PP Blister / Tray / Caps Forming Machine

Product Description

The machine is an automatic multi-station blister/plastic tray thermoforming machine with positive and negative pressures, including 450S/450A/550A and other models, which is designed by our company according to years of technology accumulation and different customer requirements.

In particular, PP-500 and PP-350 are innovative machines independ ently developed by our company with obtained invention patents. The machines effectively solve the problems of large production investment, complex workflow process, poor product hygiene and low security of plastic products such as PP/PS/PET/PVC/PLA, etc.

These machines are capable to complete forming, piercing, punching and other processes synchronously, to quickly and efficiently produce products with plastic package. So they are very suitable for packaging food, medicine,

hardware, gifts and other products. Moreover, the machine is stable, beautiful and cost-effective, widely selected by customers in domestic and abroad!

Key features:

1) Compact structure, stable operation, easy operation and convenient maintenance;

2) Adopts servo adjustment and touch screen;

3) Adjustable moving stroke, and simple to replace molds;

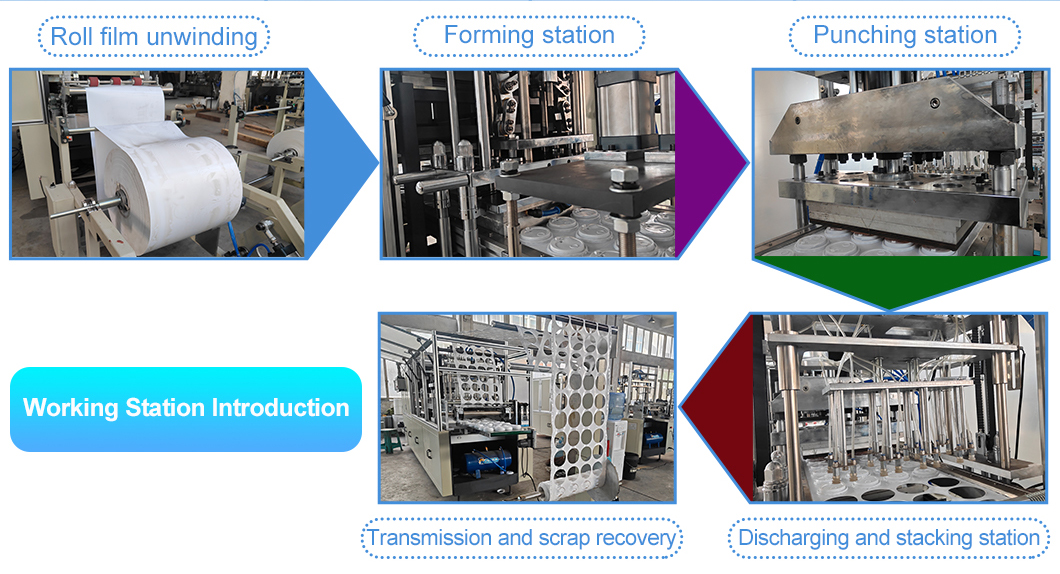

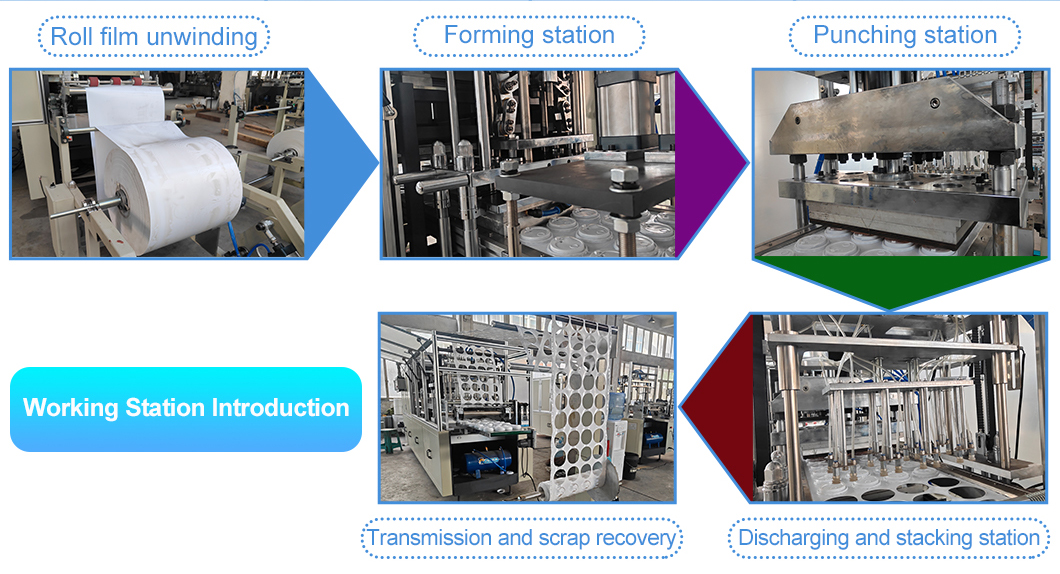

Working process:

The production process: Packing film heating --> blister forming --> servo motor traction --> piercing --> blister plate punching --> waste collection.

Machine model list

Machine parameters

| Model | PP500 | GP550A | GP450A | GP450S |

| Application | Widely used in PET, PVC, HIPS and other plastic covers in medicine, food, daily necessities, electronics, hardware and other production |

| Speed | PP 10-13times/min

PVC/PET 12-20 times/min | 15-35times/min |

|

| Materials | PP, PVC, PET, HIPS, PLA, GPPS | PVC/PET/HIPS/PLA |

| Total Power | 40KW | 6KW | 4KW |

|

| Cooling mold | Tap or recycled water, with 60L/hour consumption |

| Air consumption | > 0.9m³/Min | >0.6m³/Min |

| Max. forming width | 500mm | 300mm | 300mm | 130mm |

| Max. forming area | 450*260mm | 550mm | 450mm | 450mm |

| Max. forming depth | 50mm | 46mm | 46mm | 46mm |

| Overall dimension | 5300*1500*1900mm | 4000X1300X1900 | 4000X1200X1900 | 2600X1100X1700 |

