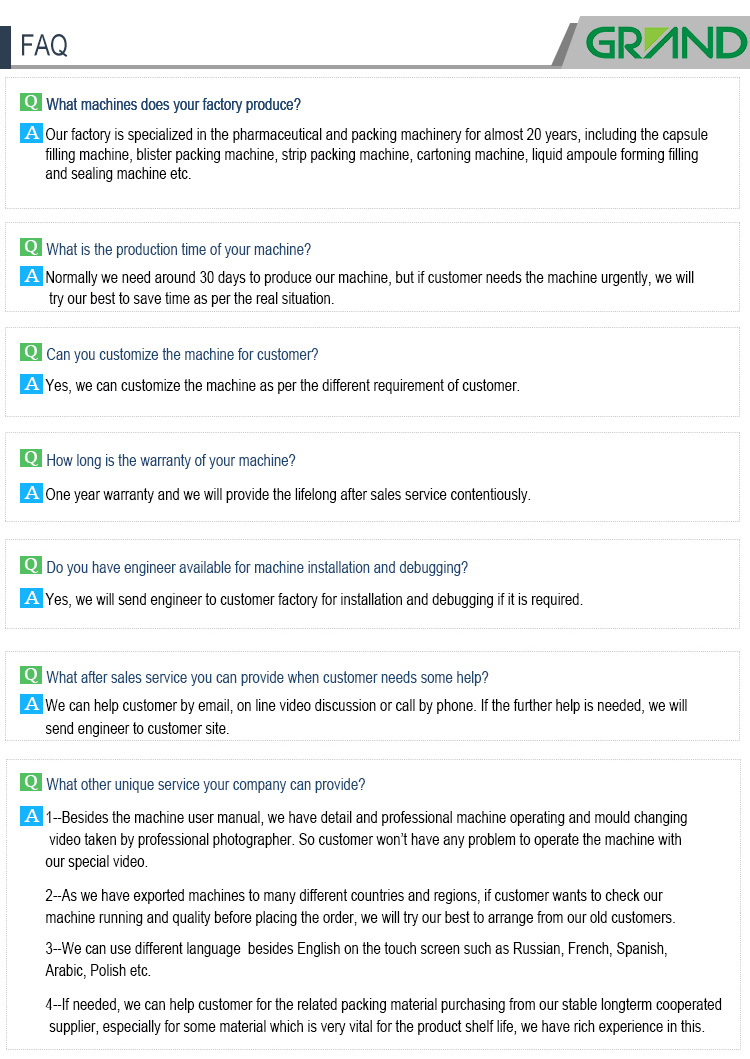

1. Overview

This is a dynamic and multi functional vertical cartoning machine, which can be used to carton and box packing for various kinds of products. The product, depends on its shape and feature, it can be automatically placed into the box or we can put it into the box manually. Therefore, sometimes it can be taken as a semi automatic top feeding cartoning machine. It can be used to carton the car bulb, LED bulb, switch socket, filter, snacks, 502 glue, non-tray oral liquids, cosmetics,bottle, tube, multi pieces of sachet and so on in pharmaceutical industry, food industry, cosmetic industry, electronics etc.

2. Features

1) It is specially designed to carton products in cartons with variable sizes and small output.

2) With low cost and small area, it is suitable for cartons with various sizes. It is also a vertical cartoning machine with multiple functions. Time for mould change is pretty short.

3) 304 stainless steel cover.

4) Advanced PLC Control System, together with 5.7” Colorful Touch Screen Control Panel, can help set and change the parameters easily.

