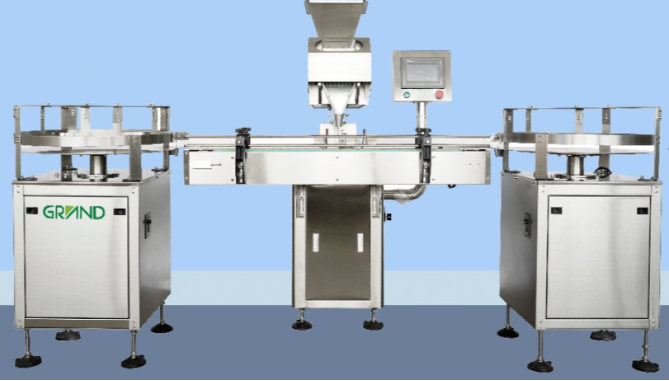

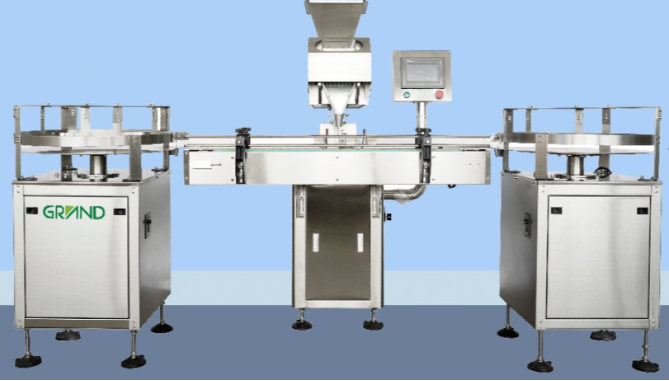

Multi-channel Counting Machine

Last week, we delivered two 8-lane counting machines to France and Slovenia severally. The counting machine is for the next bottle package for soft gelatin capsule, hard capsule, tablet and candy etc after capsule filling, tablet pressing, etc.

After capsule filling or tablet pressing, some producers will choose blister packing machine or double-alu strip packing machine to package the solid products. Quantity of blister is better controlled. Producers don’t need to worry about quantity deviation from the expectation. However, what can they do if they use bottles to pack these solid medicines? In this case, capsule and tablet counting machine can be a better choice to count and bottle solid medicines.

Working Principle

A multi-lane counting machine is an automated system designed for high-speed, accurate counting of small items such as pills, capsules, seeds, hardware components, and so on. Its operation involves the following steps:

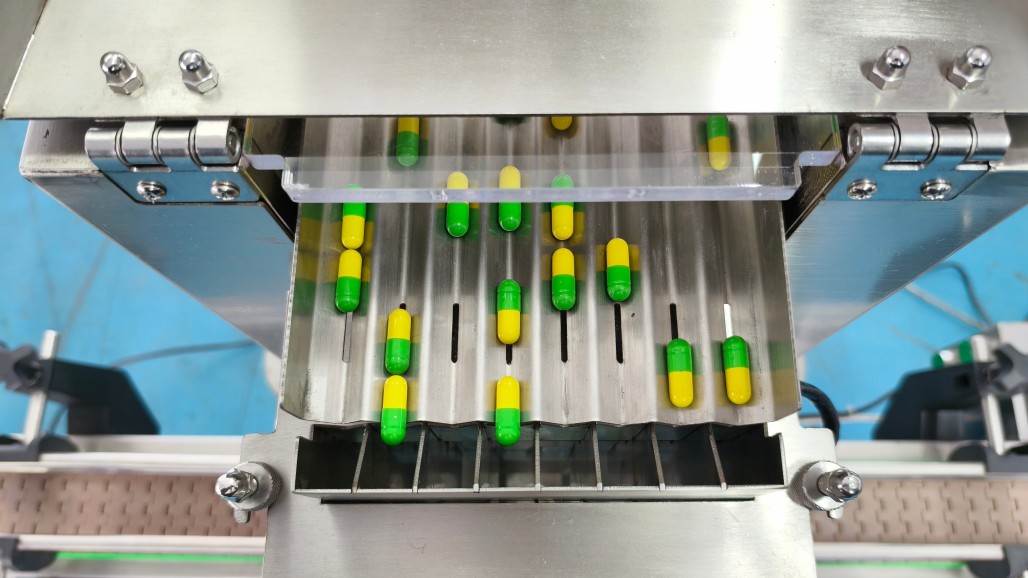

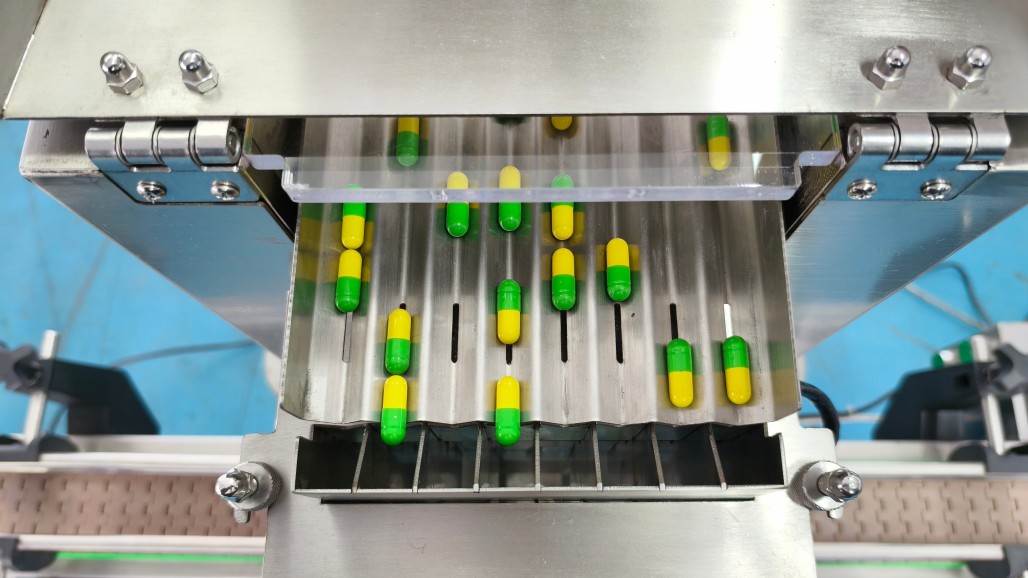

(1) Products feeding and separation via channels

A vibrating feeder or conveyor evenly deliver the items into multiple channels (typically 8~16 channels) for simultaneous counting.

(2) Optical/Infrared/Laser sensing

Each channel adopts a high-precision sensor (e.g., photoelectric, infrared, or laser) that detects the products quantity as they pass.

(3) Parallel Counting & Data Processing

All channels count products independently, and the system aggregates the data in real time. The machine will stop automatically when the preset quantity (e.g., 100 tablets per bottle) is reached.

(4) Discharge & Packaging

After counting, products are delivered into containers (jars,bottles, bags, etc.). The counting machine can be integrated with filling, capping, labeling, and cartoning machines for full automation.

(5) Control & Adjustment

A PLC (Programmable Logic Controller) or industrial PC manages counting speed, vibration frequency, lane settings, etc. Operators can adjust parameters (e.g., sensitivity, batch size) via the touch screen.

(1) Pharmaceutical Industry

Counting tablets, capsules, and softgels for precise packaging (compliant with GMP/FDA standards).

(2) Food & Agriculture

Sorting and packaging candies, nuts, seeds, grains, and beans.

(3) Hardware & Electronics

Counting screws, bolts, bearings, electronic components (e.g., resistors, SMD parts).

(4) Laboratory & Quality Control

Rapid sample counting for research, inventory, or batch verification.

(5) Retail & Consumer Goods

Packaging small items like jewelry, buttons, or toy parts in fixed quantities.

Advantages

✅ High Speed – Processes thousands of items per minute (multi-channel efficiency).

✅ Precision – Advanced sensors and software minimize counting errors.

✅ Versatility – Adjustable lanes accommodate different shapes and sizes.

✅ Automation – Reduces labor costs and human error in packaging.

✅ Data Tracking – Some models store count logs for traceability.

Advanced Features (Optional)

(1) Vision inspection – Cameras detect and reject damaged/misaligned items.

(2) Weight verification – Integrated scales cross-check count accuracy.

(3) Customization – Options include sterile designs (for pharma), anti-static systems (for electronics), or dust-proofing.

Conclusion

Multi-channel counting machine enhances productivity in industries requiring fast, accurate quantification. By automating counting and packaging, the machine improves efficiency, reduces waste, ensures compliance in regulated sectors like pharmaceuticals, food production, supplement and cosmetic, etc.

English

English