Automatic Single-Multi Wet Tissue & Wipes Making Machine Composite Films Flow Pack Back-Seal Baby Wet Wipes Pillow Packing Machine Line

This type of machine adopts vertical folding and lower film feeding, and the operation is fast and stable.

It is suitable for automatic packaging of multi sheet Wet wipes. (such as 5sheets/10-50sheets, etc.)

The machine uses servo motors and a PLC touch panel to configure the machine parameters.(E.g. Temperature, packing speed, length of wipes , etc.)

The production speed can reach 20-600 sheets/minute according to different packaging quantities.

Functions:

Roll feeding, liquid adding,wet tissue folding, wet tissue cutting, wet tissue counting and stacking, packing , sachet back-sealing, sachet pillow sealing and cutting output, date printing (optional), labeling(optional) ,finished product conveyor output (optional).

Main Features

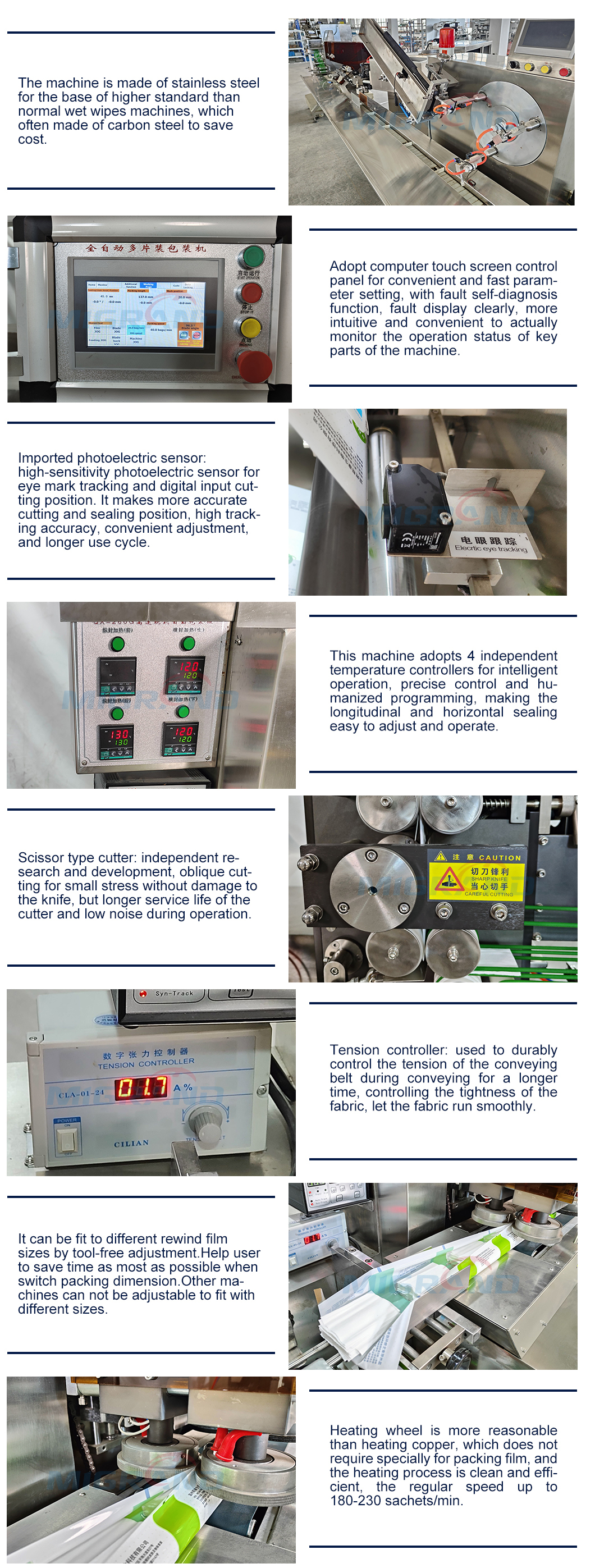

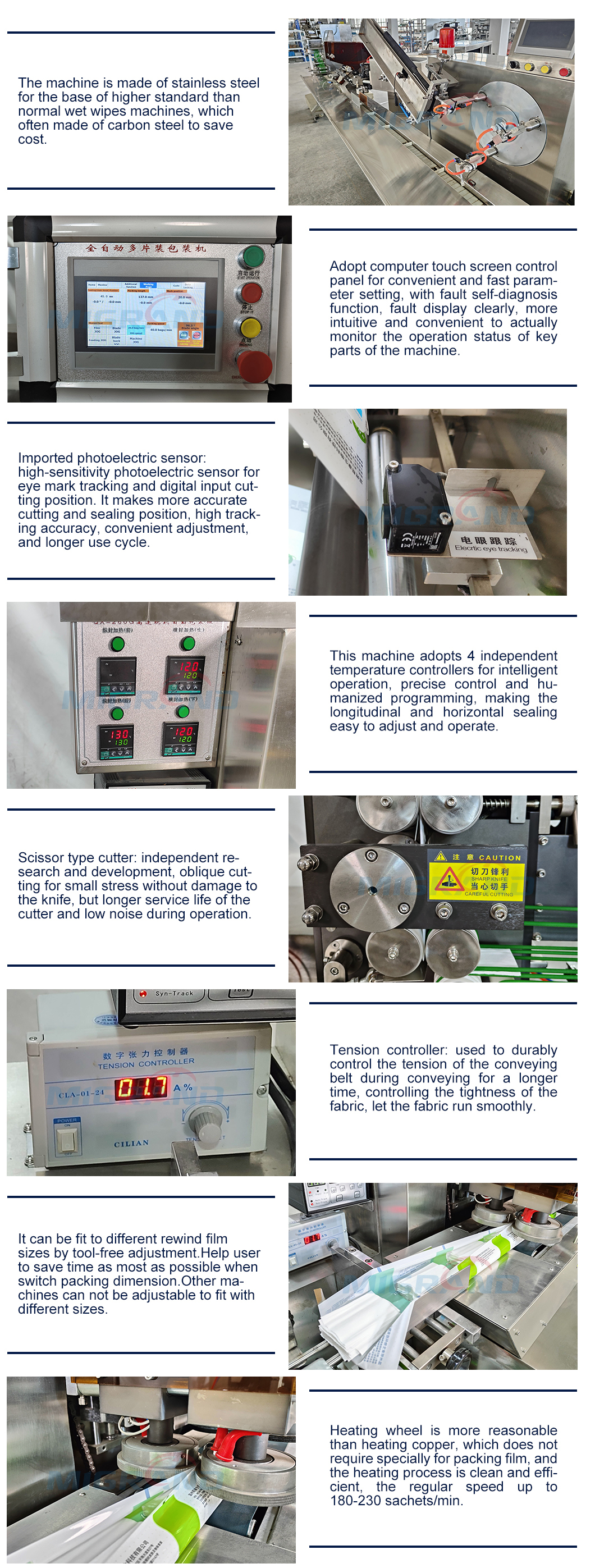

1: The whole machine adopts the domestic advanced full servo motor for drive control with high control accuracy, low noise, strong overload capacity, fast speed, stable operation and more reliable control.