3. Options

Leaflet inserting, hot glue sealing, hot ribbon coding

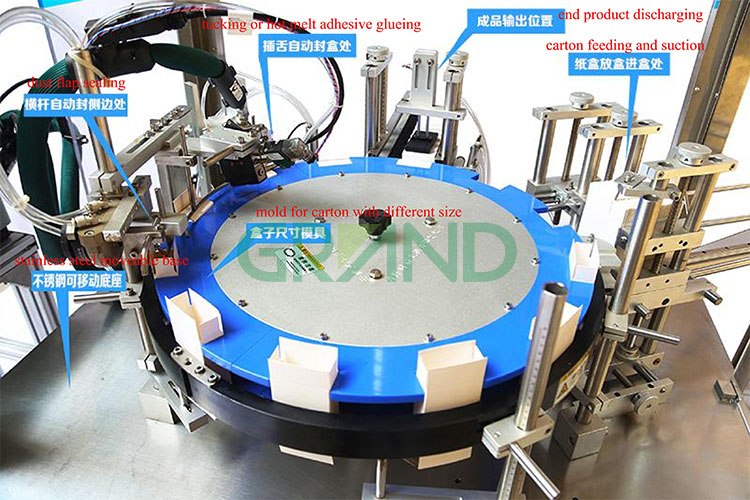

4. Cartoning process

Suck cartons into the star-type wheel---Fold lower small flap of the carton---Fold the lower big flap---Tuck the lower big flap---products feeding into the box (manually or automatically)---Fold upper small flap of carton---Fold the upper big flap---Tuck the upper big flap---Discharge end products

