We know that the process of blister packaging machines includes steps such as film heating, forming, feeding, sealing, and cutting. Among these, a critical aspect is how to select the appropriate feeding system.

For blister packaging machines,

When the product to be packaged is a liquid, we should choose a pump as the filling device.

When the product is a powder, we opt for screw feeding or measuring cup feeding.

When the product to be packaged is medicine tablets or capsules, what feeding device should we choose?

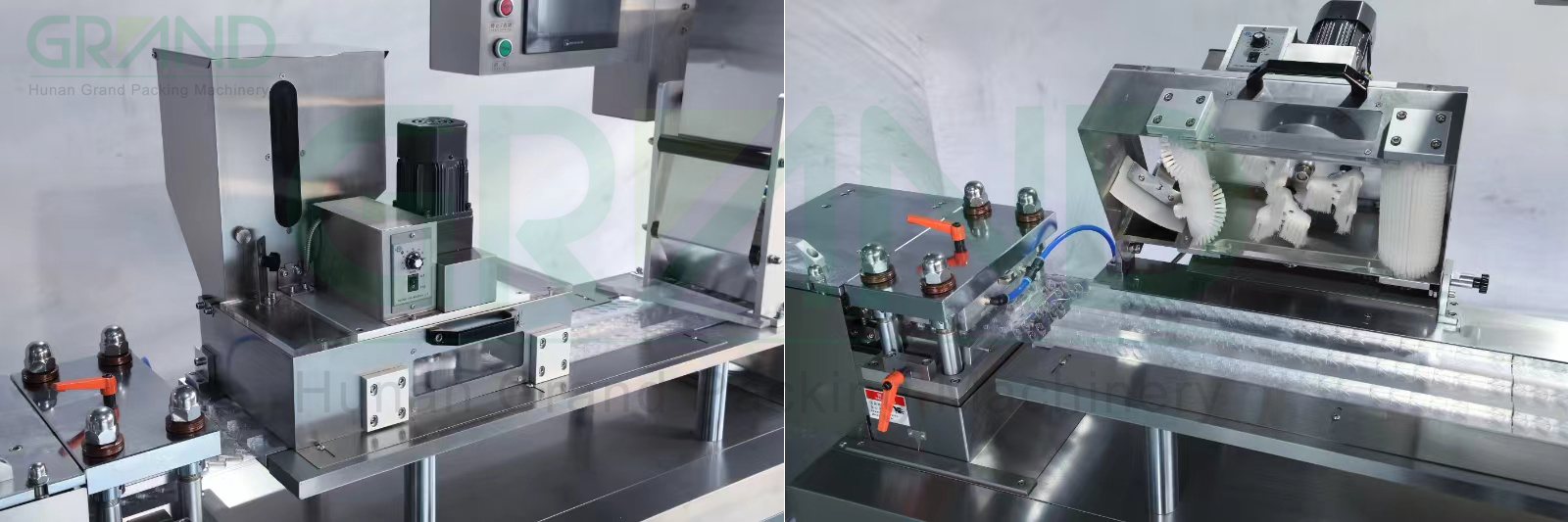

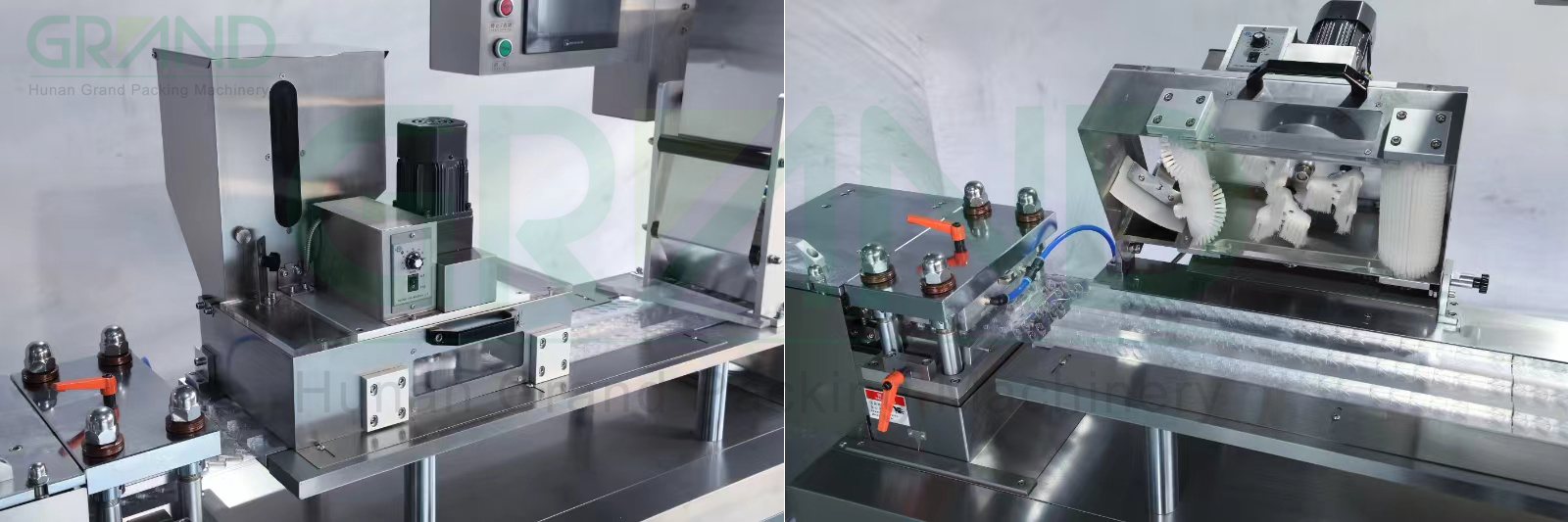

1、Brush Wheel Feeder

The first feeding system we will discuss is the most widely used one—the brush wheel feeder.

The brush box feeder is a feeding system that uses rotating brush sets and silicone scrapers to guide the product into the blister cavities. It can automatically replenish tablets or capsules into the feed box when low material levels are detected. This feeder is suitable for flat-bed blister packaging machines with moderate production speeds. The brush wheel feeder has a simple structure and is easy to maintain. Its rotating brush design effectively prevents material adhesion, ensuring even feeding. Although its speed is relatively slow, it performs exceptionally well in small-batch, multi-variety production, making it an ideal choice for small and medium-sized pharmaceutical companies. A drawback is its poor adaptability to high-speed production lines. For irregularly shaped tablets or shallow cavities in aluminum-aluminum blisters, the rotating brushes and scrapers may push already placed tablets or capsules out of the cavities, causing empty blisters. To address this issue, blister packaging machines are usually equipped with camera inspection and rejection systems. If empty blisters or damaged tablets or capsules are detected, they can be identified and removed to ensure product quality.

So, how should we choose the feeding system for irregularly shaped tablets, aluminum-aluminum blister packaging machines, or high-speed roller blister packaging machines?