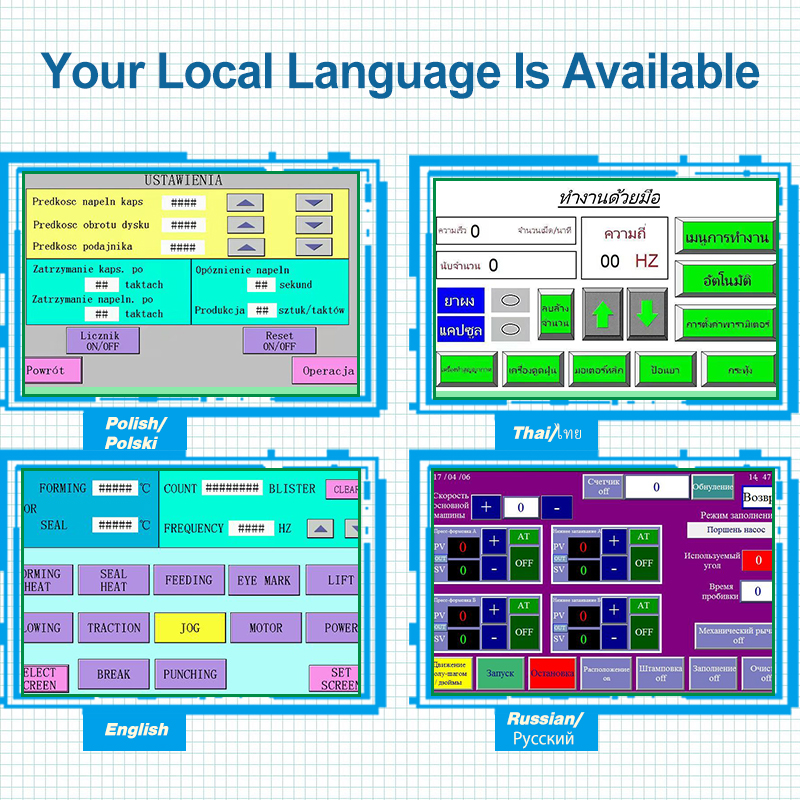

2: Adopt computer touch screen control panel for convenient and fast parameter setting, with fault self-diagnosis function, fault display clearly, more intuitive and convenient to actually monitor the operation status of key parts of the machine.

3: Imported photoelectric sensor: high-sensitivity photoelectric sensor for eye mark tracking and digital input cutting position. It makes more accurate cutting and sealing position, high tracking accuracy, convenient adjustment, and longer use cycle.

4: This machine adopts 4 independent temperature controllers for intelligent operation, precise control and humanized programming, making the longitudinal and horizontal sealing easy to adjust and operate.

5: Scissor type cutter: independent research and development, oblique cutting for small stress without damage to the knife, but longer service life of the cutter and low noise during operation.

6: Tension controller: used to durably control the tension of the conveying belt during conveying for a longer time, controlling the tightness of the fabric, let the fabric run smoothly.

7: Equipped with positioning and shutdown function: stop freely without packing film waste, sticking to the cutter and damage to the cutter.

8: The transmission system is simple while more reliable, and more convenient to maintain.

9: All controls are realized by software, which is convenient for function adjustment and technical maintenance.

Product Parameters

| Model | GH-260G | GH-260B | GH-260D | GH-260X | GH-350 |

| Name | High Speed single sheet wipes packing machine | 1-5 sheet wipes

packing machine | 1-10 sheet wipes packing machine | 5-50 sheet wipes

packing machine | Hotel wet towel

packing machine |

| Capacity | 30-370 bag & sheet / min | 20-200bag/min,

20-300sheet/min | 20-200bag/min,

20-600sheet/min | 20-200bag/min,

20-900sheet/min | 20-100bag/min |

| Bag size (L * W * T) | 80-350mm*30-120mm*

0-35mm | 80-400mm*30-120mm*0-35mm | 80-400mm*30-120mm*

1-65mm | 80-300mm*30-160mm* 1-35mm |

| Film size (L * W) | 80-160mm*80-260mm | 80-400mm*80-260mm | 80-400mm*80-350mm |

| wipes size (L * W) | 70-280mm*80-280mm | 70-300mm*80-280mm | 70-280mm*80-280mm |

| G/m2 | 30-120g/m2 | 30-250g/m2 |

| Rated voltage | 220V or customized |

| Total power | 50HZ 4.5KW | 50HZ 5.5KW | 50HZ 6.5KW | 50HZ 7.5KW | 50HZ 6KW |

| Machine weight | 730KG | 800KG | 1200KG | 1400KG | 1500KG |

| Overall dimension | 2500X1500X1700 | 4500*1500*1700 | 4900*1500*1900 | 5900*1500*1900 | 2800*2300*2200 |

| Max diameter of roll | Non-woven:1000mm, Film:400mm | Non-woven:750mm,

Film:400mm |

| Packaging material | OPP PET CPP Matt film, pearlescent film, aluminum film, extinction film, paper film, zinc film and other composite films |

Questions about parameters?