5. Parameters

Model | DJ-50 |

Production speed: | 20-50 cartons/min |

Max. carton size | 200*80*80mm |

Min. carton size | 60*20*20 mm |

Paper quality of carton | 250-350g/m3 |

Motor power | 1/4HP, 15:1, 1.5KW/H |

Power supply | 220V, 50/60HZ, single phase(can be customized) |

Machine noise | ≤80dB |

Gas source | 0.5-0.8 Mpa |

Compress air consumption | 260L/min |

Machine measurement: | 1100*1500*1700 mm (L*W*H) |

Machine weight | 450Kg |

6. Equipment details figures

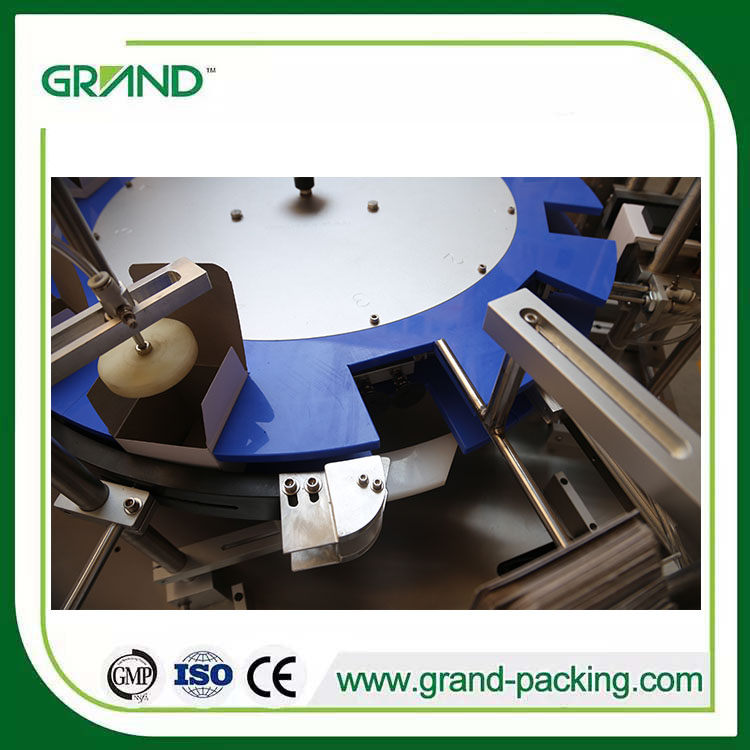

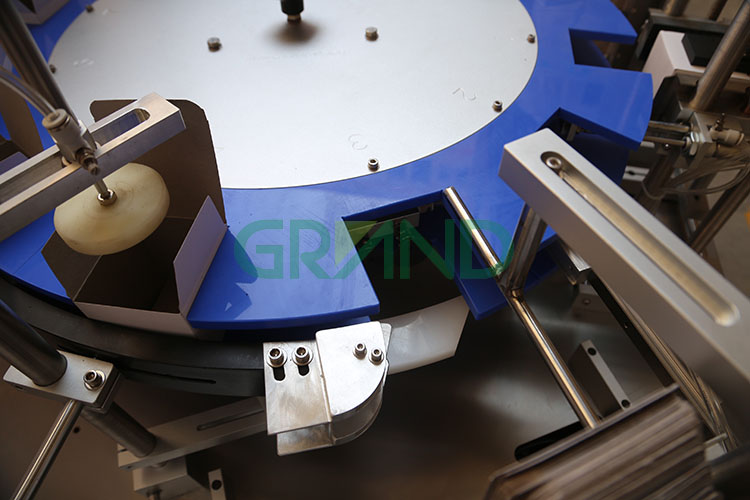

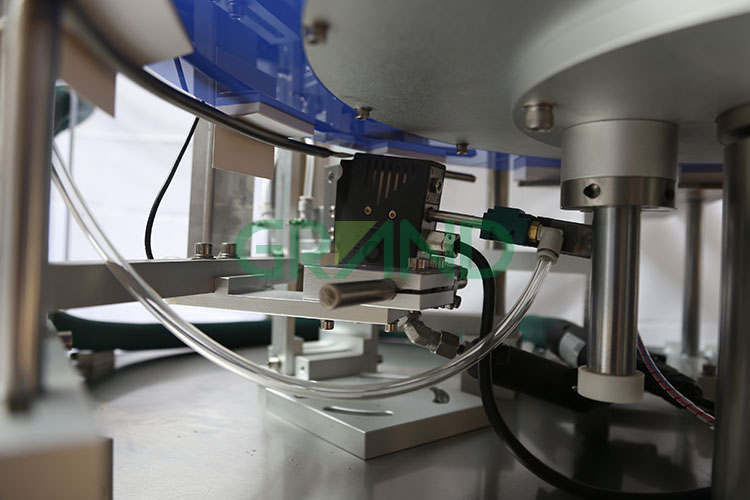

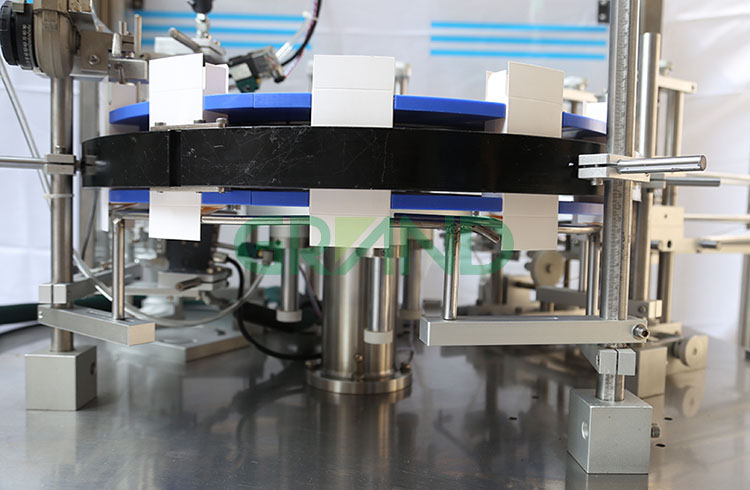

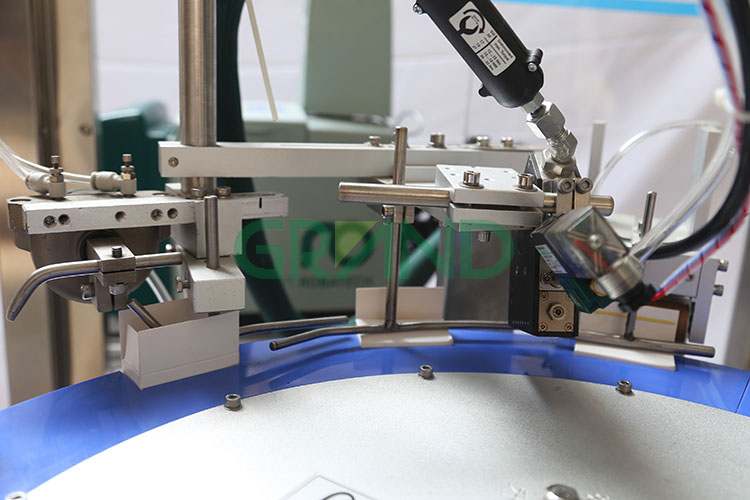

