ZHJY-50 Filling & Capping Machine

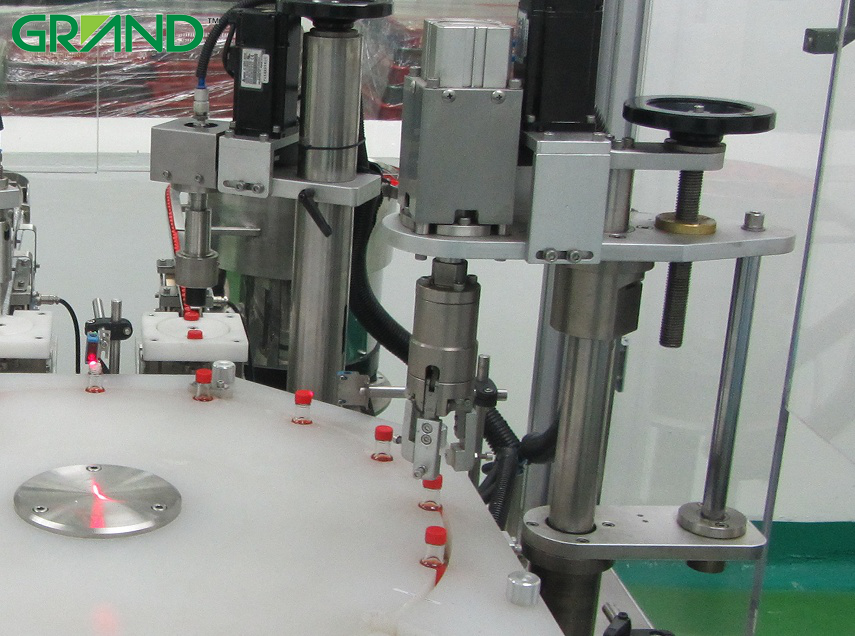

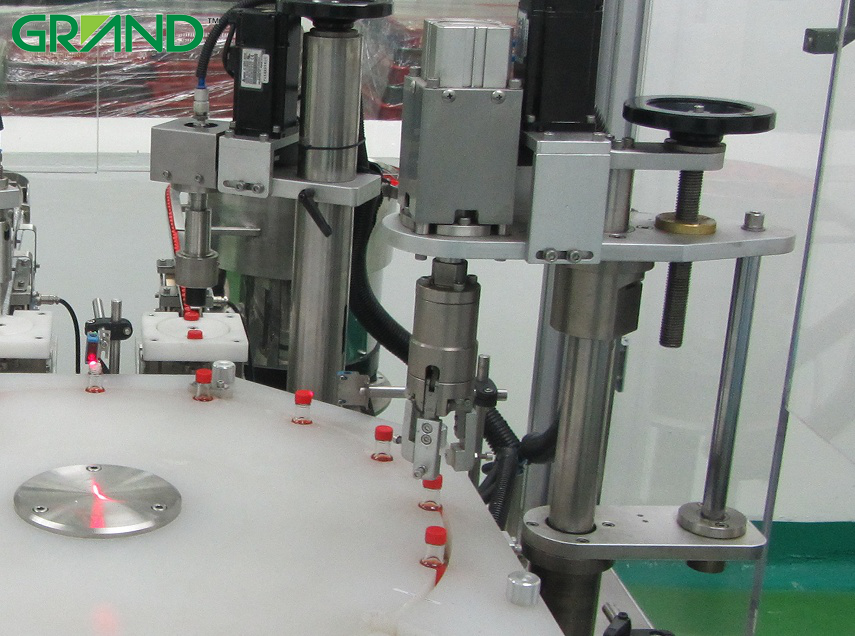

Filling and capping machine is the latest product developed by our company. PLC controls peristaltic pump (when material is of good liquidity) or piston (when material is viscous) to calculate and fill (Precision ceramic pump will be applied in special conditions). The machine acquires many functions such as filling automatically, stoppering automatically, capping, etc.. The machine is equipped with unique robots. The robots swing arms when stoppering and capping and can cap accurately. Torque mode of servo motor is applied when capping to coordinate the tightness and adjust the tightness conveniently to fulfill absolute automation.

1. PLC controls accurate filling volume and convenient operation.

2. The function of the filling system to suck back can be made to order to ensure no leak.

3. Robots stopper and cap automatically.

4. The function of stopping operation automatically is acquired. The machine stops operation automatically when no filling and no capping continuously appear in any conveyer.

