Full-automatic Suppository Production Line is suitable for the production of special shape such as bullet head, torped shape ,oval and duck bill, to meet the production of your suppository.(according to the specifications of your specifications).

Production process

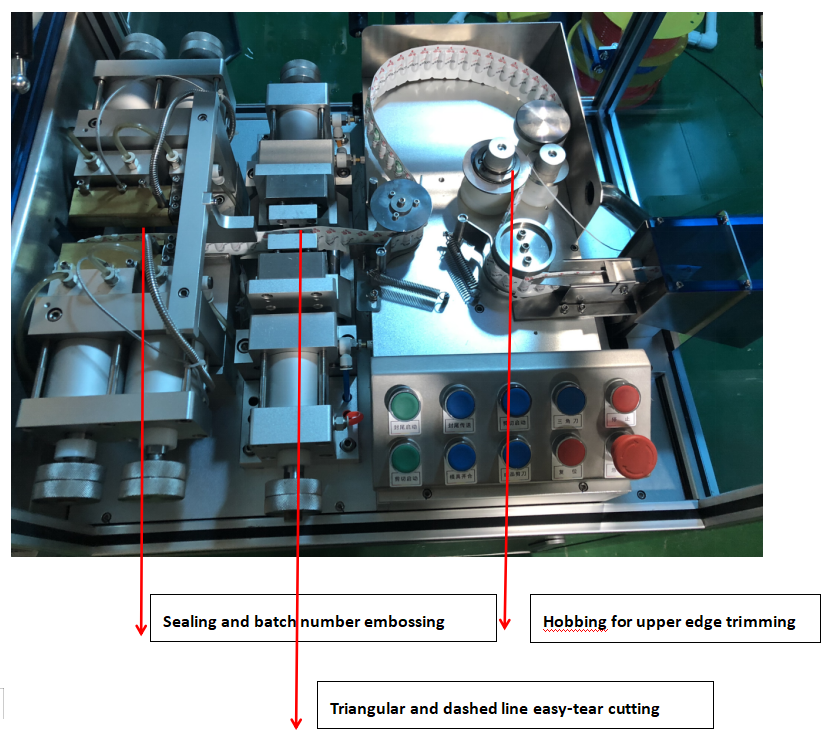

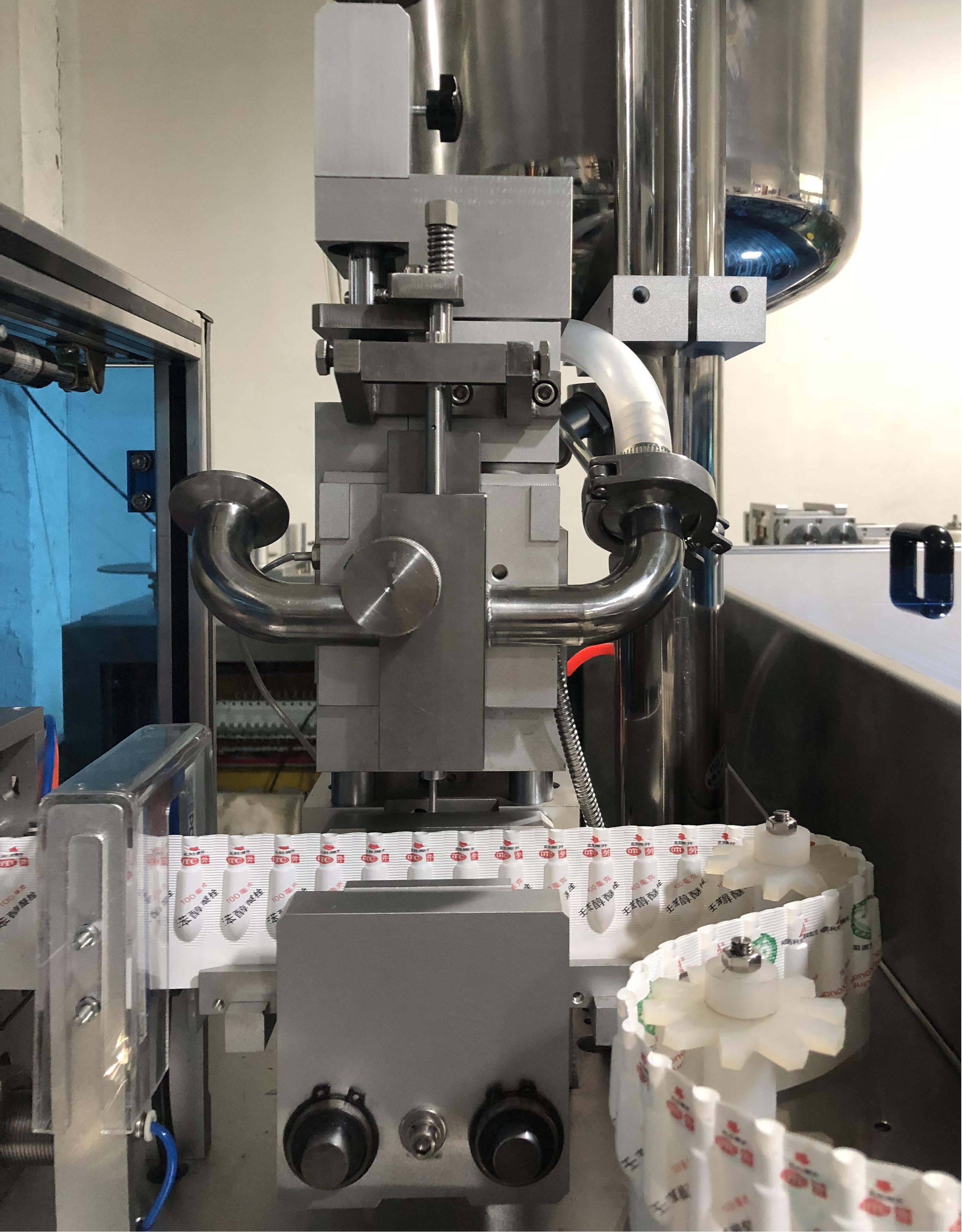

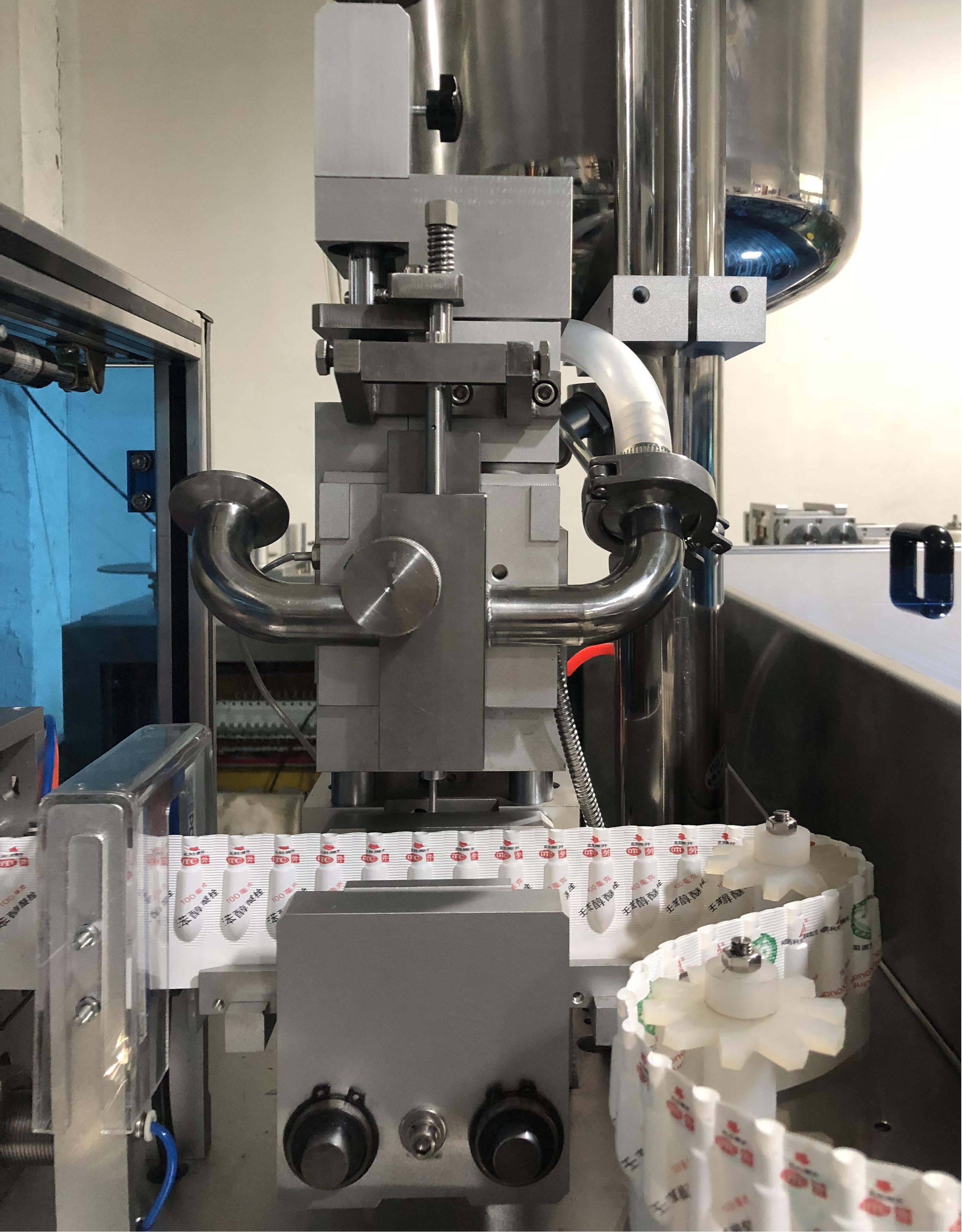

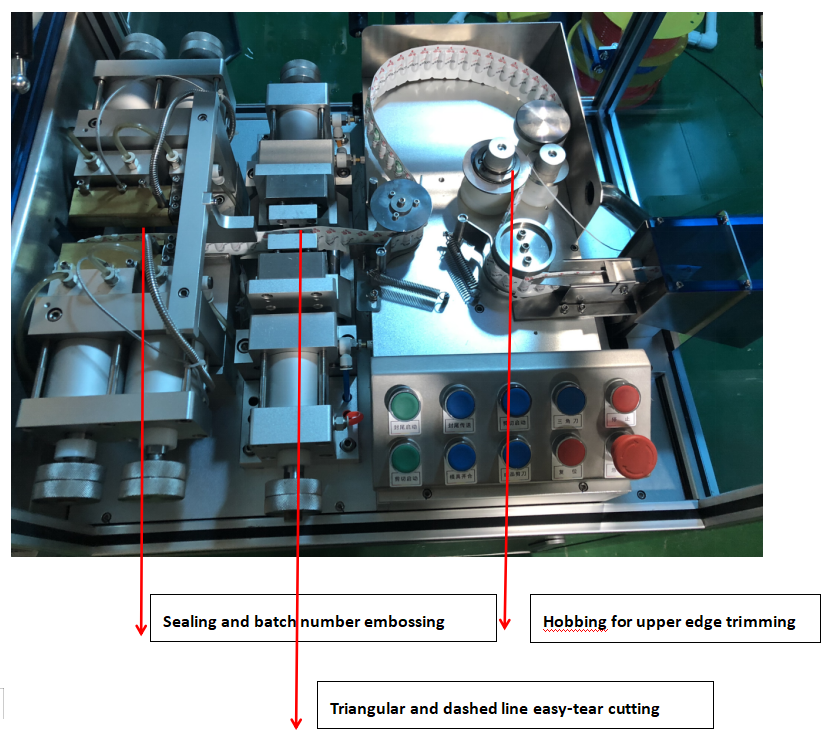

Automatic shell forming for medicine filling >> Reciprocating cooling and shaping (liquid to solid) >> Continuous sealing and batch number embossing >> Finished product convoying for punching

