1. Application

This mono dosis plastic bottle forming filling and sealing machine is suitable for the unit mono dose dosage of oral liquid medicine, beverage, health care product, milk product, food, cosmetic, perfume, pesticide, liquid fertilizer, syrup, fruit paste,jam etc. It can finish the following working process including the following:

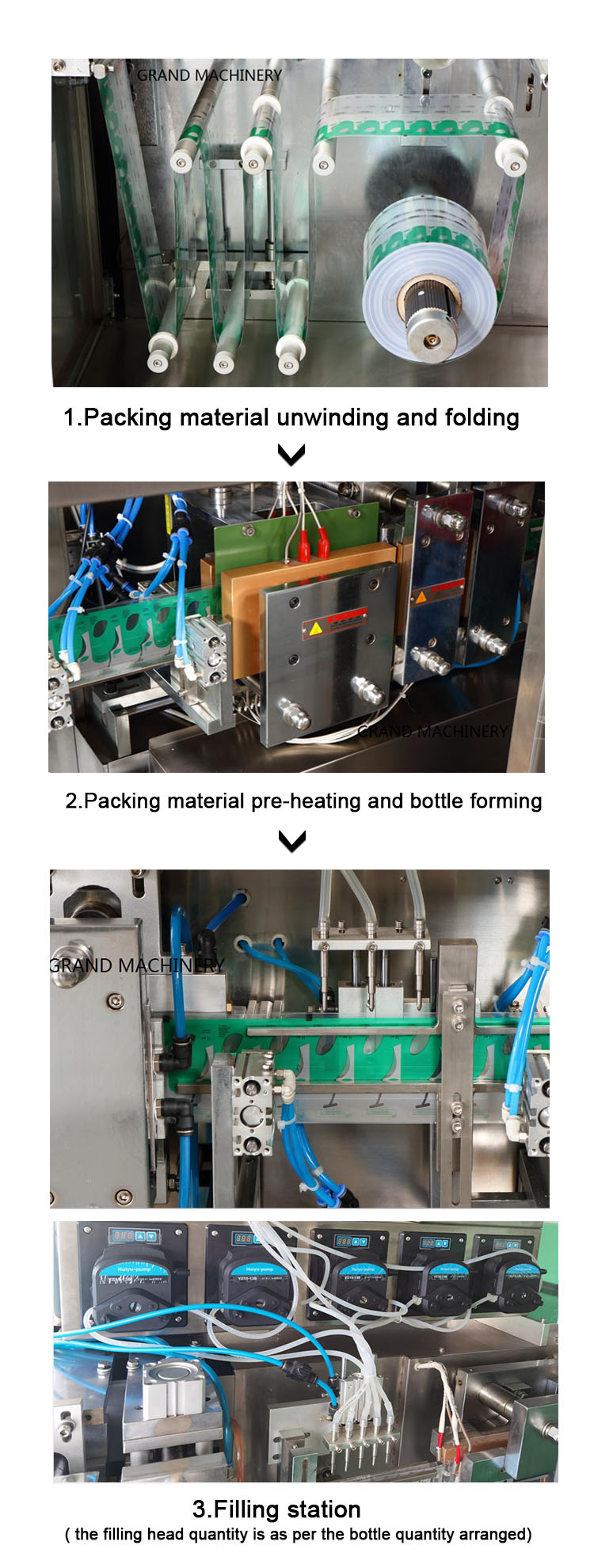

Packing film unwinding--folding--bottle/ampoule forming--product filling--sealing--final product output. We can also add the extra printing and letter or logo engraving function on the machine.

This is a newly developed equipment based on GGS-240P5, with the special features of easy to be transported. The packing material unwinding part can be separated from the machine main part, and the machine main part is also shorter than the old model GGS-240 P5. So it is easy to be moved when in transportation or when place changed. And because the size is smaller than the old model, the room is saved. What's more, extra two more Servo motors are adopted, so the bottle quantity can be set in the touch screen as customer requires, no matter 1pc, 2pcs, 3pcs or 4pcs......