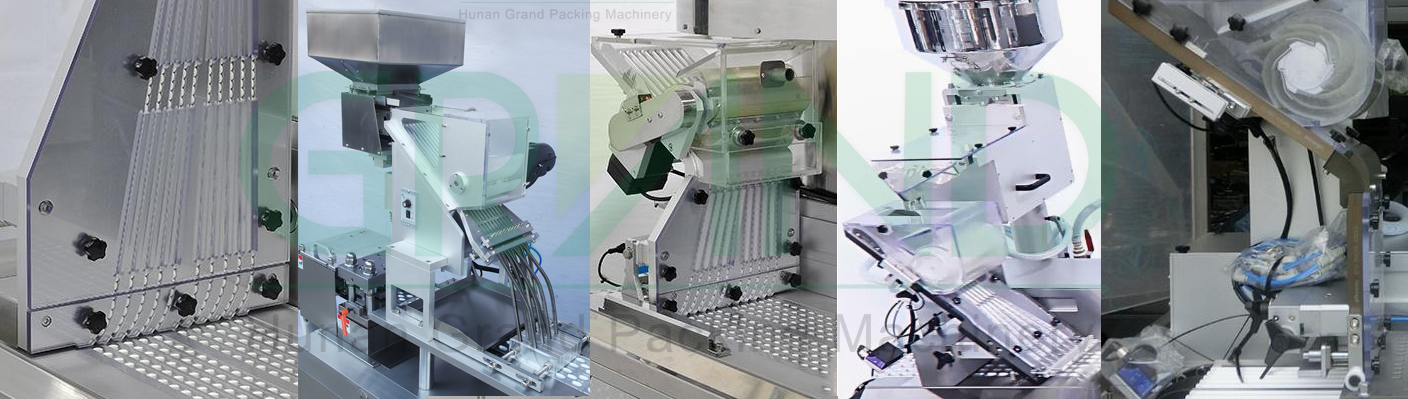

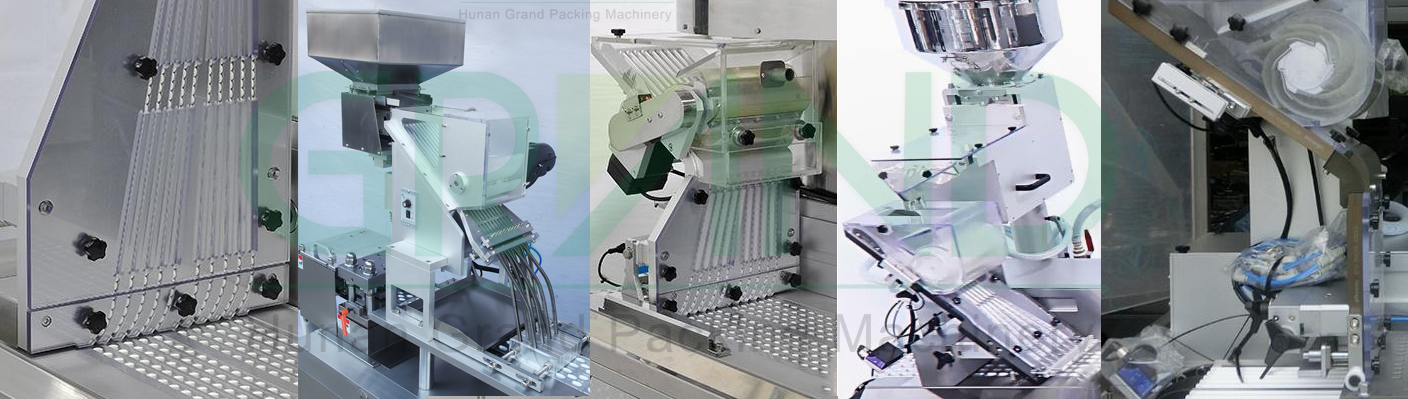

2、Special Feeder for Irregular Tablets

The special feeder is an efficient and optimal solution for feeding various solid products, especially irregularly shaped tablets. This system is suitable for all types of blister machines and is easy to install.

This unique feeding system, specifically designed for irregularly shaped tablets, can generally be divided into four types: rail feeders, roller feeders, gate feeders, and combined feeders. Among these, rail feeders are the most common method. We can select the optimal feeder based on the product shape and machine type. For example, rail feeders and roller feeders are suitable for high-speed roller blister packaging machines, while other combined feeders are suitable for flat-plate aluminum-aluminum blister packaging machines.

3、Roller Feeder

The rail + roller feeder ensures that irregularly shaped tablets smoothly enter the roller through precise rail guidance. The rotation of the roller accurately positions the tablets into the blister cavities, avoiding misalignment. This system is suitable for high-speed roller blister packaging lines and for tablets and capsules that require fixed orientation during packaging.

4、Classified Feeding System

The classified feeding system is designed to package different products in different cavities of the same blister sheet. For example, it can handle mixed packaging of tablets and capsules, or combinations of different types of tablets (e.g., Class A, B, C, or D drugs). Each type of tablet is supplied by a separate hopper and then guided into the required cavities via individual rails. This system is used for packaging combination drug products for treating specific diseases. The sorting feeding system enables precise combination and independent feeding of multiple drugs, ensuring each product is accurately placed in the blister sheet. The key lies in the coordinated operation of the hoppers and rails, as well as the precise control of the feeding sequence and quantity by the system. This system is commonly used for packaging combination drug therapies, such as multi-tablet regimens for chronic diseases. Since different drugs may vary in shape, size, and flowability, these factors must be carefully considered during system design to avoid blockages or misplacement. Additionally, the equipment should be easy to clean and adjust to accommodate different product changes, ensuring production efficiency and product quality.