Technical parameter

| model | GSJ-1B | GSJ-1L | GSJ-3L | GSJ-7L |

| Output | 1000-1500 pcs/h | 1000—2000 pcs/h | 3000—4000 pcs/h | 9000-12000pcs/h |

| Filling Valve Head | 1 filling head | 3 filling heads | 7 filling heads |

| single dosage | 0.5—3.5ml | 0.5—5ml | 0.5—5ml | 0.5—5ml |

| Packaging Film | Prefabricated pipe | PVC\PE\PVC (thickness0.15mm) |

| Each distance of suppository | 17.4mm |

| Stirring tank capacity | 20L | 20L | 30L | 70L |

| Adopt forming shapes | Prefabricated pipe | Bullet, torpedo and duck shapes and other shapes |

| Adapt Material | Synthetic fatty acid glycerol, glycerin gelatin, polyethylene glycol etc |

| Air pressure | ≥0.6Mpa |

| Air consumption/min | 0.7m3/min | 1.2m3 | 1.3m3 | 1.5m3 |

| Water consumption/h | 50kg (recycling) |

| total power | 3KW | 4KW | 5KW | 7.5KW |

| Dosage allowed | <±2% |

| Working voltage | 3P 380V 50 HZ |

| Machine Weight | 550kg | 500kg | 1000kg | 2T |

| Overall dimensions(mm) | 2500*969*1819 | 2300*1200*1800 | 3600*1400*1800 | 5500*2000*2100 |

Equipment Advantages

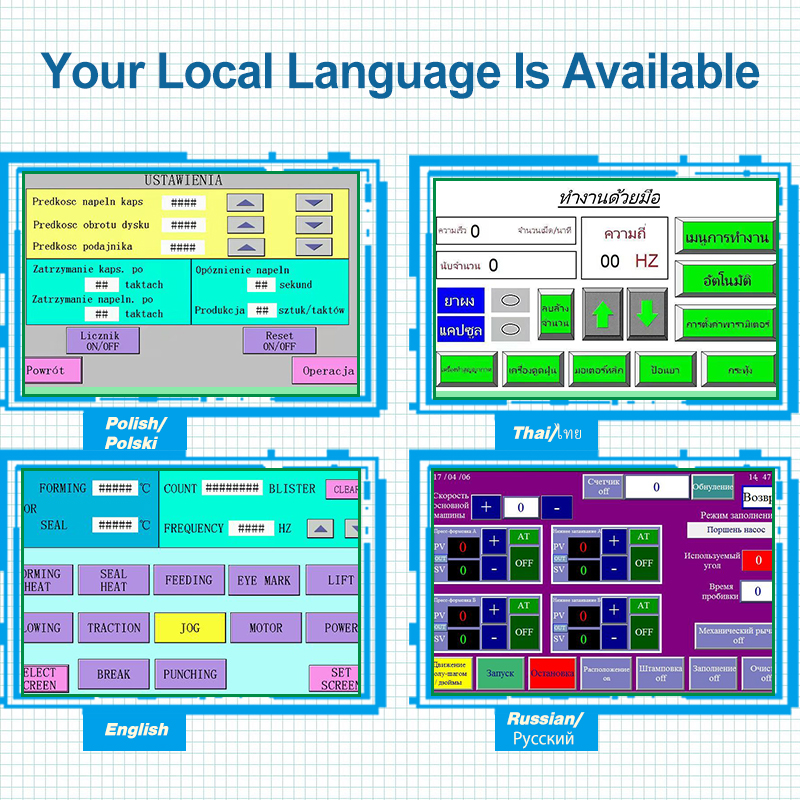

1. PLC inspection function: through PLC online monitoring function can inspect automatic running fault and alarm as the same time show the reason of running fault its convenient operator to remove the fault timely.

2.The filling part with removing static electricity system

Note: before forming shell reach filling place if without this device because trace drug filling and close shell top position will along the shell wall climb up a small hill under the static electricity function reach suppository sealing part will affect the quality of behind the seal.

3. Stirring barrel speed adjustable system

Note: because of the drug material different and the viscosity different maybe the same stirring result can not mix drug uniform before filling so that affect finished suppository products drug content.