Front view of manual product feeding station

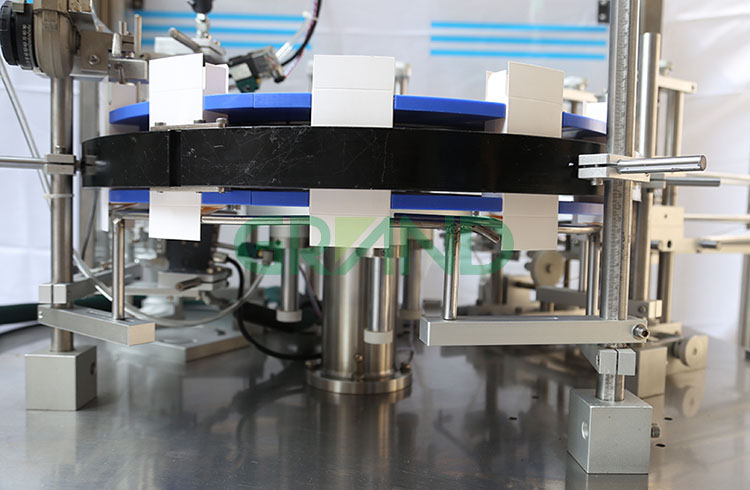

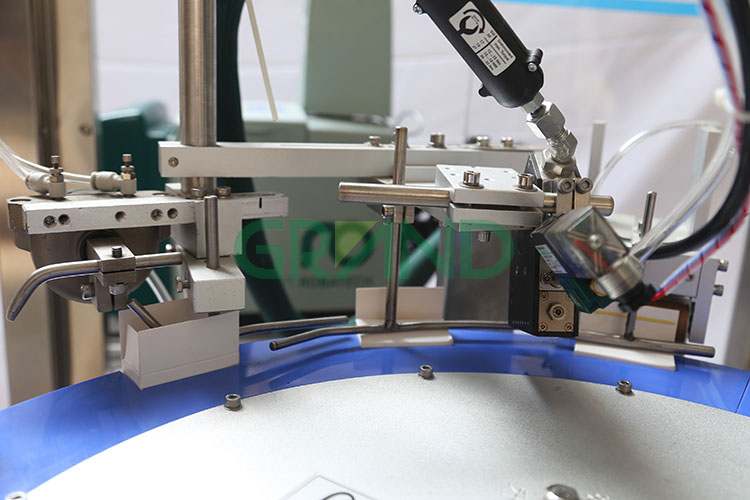

Top view of manual product feeding station

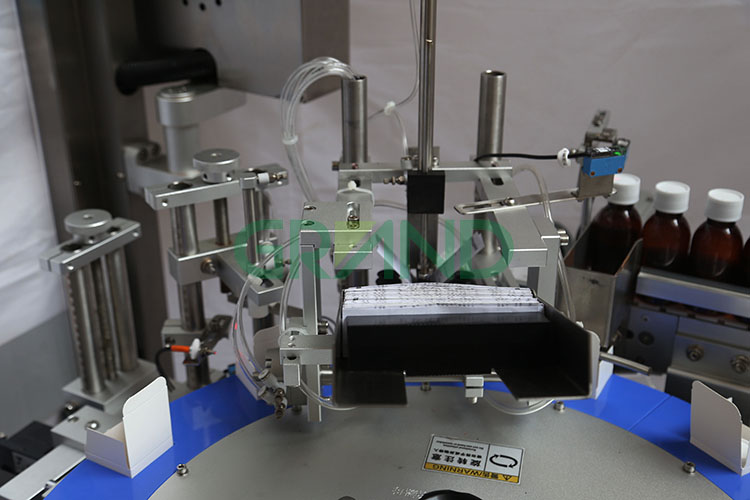

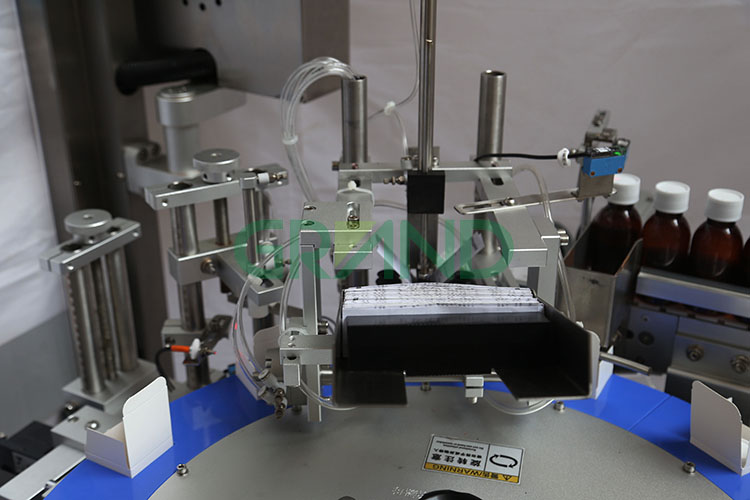

Automatic product feeding into box( for product suitable for auto feeding)