Parameters

Appropriate volume | 5-20ml |

Production quantity | 30-40 per minutes |

Filling accuracy | (error) ≤±0.5% |

Power supply | 220V 50HZ |

Capping rate | ≥99% |

Automatically stoppering rate | ≥99% |

Air source | 2m³/h 0.4-0.8MPa |

Power | 1.0KW |

Net weight | 500Kg |

Dimensions (L*W*H) | 1530 * 2990 * 1900 mm |

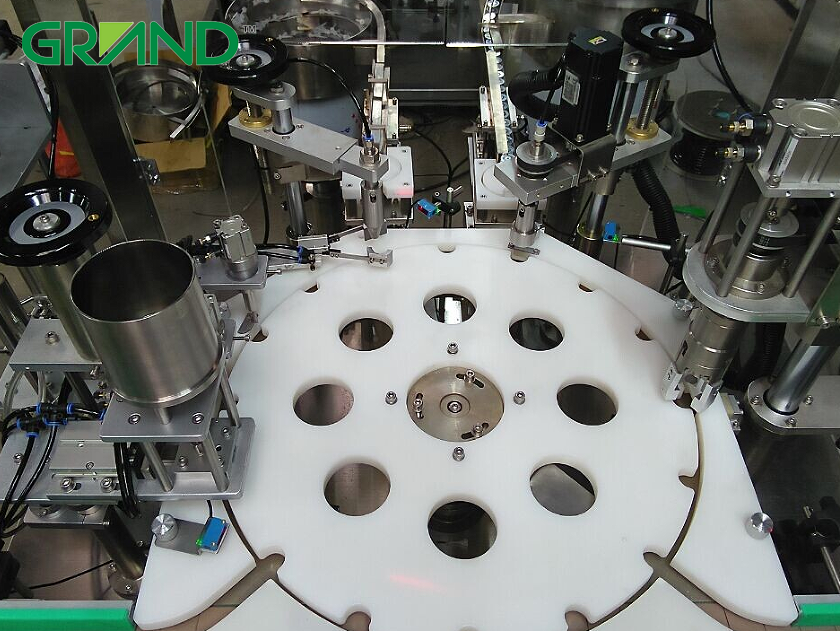

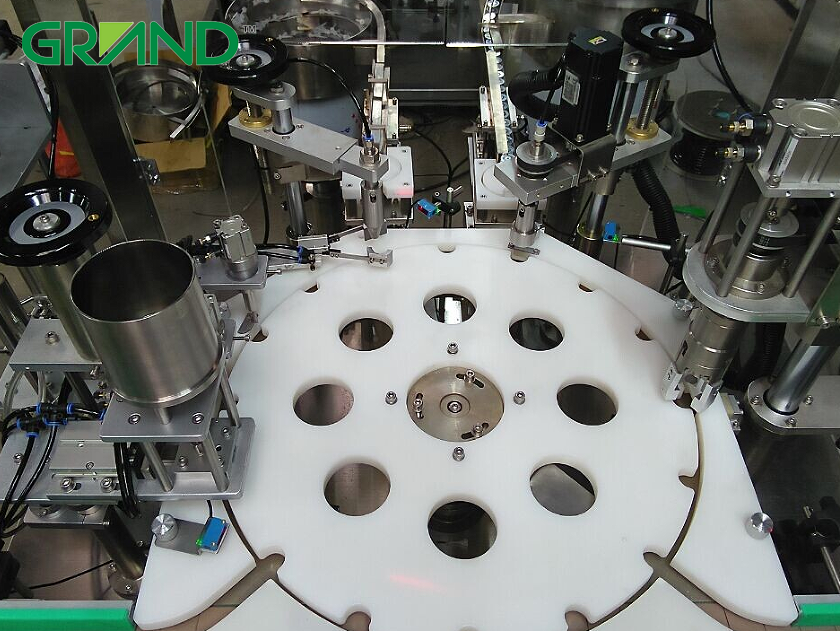

Filling in accurate volume, stoppering with swinging arms, covering, pre-capping, and capping by servo