| Machine weight | 3200kg | 2400kg | 2200kg | 1100kg |

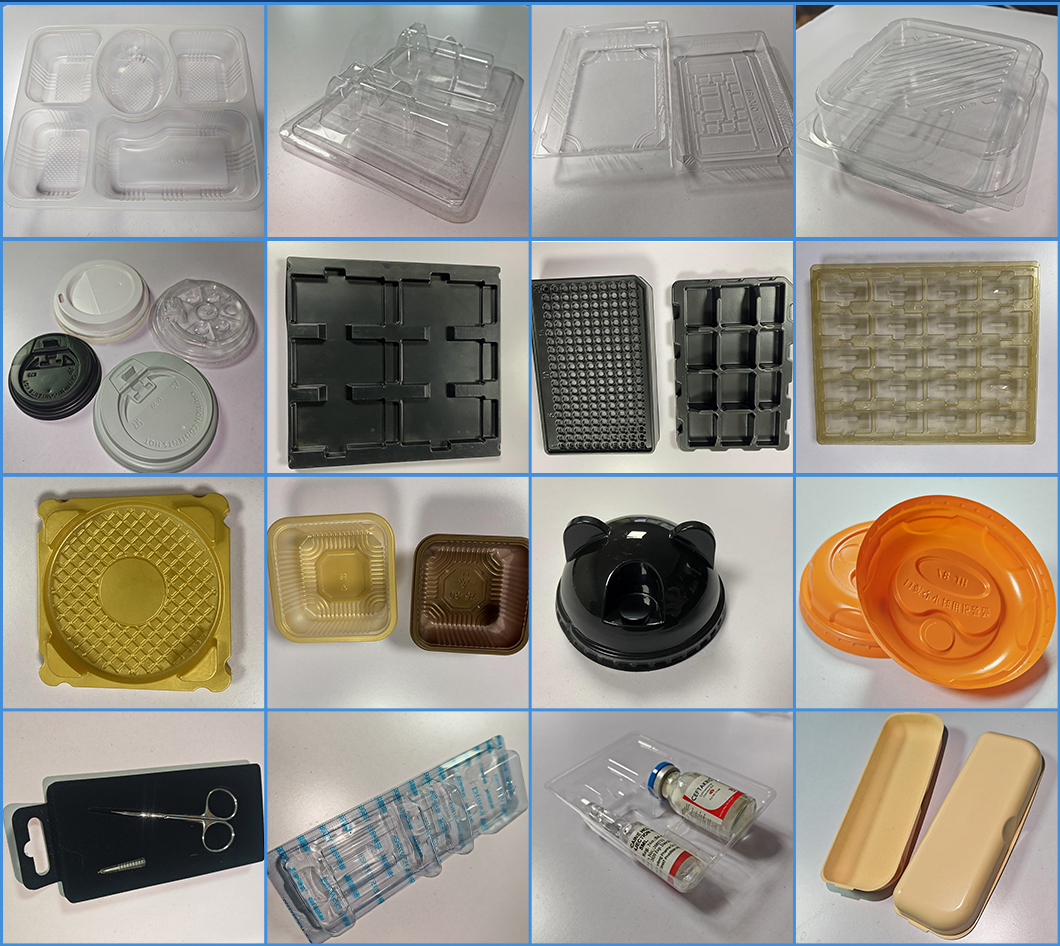

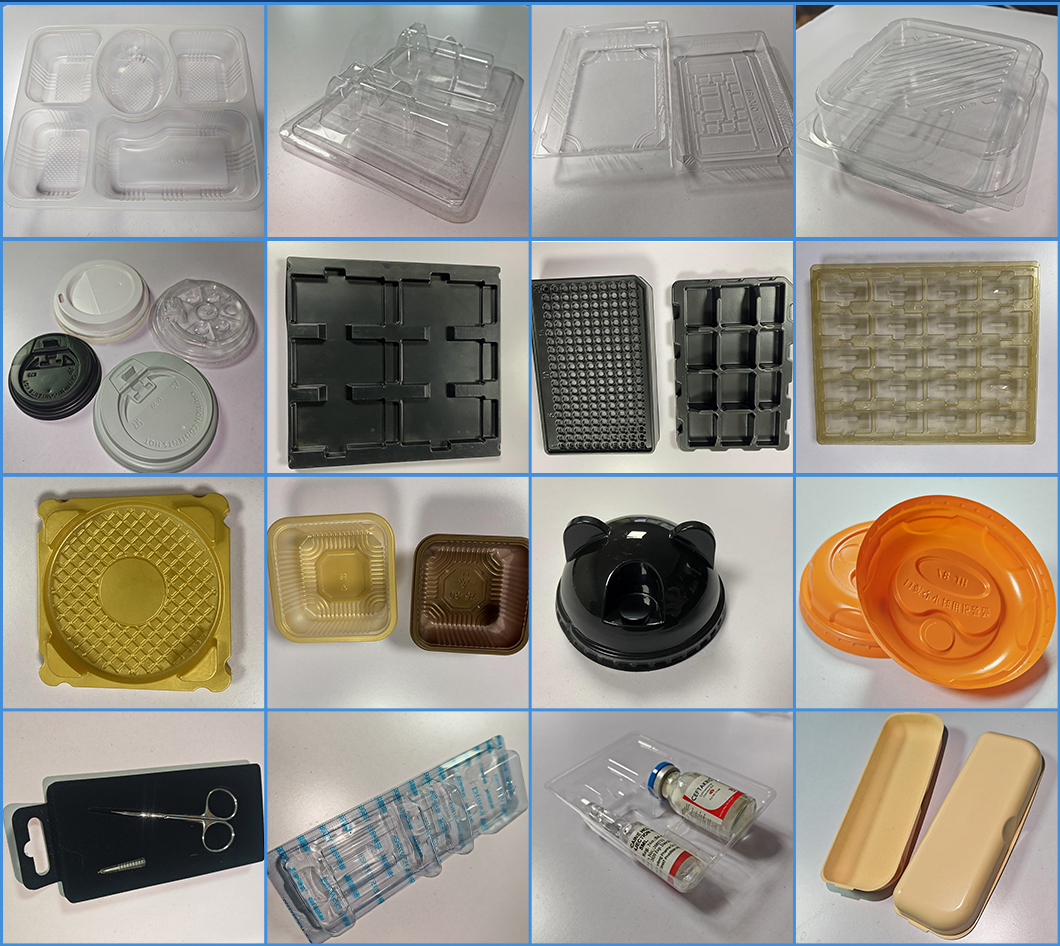

Sample Display

Machine details

PP500 electrical components list

No. | Code | Name | Model/specification | Qty | Remark |

1. | QF1 | Plastic case circuit breaker | NM1-125S/3300/100A | 1 | CHINT |

2. | QF2 | Miniature circuit breaker | DZ47-63/3P-15 | 1 | CHINT |

3. | QF3-QF18 | Miniature circuit breaker | DZ47-63/1P-25 | 16 | CHINT |

4. | QF19-QF26 | Miniature circuit breaker | DZ47-63/1P-10 | 8 | CHINT |

5. | QF27 | Miniature circuit breaker | DZ47-63/1P-16 | 1 | CHINT |

6. | QF28 | Miniature circuit breaker | DZ47-63/1P-5 | 1 | CHINT |

7. | KM1 | AC contactor | CJX2-0910 | 1 | CHINT |

8. | FV1 | Power protector | DPA51CM44 | 1 | JIALE |

9. | SSR1-SSR16 | Solid relay | KSR-40DA-H | 16 | YANGDIAN |

10. | SSR17-SSR25 | Solid relay | KSR-25DA | 9 | YANGDIAN |