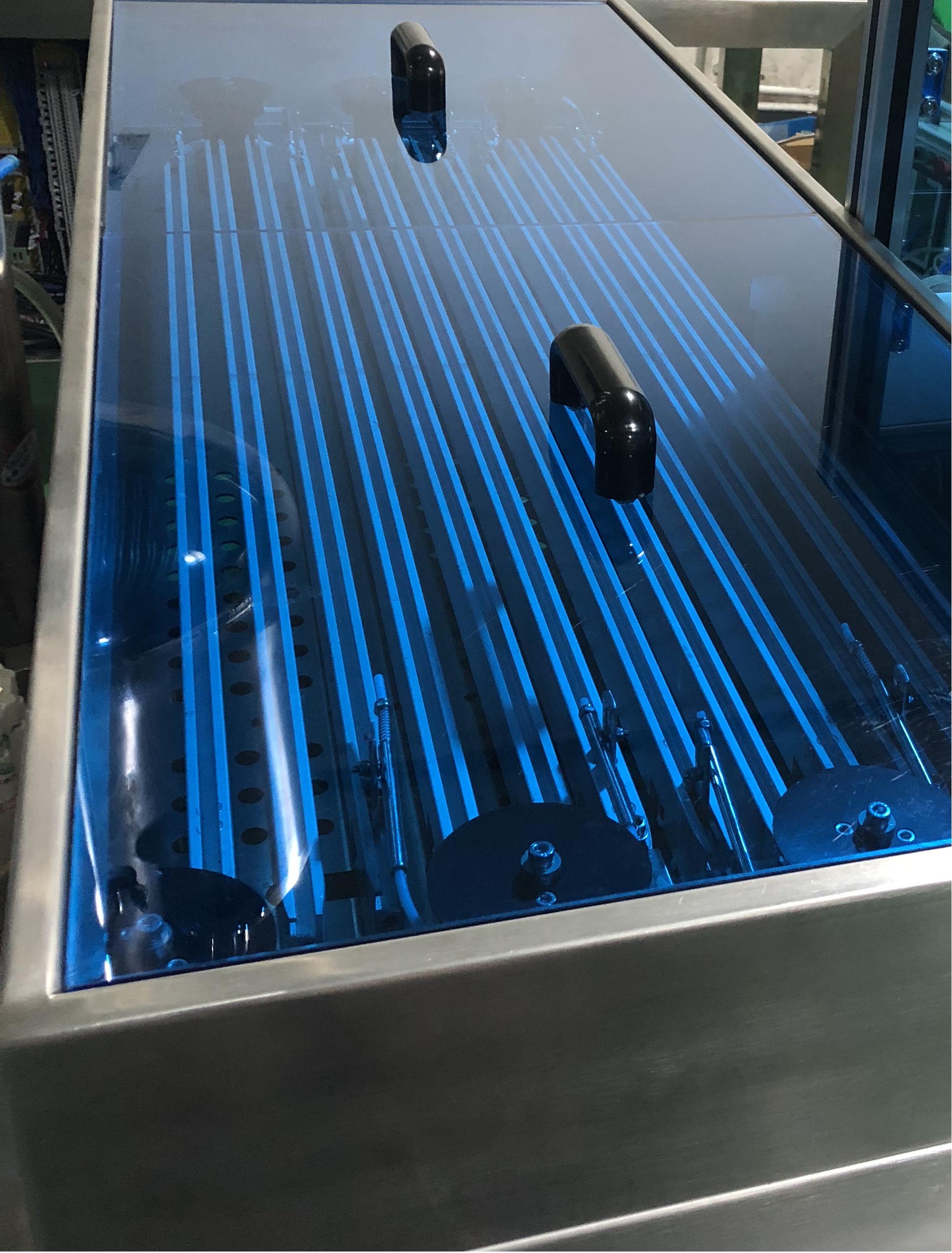

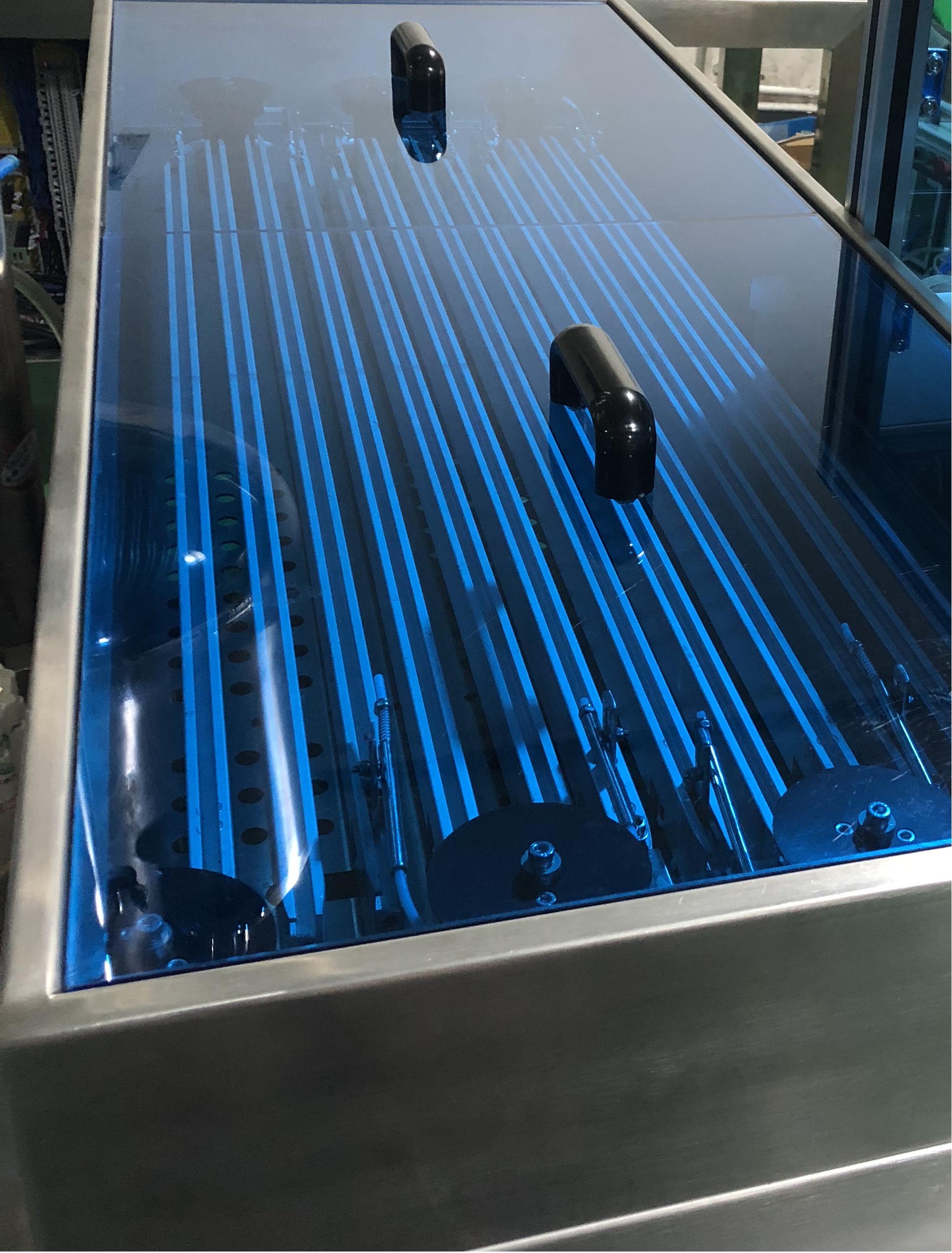

4. Cooling speed adjustable system

Note: because of different drug different components maybe need different cooling speed; when the cooling speed too slow will reduce the whole machine production efficiency. If the cooling speed too high maybe due to drug suddenly drop temperature then fracture therefore cooling speed need adjustable.

5. Cutting granules quantity can be adjustable system

Note: according to customer s requirement can convenient set up finished products granules as 4/5/6/7/8/9/10 granules.suppository punishment.

Manufacturing Principle:

Full-automatic Suppository Production Line is welded flat, with no edge, slag and splash.The whole machine is treated with reliable rust.The surface of the equipment is 304 stainless steel.It is smooth and easy to clean.Components, accessories and motors and so on should adopt domestic and foreign premium brands.