Pre-folded leaflet feeding into the box

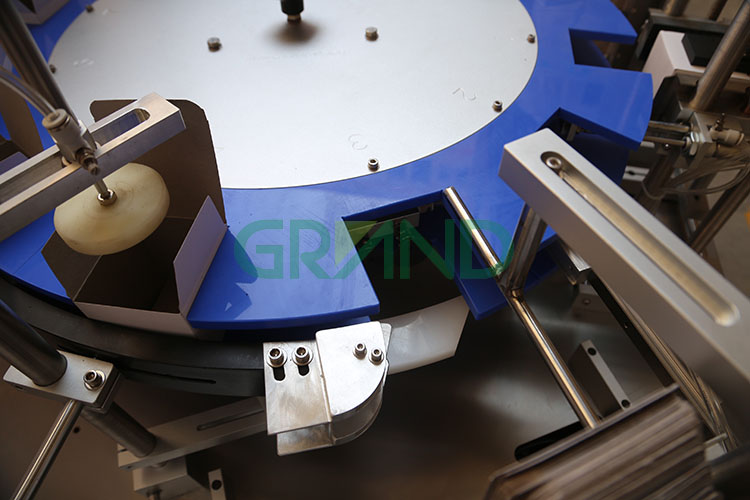

Carton opening station

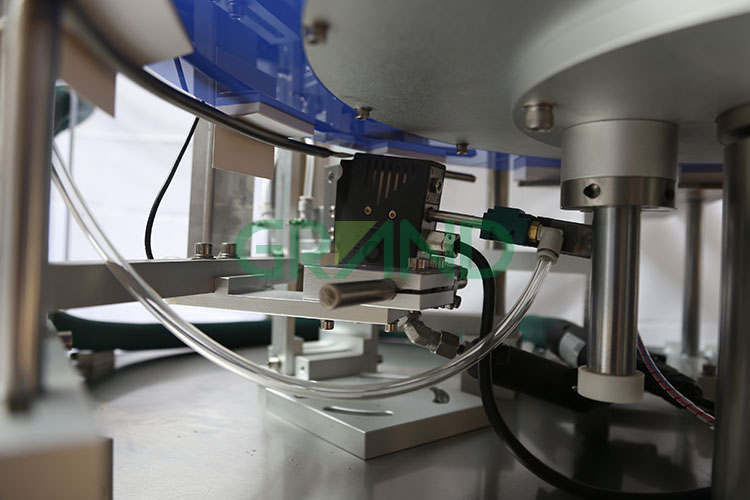

Carton bottom gluing station

Carton top gluing station( It can be tuck in closing)

Carton discharging station

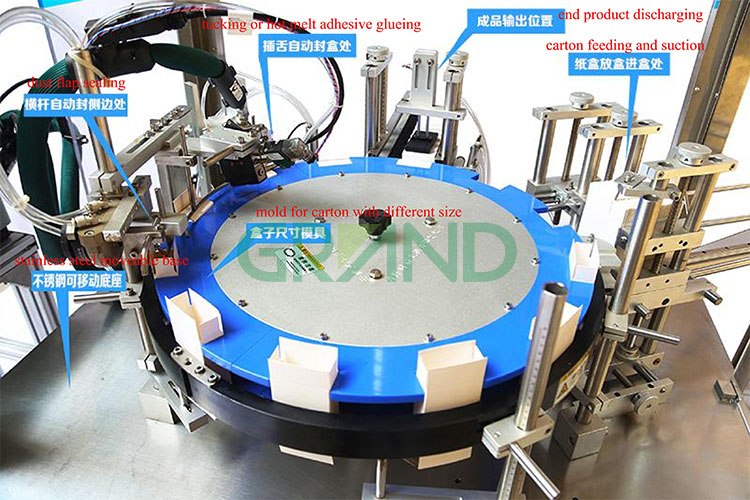

All stations display

Some samples

Our Services

Service 3: We will dispatch engineers to your site for machine installation and commissioning, and also do the training for your technicians.

Service 4: We makes guarantee of the machine for 12 (twelve) months. During this Warranty period, the seller will provide free spare parts that cause by the machine’s quality within 10 days by fast courier upon receipt of buyer’s notice.(we will also provide one set of spare parts /wear &tear parts to customer along with the shipment of the machine.

Service 5: We warmly welcome the suggestions from customer to make us grow better and produce better machine along with providing better service to customer, and create more value for customer.

Service 6: Before placing the order or before shipping, welcome to our factory to take a visit to inspect our machine. we will pick you up in the airport or train station and arrange your following schedule in our city to bring you a nice journey during this visit.

Company Information

ABOUT US

Hunan Grand Packing Machinery Co.,Ltd is specialized in the pharmaceutical and packing machinery for more than 10 years, such as plastic ampoule forming filling and sealing machine, capsule filling machine, blister packing machine, strip packaging machine, cartoning machine etc. We have provided services and machines to many different countries and regions in the whole world, such as Indonesia, Thailand, Malaysia, Philippines, New Zealand, Korea,the Middle East area, Poland, Belgium, France, UK, Greece, Italy, Turkey, USA, central and south America such as Trinidad and Tobago,Mexico, Brazil, Russia, Ukraine, UZ, Tunisia, Algeria, Morroco etc. And we always gain the good reputation from customer both from the machine quality and after sales service.

customer visit at our factory and our visit to customer

Our factory

We are cooperating with various kinds of factories and companies in different fields, including pharmaceutical factory, food factory, supplement factory, agrochemical factory such as for pesticide, fertilizer, personal care product factory, such as for cosmetic product, daily use product, stationery factory, hardware factory etc.

English

English