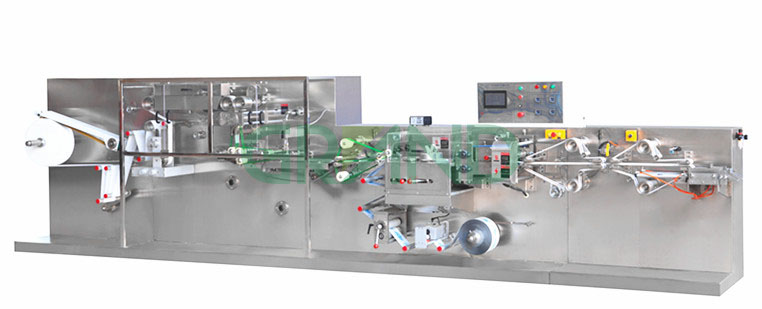

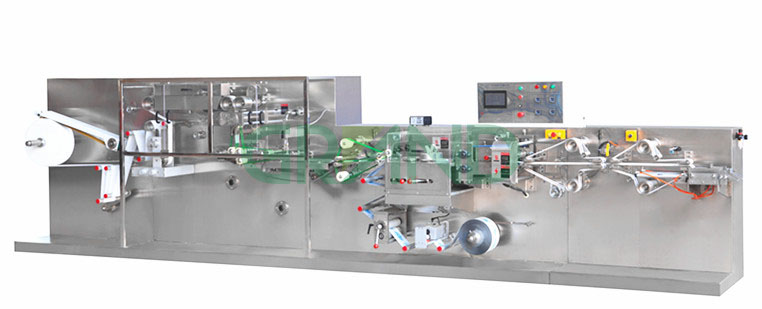

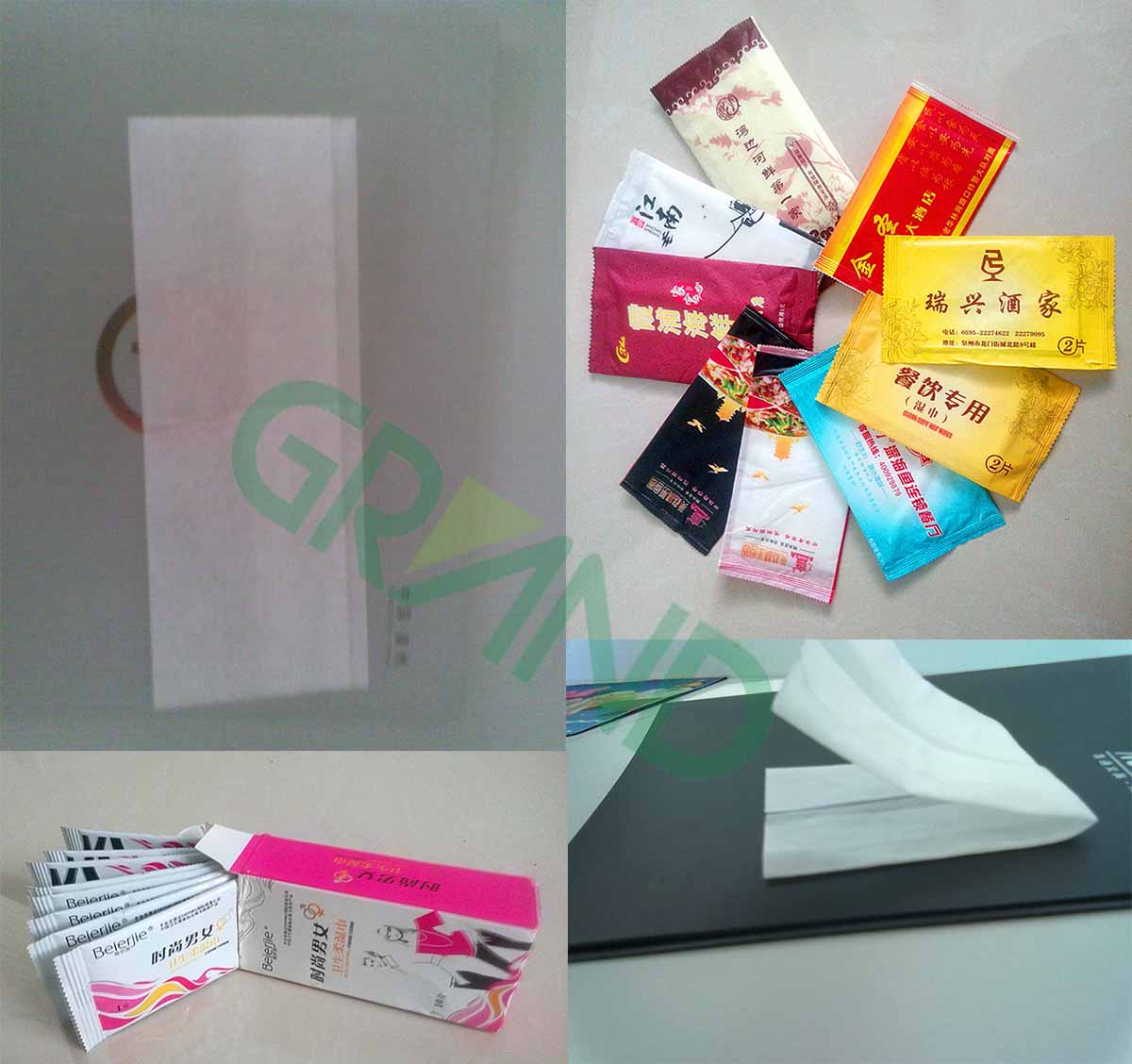