11. | SSR26-SSR27 | PLC output amplifier | S40193N-8/DC24V | 2 |

|

12. | KA1-KA3 | Miniature relay | JZX-22F(D)/2Z/DC24V | 3 | CHINT |

13. | TC1 | AC-DC converter module | LRS-100-24 | 1 | MEANWELL |

14. | PLC1 | PLC | CPU-ST30/SMART | 1 | SIEMENS |

15. | PLC2 | Extension module | EM-DT08/SMART | 1 | EURA |

16. | PLC3-PLC6 | Temperature module | AX6-C | 4 | AIXER |

17. | U1 | Servo driver | SDP20 | 1 | EURA |

18. | M1 | Servo motor | SMSA-102G33EDK | 1 | EURA |

19. | SBE1-SBE2 | Emergency Stop button | XB2-BS542A | 2 | GOELE |

20. | SBS1 | STOP button | XB2-BA42A | 1 | GOELE |

21. | SB1-SB2 | START button | XB2-BA31A | 2 | GOELE |

22. | SB3 | JOG button | XB2-BA51A | 1 | GOELE |

23. | S1 | Encoder | ME38S6M-1000R24F3K4 | 1 | MOGOK |

24. | UF1 | Frequency inverter | 380V/3.0kw | 1 | EURA |

25. | M2 | Vacuum pump | / | 1 |

|

26. | SQP1-SQP2 | Proximity switch | KM12-04N | 2 | YANGMING |

27. | YV1 | Forcing valve for punching | / | 1 | AIRTAC |

28. | YV2 | Limit valve of center guide | / | 1 | AIRTAC |

29. | YV3 | Upper heating plate valve | / | 1 | AIRTAC |

30. | YV4 | Negative pressure valve for punching | / | 1 | AIRTAC |

31. | YV5 | Blowing valve for forming | / | 1 | AIRTAC |

32. | YV6 | Stretching valve for forming | / | 1 | AIRTAC |

33. | HL1 | Alarm light | HT-50A | 1 |

|

34. | HM1 | Touch screen | MCGS-7022EX | 1 | KUNLUN TONGTAI |

35. | X1 | Solenoid valve | 4V410-15/24V | 5 | AIRTAC |

36. | X2 | Solenoid valve | 4V210-08/24V | 5 | AIRTAC |

37. | A1 | Main motor | 3KW-4P B3 | 1 | YEB |

38. | A2 | Conveying motor | 4PK25GN-CZ/4GN | 1 | LPG |

39. | A3 | Waste collecting motor | 5RK60GU-CZ/5GU-15-K | 1 | LPG |

Please contact me for design and quotation details.

Ava: +86-13706885851 (Whatsapp/Wechat)

Email: sales@grand-packing.com

English

English