Which model do you think is more suitable for you? or need customized?

Click to contact me.

Detailed Photos

Machine catalog

3&4sides sealing wet tissue sample

Our Services

Service 3: We will dispatch engineers to your site for machine installation and commissioning, and also do the training for your technicians.

Service 4: We makes guarantee of the machine for 12 (twelve) months. During this Warranty period, the seller will provide free spare parts that cause by the machine’s quality within 10 days by fast courier upon receipt of buyer’s notice.(we will also provide one set of spare parts /wear &tear parts to customer along with the shipment of the machine.

Service 5: We warmly welcome the suggestions from customer to make us grow better and produce better machine along with providing better service to customer, and create more value for customer.

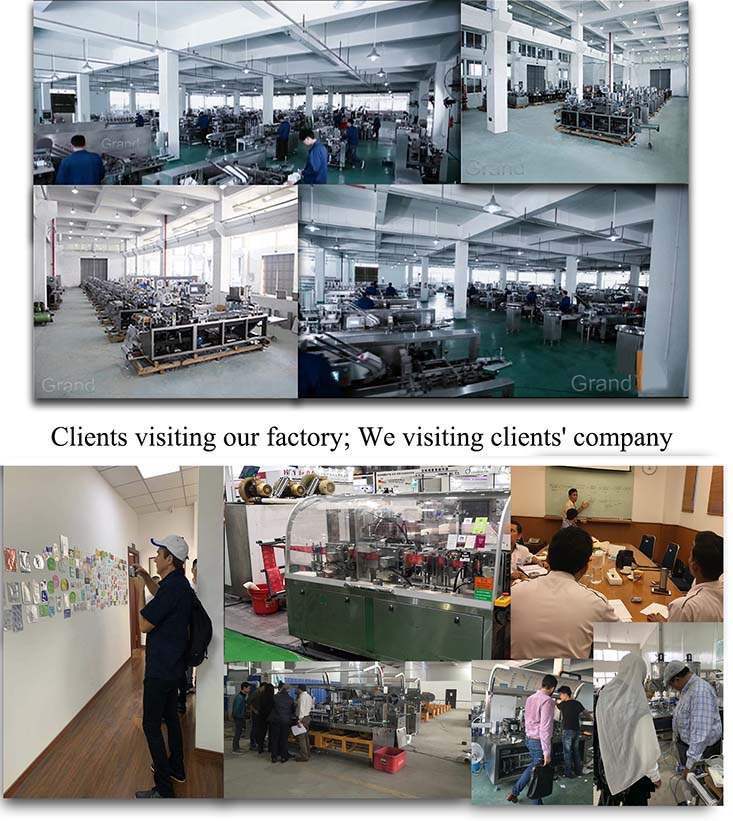

Service 6: Before placing the order or before shipping, welcome to our factory to take a visit to inspect our machine. we will pick you up in the airport or train station and arrange your following schedule in our city to bring you a nice journey during this visit.

Company Information

ABOUT US

Hunan Grand Packing Machinery Co.,Ltd is specialized in the pharmaceutical and packing machinery for more than 10 years, such as plastic ampoule forming filling and sealing machine, capsule filling machine, blister packing machine, strip packaging machine, cartoning machine etc. We have provided services and machines to many different countries and regions in the whole world, such as Indonesia, Thailand, Malaysia, Philippines, New Zealand, Korea,the Middle East area, Poland, Belgium, France, UK, Greece, Italy, Turkey, USA, central and south America such as Trinidad and Tobago,Mexico, Brazil, Russia, Ukraine, UZ, Tunisia, Algeria, Morroco etc. And we always gain the good reputation from customer both from the machine quality and after sales service.

customer visit at our factory and our visit to customer

Our factory

We are cooperating with various kinds of factories and companies in different fields, including pharmaceutical factory, food factory, supplement factory, agrochemical factory such as for pesticide, fertilizer, personal care product factory, such as for cosmetic product, daily use product, stationery factory, hardware factory etc.

English

English