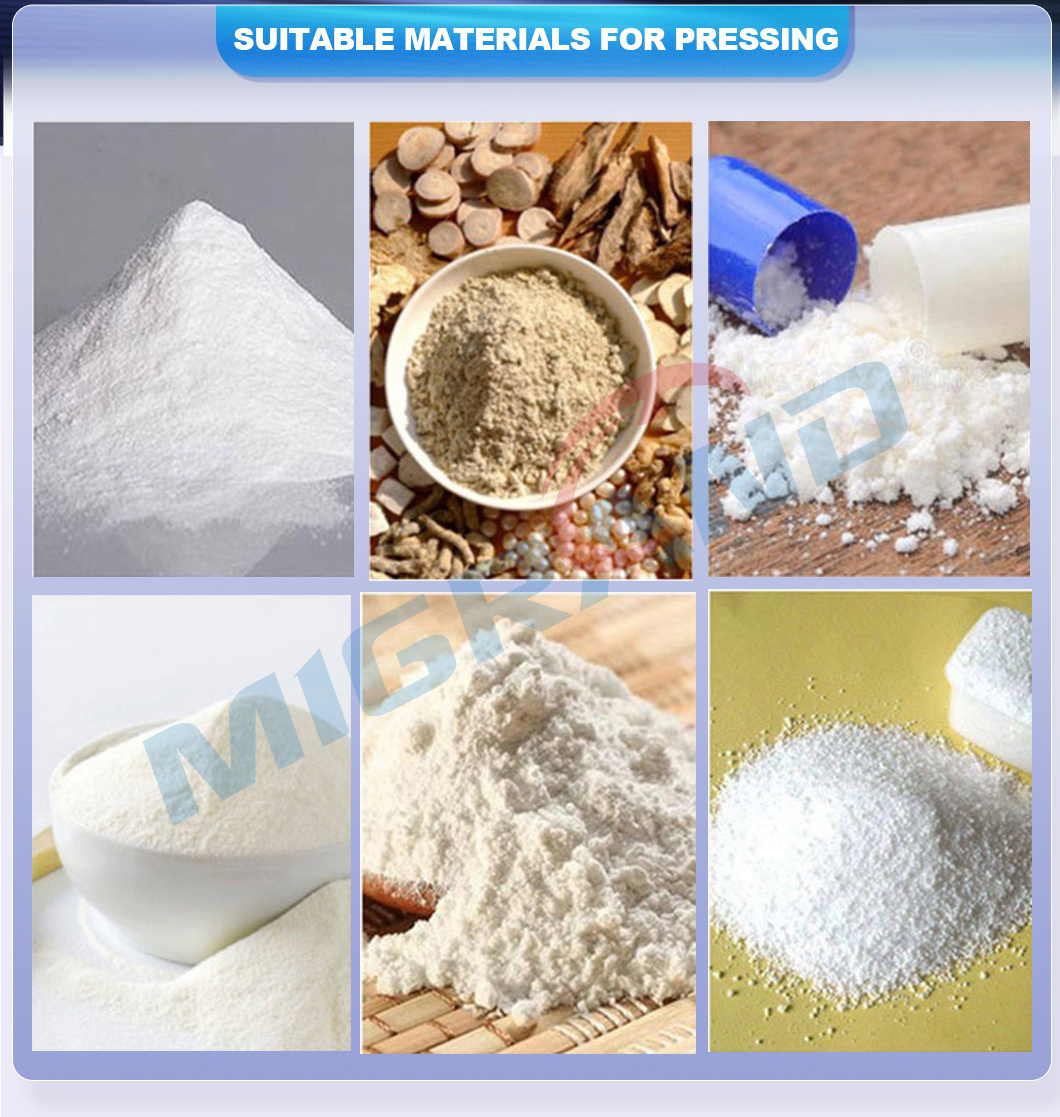

The common excipients of tablets are often examined in the primary pharmacists examinations, but because the tablet production is not only used in pharmaceutical industry, but also commonly used in daily chemicals, such as compound fertilizer effervescent tablets, Vitamin C candy effervescent tablets, automobile glass water effervescent tablets, etc.

(1) Filling agents

It is mainly used to add weight or volume of the tablet so as to facilitate tablet pressing. Commonly used fillers are starch, sugar, cellulose, inorganic salts, etc.

① Starch: Often corn starch. Poor compressibility, if used alone, the pressed tablets is too loose.