Automatic Single Piece Wet Tissue Packing Machine

1.Product:

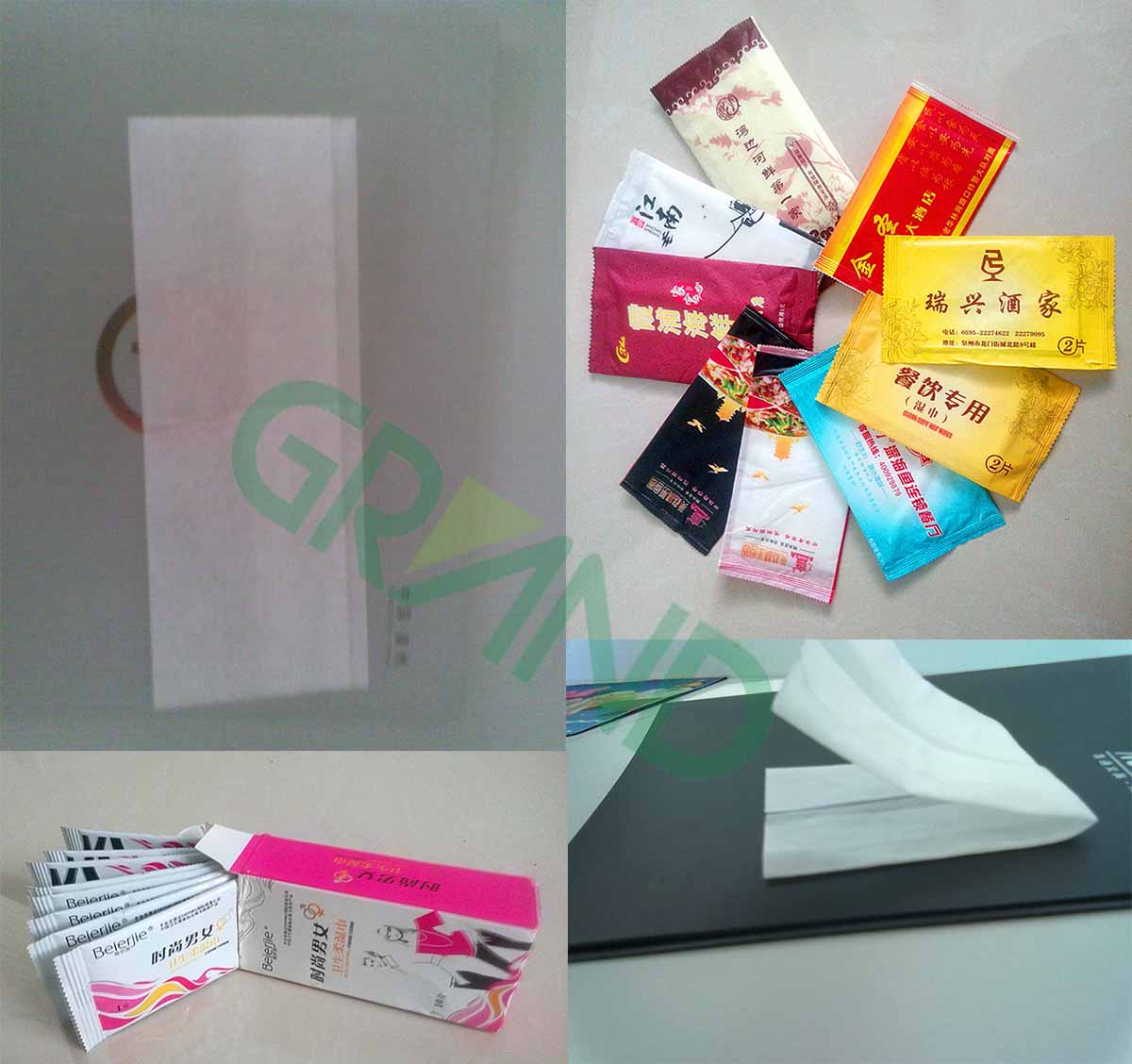

Wet tissue (single piece)