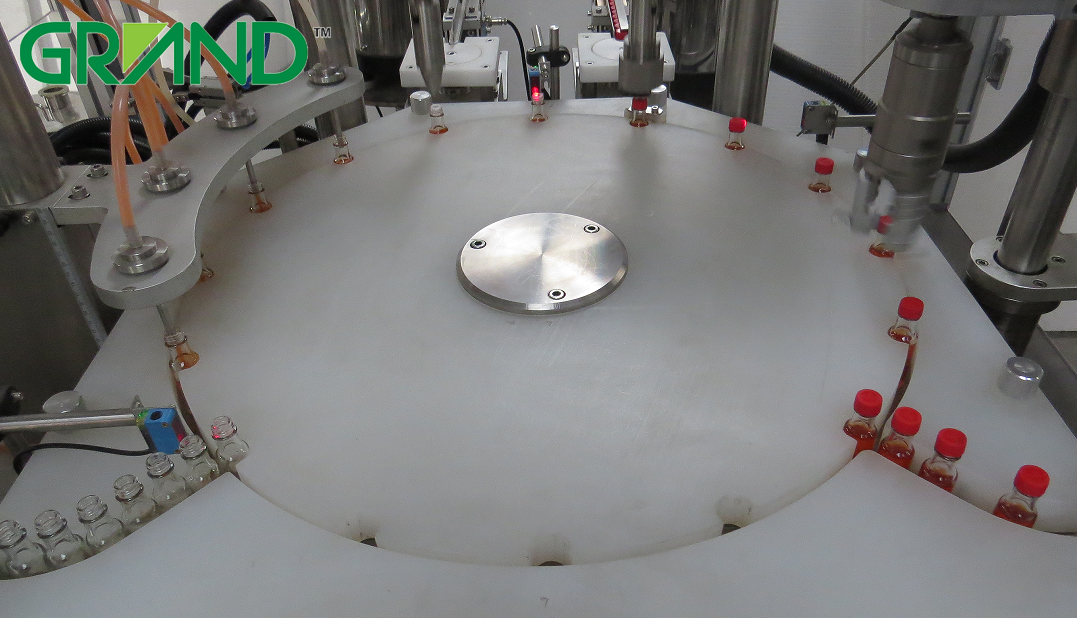

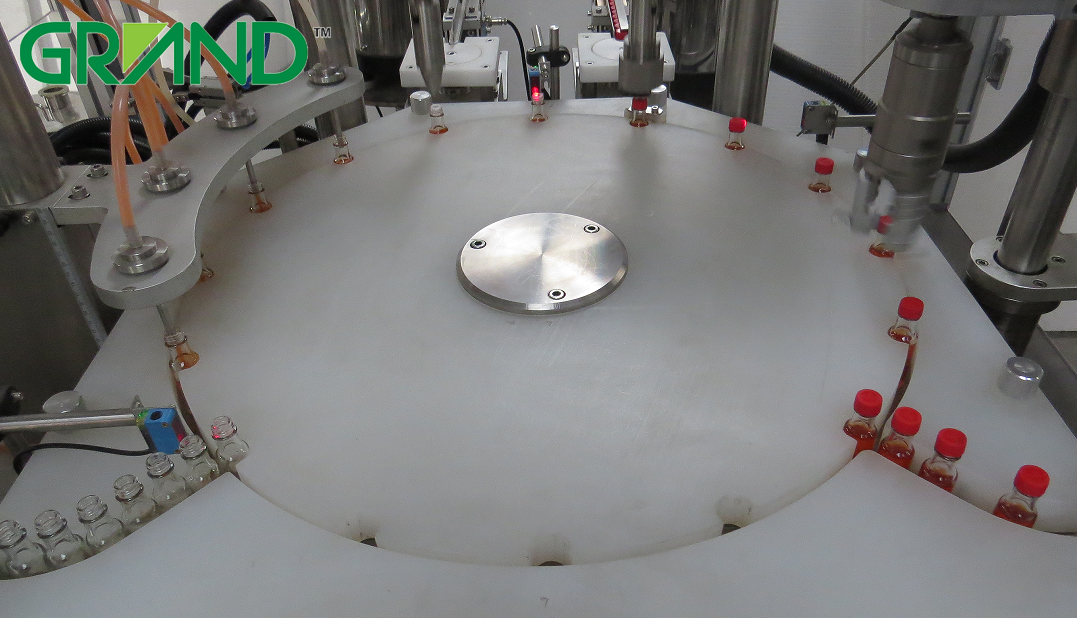

Stoppering with swinging arms, covering, pre-capping by servo

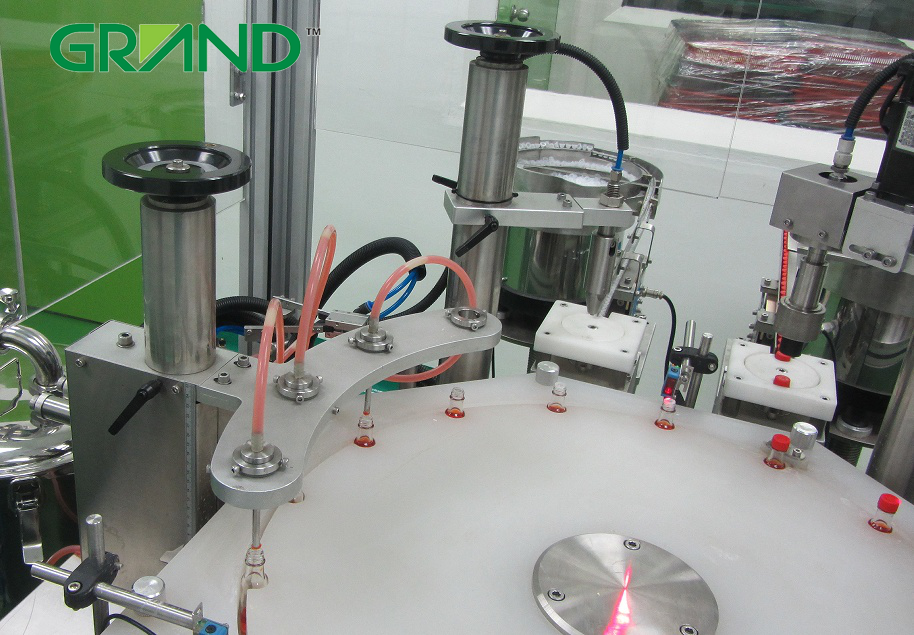

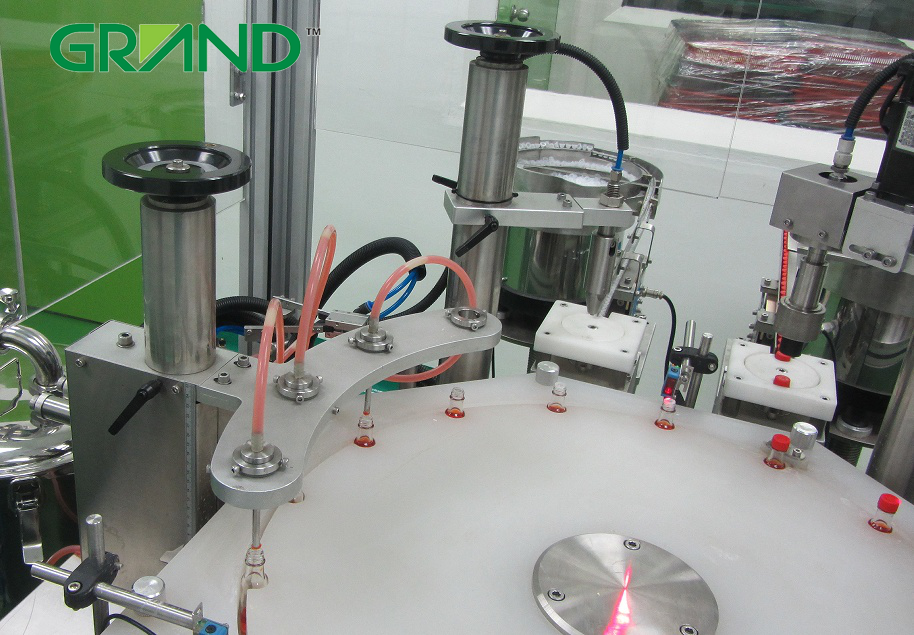

Covering, pre-capping, and capping by servo

Company Information

ABOUT US

Hunan Grand Packing Machinery Co.,Ltd is specialized in the pharmaceutical and packing machinery for more than 10 years, such as plastic ampoule forming filling and sealing machine, capsule filling machine, blister packing machine, strip packaging machine, cartoning machine etc. We have provided services and machines to many different countries and regions in the whole world, such as Indonesia, Thailand, Malaysia, Philippines, New Zealand, Korea,the Middle East area, Poland, Belgium, France, UK, Greece, Italy, Turkey, USA, central and south America such as Trinidad and Tobago,Mexico, Brazil, Russia, Ukraine, UZ, Tunisia, Algeria, Morroco etc. And we always gain the good reputation from customer both from the machine quality and after sales service.

Our Service

1.We will dispatch engineers to your site for machine installation and commissioning, and also do the training for your technicians.

2.We makes guarantee of the machine for 12 (twelve) months. During this Warranty period, the seller will provide free spare parts that cause by the machine’s quality within 10 days by fast courier upon receipt of buyer’s notice.(we will also provide one set of spare parts /wear &tear parts to customer along with the shipment of the machine.

3.We warmly welcome the suggestions from customer to make us grow better and produce better machine along with providing better service to customer , and create more value for customer.

4.Before placing the order or before shipping, welcome to our factory to take a visit to inspect our machine. we will pick you up in the airport or train station and arrange your following schedule in our city to bring you a nice journey during this visit.

English

English