② Powdered sugar: Strong adhesion, can be used to increase the tablet hardness. While it is generally not used alone for its strong hygroscopicity.

③ Dextrin

④ Lactose: Excellent tablet filler, with good fluidity and compressibility, and can be used for direct tablet pressing from powder.

⑤ Compressible starch: Also known as “pregelatinized starch”, with good fluidity, compressibility, self-lubricity and dry adhesion, and good disintegration.

⑥ Microcrystalline cellulose (MCC): Good compressibility and strong adhesion, and can be used as a "dry adhesive" for direct powder compression.

⑦ Inorganic salts, such as calcium sulfate and calcium hydrogen phosphate. Often calcium sulfate dihydrate . However, calcium sulfate interferes with the absorption of some main medicine (tetracyclines) and should not be used in this condition.

⑧ Mannitol: Suitable for preparing chewable tablets.

(2) Humectant and adhesives

Some medicine powders have stickiness, and its inherent stickiness can be induced only by adding appropriate liquid. The added liquid is called humectant. Some other medicine powders have no stickiness or less stickiness, and need to add sticky substances such as starch slurry to make them stick together. And the added sticky substances are called adhesive.

① Distilled water: Distilled water is a humectant. Since some materials tend to absorb water quickly and causing uneven wetting, it is better to use starch or ethanol with low concentration instead.

② Ethanol: Ethanol is also a humectant. It can be used for medicine that are easy to decompose or too viscous in water.

③ Starch slurry: Starch slurry is the most commonly used adhesive in tablets. There are two main methods to prepare starch slurry: boiling and flushing.

④ Sodium carboxymethyl cellulose (CMC-Na): Adhesive and often used for medicine with poor compressibility.

⑤ Hydroxypropyl cellulose (HpC): Adhesive for wet granulation and direct powder compression.

⑥ Methyl cellulose and ethyl cellulose (MC; EC): Methyl cellulose has good water solubility and is used as adhesive; Ethyl cellulose is insoluble in water and often used in sustained and controlled release preparations (matrix type or membrane controlled release type).

⑦ Hydroxypropyl methyl cellulose (HpMC): The most commonly used coating materials.

⑧ Other adhesives: gelatin solution, sucrose solution, aqueous solution or alcohol solution of polyvinylpyrrolidone (pVp).

(3) Disintegrant

In addition to sustained (controlled) release tablets and some tablets with special effects, disintegrants should be added to general tablets.

The effervescent disintegrant generates gas when it immerses in water and disintegrates. There are some other mechanisms: soluble raw materials and excipients dissolve in water to cause disintegration or erosion of tablets; surfactants can improve the wettability of granules and promote disintegration; corresponding enzyme added in excipients for better disintegration due to enzymolysis, etc.

① Dry starch: It is the most classical disintegrant, suitable for tablets of water-insoluble or slightly soluble medicines. While it has poor disintegration effect to soluble medicines, the reason is: it can be dissolved in water, resulting in concentration difference, then the water outside the tablets is not easy to penetrate into the tablets through the solution layer, hindering the water absorption and expansion of starch inside the tablets. In production, external addition, internal addition or "internal and external addition" is generally used to achieve the desired disintegration effect.

② Carboxymethyl starch sodium (CMS-Na): It is a disintegrant with excellent performance because of its remarkable swelling effect.

③ Low-substituted hydroxypropyl cellulose (L-HpC): It has high water absorption speed and good water absorption capacity.

④ Cross-linked polyvinylpyrrolidone (Cross-linked pVp)

⑤ Croscarmellose sodium (CCNa)

⑥ Effervescent disintegrant

(4) Lubricant

Lubricant is a general term for fluidizer, antiadherent and lubricant (in a narrow sense).

① Magnesium stearate: Magnesium stearate is a hydrophobic lubricant.

If inordinately large doses in medicines, the tablet disintegration will be slow due to its hydrophobicity.

② Superfine silica powder: It is a fluidizer and can be used for direct powder compression.

③ Talcum powder: mainly used as a fluidizer.

④ Hydrogenated vegetable oil: It is a lubricant with good lubricating performance.

⑤ Polyglycols and MgLS: Typical water-soluble lubricants. Polyglycols mainly are polyglycol 4000 and 6000, MgLS is a water-soluble lubricant.

(5) Others

Surfactant: some tablets dissolution is required to dissolve slowly in specified mediums, so appropriate surfactant is added to improve the dissolution, such as sodium dodecyl sulfate.

If you have any questions during tablet pressing, please communicate with us.

English

English