2.Flow chart:

Raw material→(processes on machine)→end product discharging

Raw material unwinding→vertical folding→medical liquid feeding online→material dividing at certain length→horizontal folding→stacking→film releasing→packing→vertical sealing→horizontal cutting→final product output→rejection setting→wipe sorting setting→sachet packing

3.Main technical parameters

| Model | HY-200 |

| Power supply | 380V, 50Hz |

| Total power | 7KW |

| Appropriate raw material | Dust-free cloth, spunlace nonwoven |

| Material specification | (150-250)*1000mm (W*D) |

| Material weight | 35-80g/m2 |

| Wipe size | (140-250)*(150-250)mm (L*W) |

| Folded wipe size | (70-125)*(45-80)mm (L*W) |

| Packing film | OPP/PE, PET/PE |

| Production speed | 150-200pcs/min (depending on practical materials) |

| Net weight | 2000Kg |

| Machine dimensions | 5600*900*1650mm (L*W*H) |

| Humidifying | Automatic humidifying system (with stirring and circulating functions) |

| Coding | Automatic coding |

| Liquid storage barrel | Dimensions | 800*800mm (D*H) |

| Volume | 400L |

| Optical fiber at sachet packing station | PANASONIC |

| Optical fiber for cutting | PANASONIC |

| Optical fiber for crimping | PANASONIC |

| Wipe sorting and counting photo-electricity | OPTEX |

| Sorting | Pneumatic motion |

| Rejecting | Air blowing |

| Driving | Frequency conversion of main motor |

| Film feeding | Stepping motor |

| Operation panel | Touch screen |

| Wipe sorting quantity control | 5-20pcs (set on touch screen) |

| Wipe sorting speed | 60 sachets/min |

| Wipe sorting conditions setting | A.Wipe sorting quantity setting (on touch screen); |

| B.Position detection for wipes packing in sachet being on/off (set on touch screen); |

| C.Crimping detection being on/off (set on touch screen); |

| D.Cutting detection being on/off (set on touch screen) |

4.Main features

1)Spunlace nonwoven is synchronously fed;

2)Roller sealing device;

3)Electrical differential for phase control without machine shutdown;

4)Adjustable length;

5)Main electrical appliances are all bought from famous brands;

6)Framed machine chassis.

5.Main configuration

1)Vertical spunlace nonwoven folding device;

2)Spunlace nonwoven humidifying device;

3)Wet cloth cutting device. High speed steel cutter is applied and can be changed;

4)Horizontal spunlace nonwoven folding device;

5)Automatic wipe counting, rejecting and count stacking device;

6)Packing film forming device;

7)Vertical film sealing device;

8)Horizontal film sealing device;

9)Frequency control of main motor;

10)Motor+synchronous belt+planetary reducer for driving;

11)Liquid feeding control system, applying immersing squeezing control;

12)Electromagnetic valve and cylinder (AIRTAC);

13)Coding device: ink coding machine with coding speed no more than 300 times/min.

6.Main electrical configuration list

| No. | Name | Brand |

| 1 | Frequency converter | DANFOSS |

| 2 | Film feeding stepper and controller | JUST MOTION |

| 3 | EncoderKOYO | KOYO |

| 4 | HMI | WECON |

| 5 | PLC | FATEK |

| 6 | Solid relay | OMRON |

| 7 | Approaching switch | |

| 8 | Opposite fiber | PANASONIC |

| 9 | Cylinder | AIRTAC |

Our Services

Service 3: We will dispatch engineers to your site for machine installation and commissioning, and also do the training for your technicians.

Service 4: We makes guarantee of the machine for 12 (twelve) months. During this Warranty period, the seller will provide free spare parts that cause by the machine’s quality within 10 days by fast courier upon receipt of buyer’s notice.(we will also provide one set of spare parts /wear &tear parts to customer along with the shipment of the machine.

Service 5: We warmly welcome the suggestions from customer to make us grow better and produce better machine along with providing better service to customer, and create more value for customer.

