Machine Brief

This machine is a kind of compact type liquid filling and sealing machine, it is suitable for small batch filling for different product and widely used for filling oral liquid, perfume, liquid , essential oil, olive oil, health care product etc in pharmaceutical, herbal, pesticide, cosmetic, food and supplement area.

Main Features

1.The machine adopts PLC control and stepless altering frequency adjustment.

2.The machine can finish the following 6 working station automatically through the programmer, roller sheet release, PVC/PE forming, filling, press the batch number, back-end crop, slitting

3.The machine adopts the human-machine interface operation, operation is easy and simple

4.The filling head has no leakage, no foam and overflow.

5.The contact parts with the material adopt SUS316L, which completely confirms to the GMP standard.

6.The main pneumatic component and electric parts adopt well-known brand products.

7.Filling system adopts mechanical pump, measuring is precisely and the difference is small. We can also design different pump for different product with various kinds of flow-ability.

8.The machine can be connected with labeling machine to realize full production for filling sealing and labeling.

Machine application

This machine is widely used for the plastic ampoule/bottle forming, filling and sealing for different kinds of honey, butter, food paste such as red curry paste, massaman curry paste,onion paste, ginger paste, garlic paste, umeboshi paste, tamarind paste, turmeric paste, tomato paste, crab paste, chili paste, truffle paste,porcini paste, sesame paste, peanut paste, bean paste, spice paste etc.

The filling volume can be adjusted and we can design any bottle shape for you.

Main technical parameters

| Model | GGS-118 (2 filling heads) | GGS-118 (5filling heads) |

| Max. Forming Depth | 12mm | 12mm |

| Cutting Speed | 0-25 times | 0-25 times |

| Packing Material | PVC/PET combined sheet (thickness:0.2-0.4mm) | PVC/PET combined sheet (thickness:0.2-0.4mm) |

| Filling Volume | 0.5-200ml | 0.5-200ml |

| Power Supply | 4.3kw 220V/380V 50HZ (can be customized) | 7kw 220V/380V 50HZ (can be customized ) |

| Machine Weight | 700kg | 900kg |

| Machine Dimension | 1750×750×1400mm | 2300×850×1500mm |

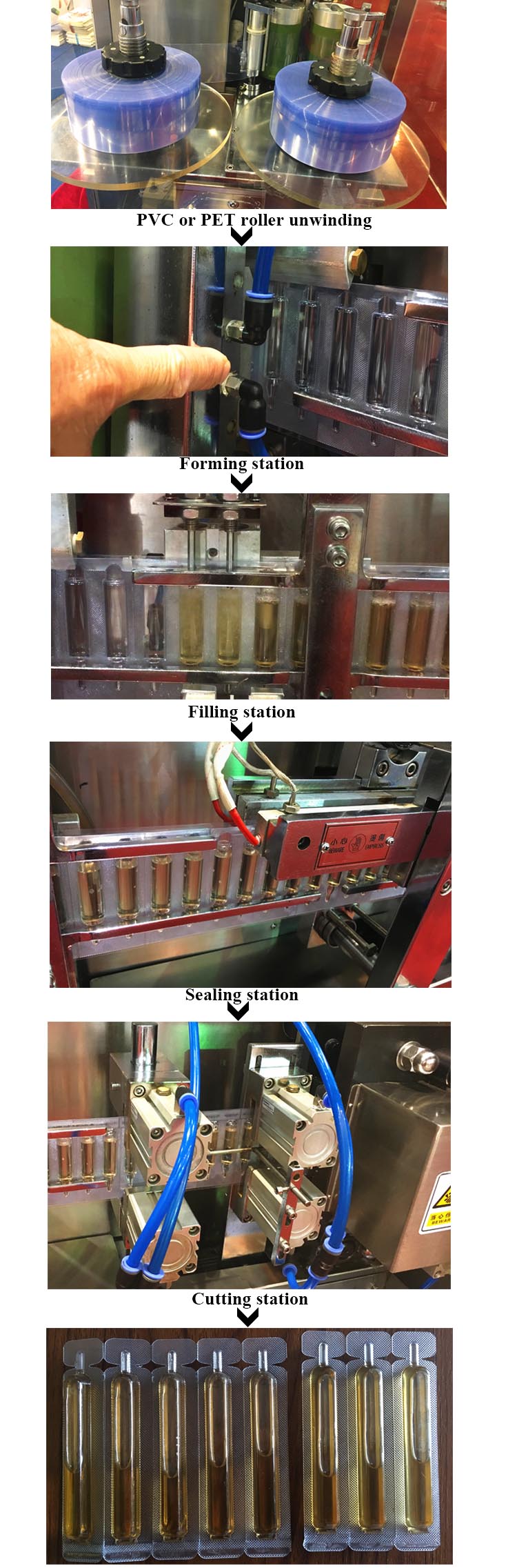

Production Process

Our Services

Service 3: We will dispatch engineers to your site for machine installation and commissioning, and also do the training for your technicians.

Service 4: We makes guarantee of the machine for 12 (twelve) months. During this Warranty period, the seller will provide free spare parts that cause by the machine’s quality within 10 days by fast courier upon receipt of buyer’s notice.(we will also provide one set of spare parts /wear &tear parts to customer along with the shipment of the machine.

Service 5: We warmly welcome the suggestions from customer to make us grow better and produce better machine along with providing better service to customer, and create more value for customer.

Service 6: Before placing the order or before shipping, welcome to our factory to take a visit to inspect our machine. we will pick you up in the airport or train station and arrange your following schedule in our city to bring you a nice journey during this visit.

Company Information

ABOUT US

Hunan Grand Packing Machinery Co.,Ltd is specialized in the pharmaceutical and packing machinery for more than 10 years, such as plastic ampoule forming filling and sealing machine, capsule filling machine, blister packing machine, strip packaging machine, cartoning machine etc. We have provided services and machines to many different countries and regions in the whole world, such as Indonesia, Thailand, Malaysia, Philippines, New Zealand, Korea,the Middle East area, Poland, Belgium, France, UK, Greece, Italy, Turkey, USA, central and south America such as Trinidad and Tobago,Mexico, Brazil, Russia, Ukraine, UZ, Tunisia, Algeria, Morroco etc. And we always gain the good reputation from customer both from the machine quality and after sales service.

customer visit at our factory and our visit to customer

Our factory

We are cooperating with various kinds of factories and companies in different fields, including pharmaceutical factory, food factory, supplement factory, agrochemical factory such as for pesticide, fertilizer, personal care product factroy, such as for cosmetic product, daily use product, stationery factory, hardware factory etc.

English

English