2. Features

1) The machine adopts HC high-speed and high-accuracy motion controller, stepless frequency control of speed and servo motor to control packing film pulling;

2) HMI allows simple operation;

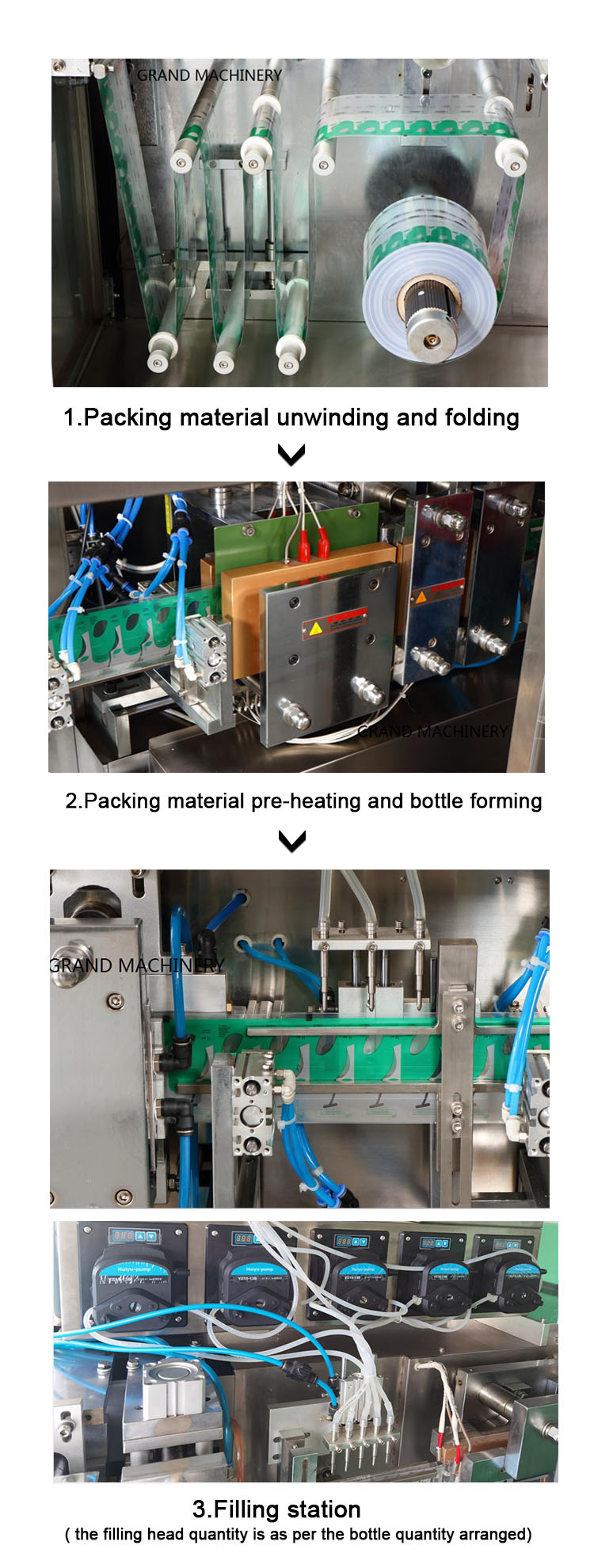

3) The packing film can be fed and cut automatically and photoelectric eye mark tracking system makes sure high products’ quality;