5、Semi-Automatic or Manual Feeding

When the product is too unique for automatic feeding or when cost considerations preclude the use of automatic feeding systems, blister packaging machines may use manual feeding. Examples include loading ampoules, toys, and syringes. Semi-automatic feeding typically involves sorting and arranging the incoming materials before manually placing them into the blisters. Compared to fully manual methods, semi-automatic feeding reduces worker workload and is slightly faster, but it still cannot match the speed of automatic feeding.

Applications: Vials, ampoules, syringes, toys, or other irregularly shaped products.

6、 Robotic Automatic Feeding System

The robotic feeding system is an automated device for loading non-standard products such as ampoules, vials, and syringes into blister cavities. The products are conveyed to the robotic gripping station via an upstream production line. Using pre-programmed gripping routines, the robot uses clamps or suction cups to pick up one or more products and place them into the blister cavities, ensuring precise positioning. The robotic automatic feeding system is suitable for high-precision, high-efficiency packaging needs, particularly for large-scale production. Its flexible gripping and placement functions ensure accurate product positioning in the blister sheet, reducing human error. The system can integrate visual inspection to further enhance quality control. The robotic feeding system requires the product to be slightly smaller than the blister cavity to facilitate easy gripping and placement, ensuring packaging speed and accuracy.

7、 Vibrator+ Flexible Pneumatic Gripper Feeding

Condoms are sorted via a vibratory bowl track and then placed into the blisters using pneumatic flexible grippers. The robotic flexible pneumatic gripper achieves gentle gripping and placement through precise air pressure control, ensuring accurate positioning of the condoms in the blister sheet and avoiding damage. This system is suitable for automated feeding of sensitive products.

Applications: Condoms, electronic components.

Now, here’s a question for you: For triangular tablets with triangular blister cavities, which feeding method would you choose?

More details,pls contact us!

Ava Duan

Email: sales@grand-packing.com

whatsapp/wechat:86-13787413551

English

English