Ensure the appearance of the equipment and smooth operation.

Safety of Equipment:

Full-automatic Suppository Production Line has sufficient safety equipment to guarantee that operators will not be harmed in the operation. The equipment running noise is less than 70 dB (A).

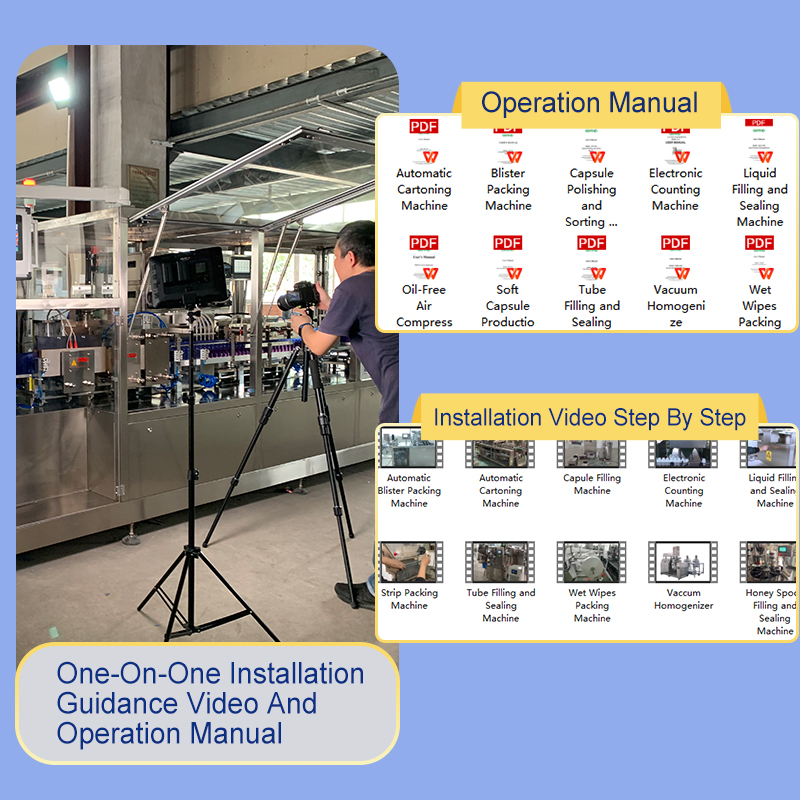

Our Services

Service 3: We will dispatch engineers to your site for machine installation and commissioning, and also do the training for your technicians.

Service 4: We makes guarantee of the machine for 12 (twelve) months. During this Warranty period, the seller will provide free spare parts that cause by the machine’s quality within 10 days by fast courier upon receipt of buyer’s notice.(we will also provide one set of spare parts /wear &tear parts to customer along with the shipment of the machine.

Service 5: We warmly welcome the suggestions from customer to make us grow better and produce better machine along with providing better service to customer, and create more value for customer.

Service 6: Before placing the order or before shipping, welcome to our factory to take a visit to inspect our machine. we will pick you up in the airport or train station and arrange your following schedule in our city to bring you a nice journey during this visit.

Company Information

ABOUT US

Hunan Grand Packing Machinery Co.,Ltd is specialized in the pharmaceutical and packing machinery for more than 10 years, such as plastic ampoule forming filling and sealing machine, capsule filling machine, blister packing machine, strip packaging machine, cartoning machine etc. We have provided services and machines to many different countries and regions in the whole world, such as Indonesia, Thailand, Malaysia, Philippines, New Zealand, Korea,the Middle East area, Poland, Belgium, France, UK, Greece, Italy, Turkey, USA, central and south America such as Trinidad and Tobago,Mexico, Brazil, Russia, Ukraine, UZ, Tunisia, Algeria, Morroco etc. And we always gain the good reputation from customer both from the machine quality and after sales service.

customer visit at our factory and our visit to customer

Our factory

We are cooperating with various kinds of factories and companies in different fields, including pharmaceutical factory, food factory, supplement factory, agrochemical factory such as for pesticide, fertilizer, personal care product factory, such as for cosmetic product, daily use product, stationery factory, hardware factory etc.

English

English