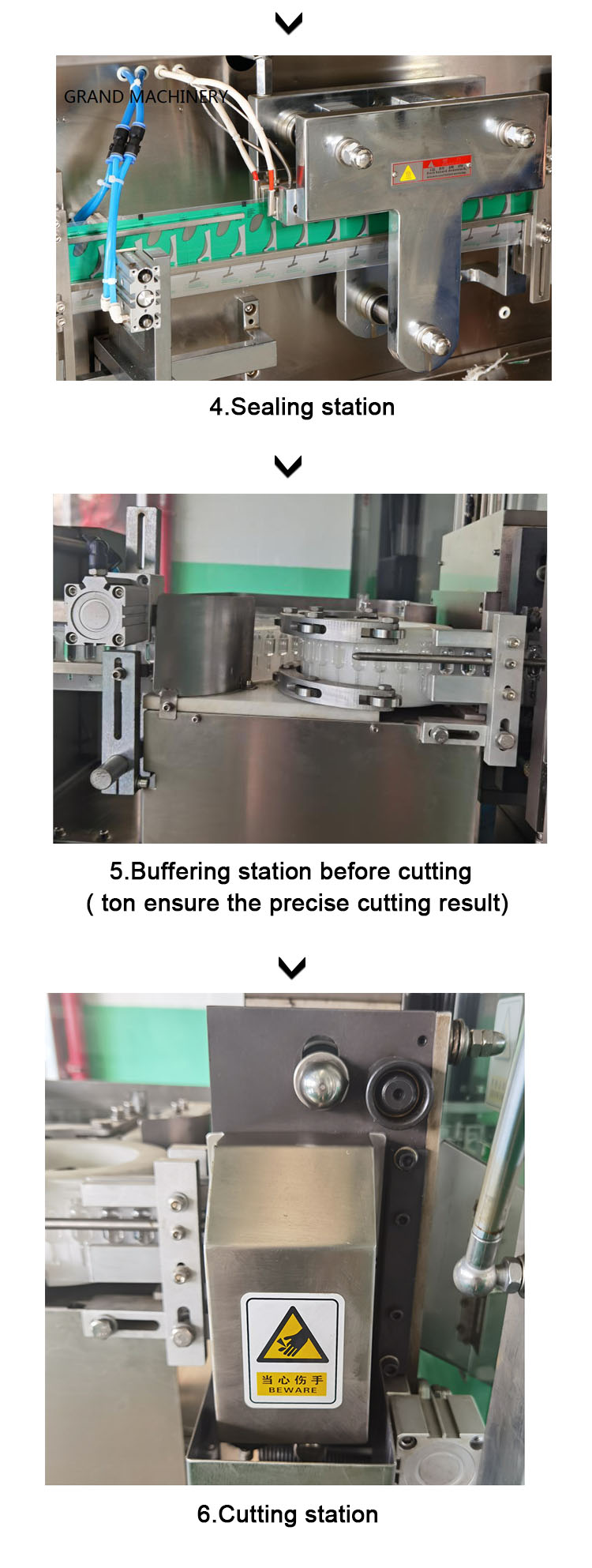

4) The material is pumped by peristaltic pump, mechanical pump or piston pump for convenient adjustment;

5) The filling station features high filling accuracy, no leak, no foam and no overflow;

6) Parts contacting the material are made of SS316 and the outer cover made of SS304, which meets the GMP standards;

7) The bottle bottom is flat so that the bottles can be upright;