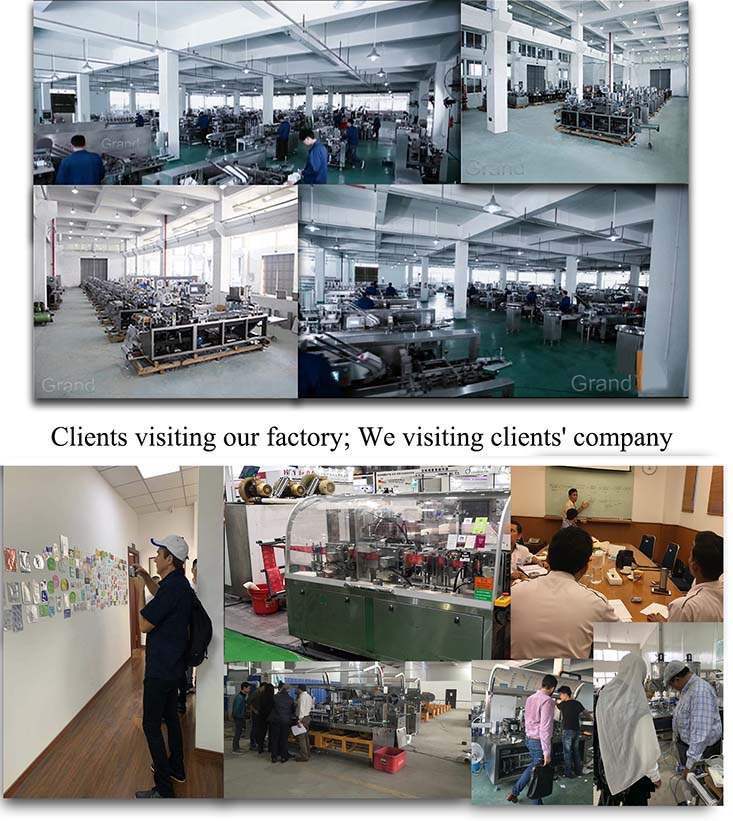

Service 6: Before placing the order or before shipping, welcome to our factory to take a visit to inspect our machine. we will pick you up in the airport or train station and arrange your following schedule in our city to bring you a nice journey during this visit.

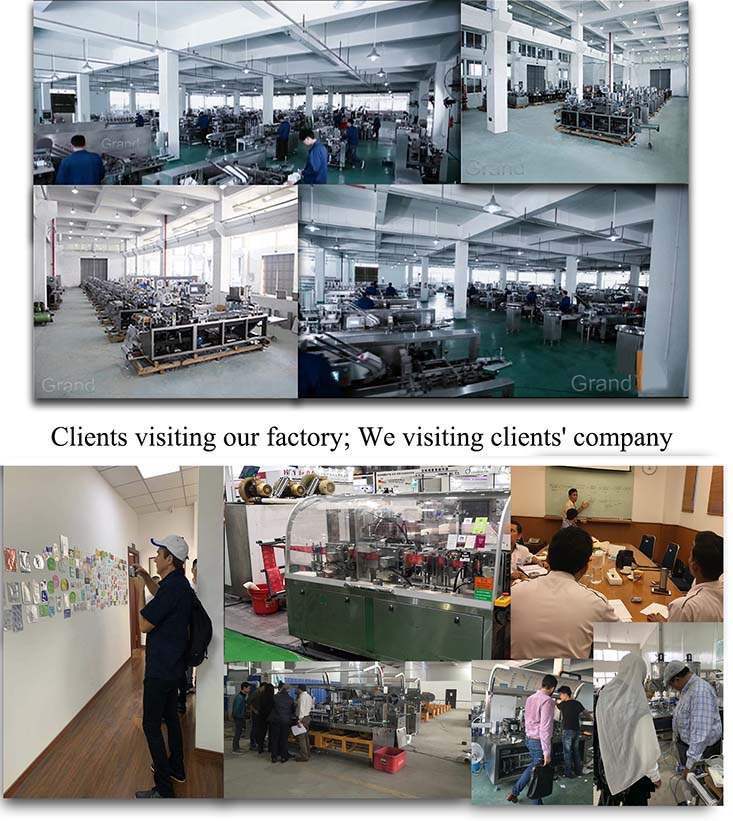

Company Information

ABOUT US

Hunan Grand Packing Machinery Co.,Ltd is specialized in the pharmaceutical and packing machinery for more than 10 years, such as plastic ampoule forming filling and sealing machine, capsule filling machine, blister packing machine, strip packaging machine, cartoning machine etc. We have provided services and machines to many different countries and regions in the whole world, such as Indonesia, Thailand, Malaysia, Philippines, New Zealand, Korea,the Middle East area, Poland, Belgium, France, UK, Greece, Italy, Turkey, USA, central and south America such as Trinidad and Tobago,Mexico, Brazil, Russia, Ukraine, UZ, Tunisia, Algeria, Morroco etc. And we always gain the good reputation from customer both from the machine quality and after sales service.

customer visit at our factory and our visit to customer

Our factory

We are cooperating with various kinds of factories and companies in different fields, including pharmaceutical factory, food factory, supplement factory, agrochemical factory such as for pesticide, fertilizer, personal care product factory, such as for cosmetic product, daily use product, stationery factory, hardware factory etc.

English

English