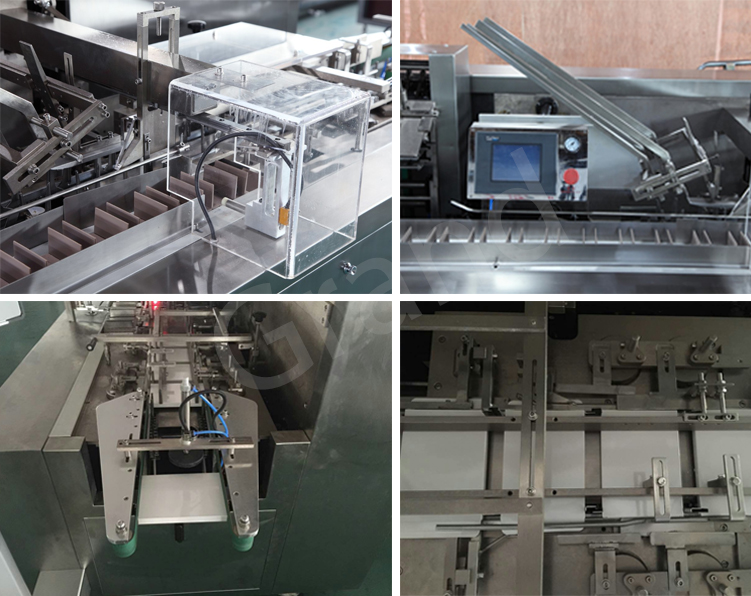

Description

The machine is innovated and designed in strict accordance with pharmaceutical requirements of GMP. Its housing is made of stainless steel of high quality. Besides, overload protection and emergency stop are all designed into the transmission part. What’s more, HMI is applied in control system to secure the operator.

Main technical features

1. The machine will not suck instructions without product and not suck cartons without instruction;

2. The machine will idle and not push products when there is no product or the product is not supplied as set. It will operate automatically after its returning to normal supply of products, while it stops when cartons are not supplied as set.

3. The machine stops without cartons or continuously without instructions for many times.

4. Product specifications can be changed easily and conveniently.

5. Main transmission system has overload protection device.

6. The machine can display cartoning speed, and count automatically.

Main technical parameters

Items | Parameters |

Cartoning speed | 70-100 cartons/min |

Carton | Quality requirement | 250-350g/m2 (depending on the carton size) |

Dimensions (L*W*H) | (70-180)*(35-85)*(14-50)mm |

Instructions | Quality requirement | 60-70g/m2 |

Unfolded size (L*W) | (80-250)*(90-170)mm |

Folds | 1-4 fold(s) |

Compressed air | Operation pressure | ≥0.6MPa |

Air consumption | 120-160L/min |

Power supply | 220V, 50Hz or 380V, 50Hz(can be customized) |

Main motor power | 0.75KW |

Overall dimensions (L*W*H) | 3100*1100*1550mm |

Net weight | About 1400Kg |

Sample Display

Production Process

Company Information

ABOUT US

Our Service

1.We will dispatch engineers to your site for machine installation and commissioning, and also do the training for your technicians.

2.We makes guarantee of the machine for 12 (twelve) months. During this Warranty period, the seller will provide free spare parts that cause by the machine’s quality within 10 days by fast courier upon receipt of buyer’s notice.(we will also provide one set of spare parts /wear &tear parts to customer along with the shipment of the machine.

3.We warmly welcome the suggestions from customer to make us grow better and produce better machine along with providing better service to customer, and create more value for customer.

4.Before placing the order or before shipping, welcome to our factory to take a visit to inspect our machine. we will pick you up in the airport or train station and arrange your following schedule in our city to bring you a nice journey during this visit.

English

English