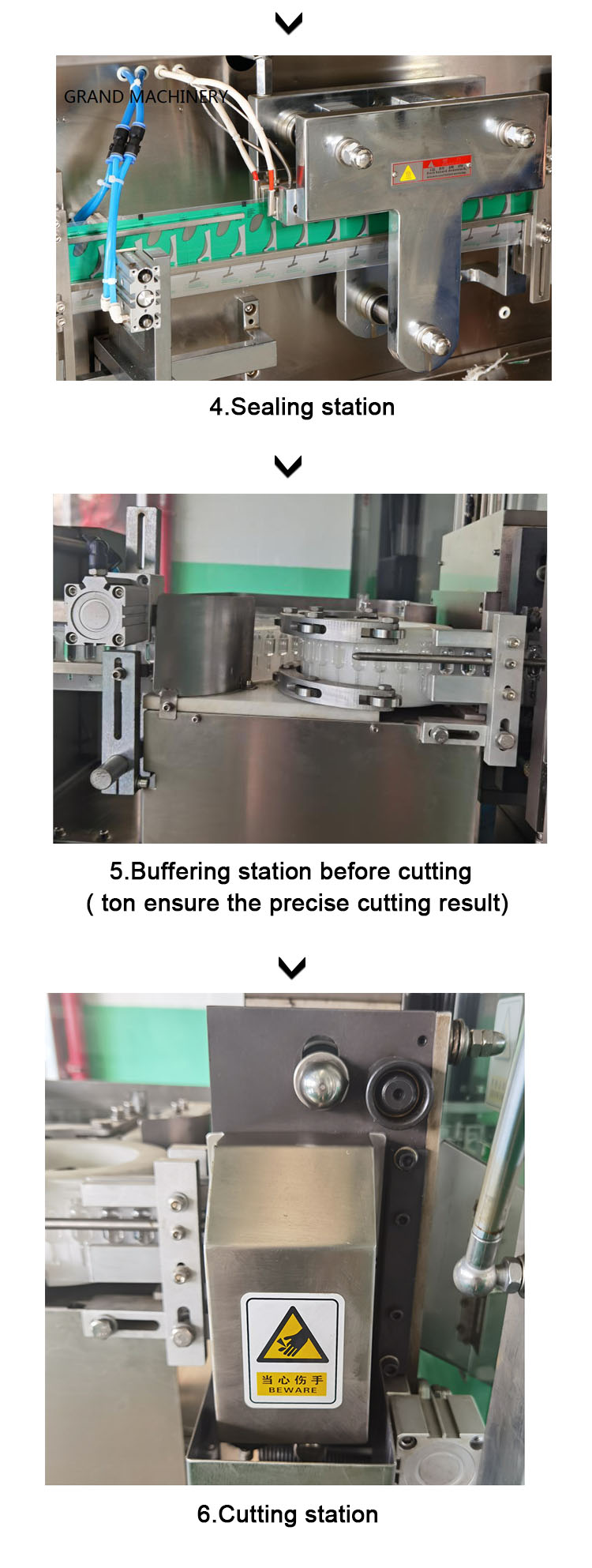

8) The cutter is controlled by a pair of servo motors to punch bottles in any number.

3. Main technical parameters

Model | GGS-240P5 A |

Max. forming depth | 12mm |

Forming frequency | 0-25 times |

Packing film | PVC/PE, PET/PE (0.2-0.4)*140mm |

Filling volume | 1-100ml( can be customized to fill up to 200ml) |

Total power | 7KW |

Powder supply | 380V/50Hz |

Machine weight | 1000Kg |

Overall dimensions (L*W*H) | 3380x950x1800 (mm) |

Dimension of the main split part | 2500x950x1800(mm) |

Production Process

Sample Display

Our Services

Service 3: We will dispatch engineers to your site for machine installation and commissioning, and also do the training for your technicians.

Service 4: We makes guarantee of the machine for 12 (twelve) months. During this Warranty period, the seller will provide free spare parts that cause by the machine’s quality within 10 days by fast courier upon receipt of buyer’s notice.(we will also provide one set of spare parts /wear &tear parts to customer along with the shipment of the machine.

Service 5: We warmly welcome the suggestions from customer to make us grow better and produce better machine along with providing better service to customer, and create more value for customer.

Service 6: Before placing the order or before shipping, welcome to our factory to take a visit to inspect our machine. we will pick you up in the airport or train station and arrange your following schedule in our city to bring you a nice journey during this visit.

Company Information

ABOUT US

Hunan Grand Packing Machinery Co.,Ltd is specialized in the pharmaceutical and packing machinery for more than 10 years, such as plastic ampoule forming filling and sealing machine, capsule filling machine, blister packing machine, strip packaging machine, cartoning machine etc. We have provided services and machines to many different countries and regions in the whole world, such as Indonesia, Thailand, Malaysia, Philippines, New Zealand, Korea,the Middle East area, Poland, Belgium, France, UK, Greece, Italy, Turkey, USA, central and south America such as Trinidad and Tobago,Mexico, Brazil, Russia, Ukraine, UZ, Tunisia, Algeria, Morroco etc. And we always gain the good reputation from customer both from the machine quality and after sales service.

customer visit at our factory and our visit to customer

Our factory

We are cooperating with various kinds of factories and companies in different fields, including pharmaceutical factory, food factory, supplement factory, agrochemical factory such as for pesticide, fertilizer, personal care product factory, such as for cosmetic product, daily use product, stationery factory, hardware factory etc.

English

English