In Europe, 85% solid preparations are packed in blisters while in America only 20%. However, as producers and consumers have realized the advantages of blister packaging, blister packaging is being accepted by more and more people in USA.

Packaging industry is one of the largest industries on a global scale. It totals 280 billion dollars. In the whole industry, value of health-care product packaging reaches 11.2 billion dollars (4%). And in the 21st century, pharmaceutical producers will face much more challenges and package can help them to meet some needs better.

About 10 years ago, many pharmaceutical companies ignored package and saw it as just the final step of production. But now they have to design their packages much earlier than drug development. Drug packages is quickly becoming a core part and factor for drug delivery system and marketing. Producers can distinguish their products and compete with their others by these packages. Need on drug package is increasing and will continue to increase as producers rely more on package and label to protect and popularize their products, improve patient’s compliance and conform to new regulations.

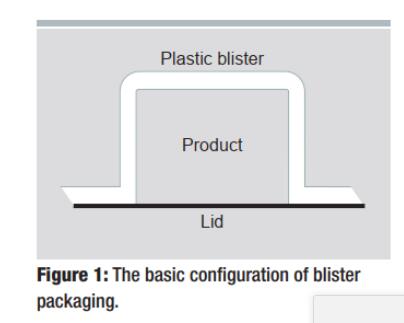

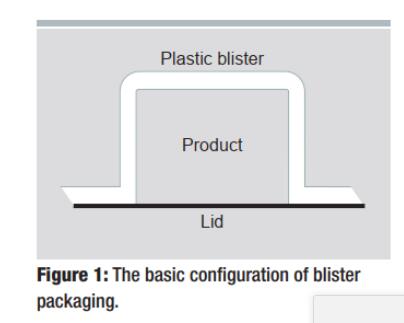

1. Basic structure of blister package

There are two kinds of blister package for drugs. The first kind of blisters consists of transparent and thermoformed cavity and composite film cover made from transparent film, plastic, paper or foil; the other kind is composed of cold formed cavity and cover.

Early to 1960, Karl Klein invented the first stamping blister packing machine. But he had no patent on this machine because European pharmaceutical industry was not interested in it at all at that time until acyeterion came out. Schering Pharmaceutical Ltd (Berlin, Germany) selected blister packaging for this revolutionary product because it seemed that it was the most proper package for effective drug taking.

It can be seen that accurate dosage for patient was the most important reason for application of blister package. Therefore, patients can check if they had taken prescribed drugs in one day. Besides, the unused drugs can be kept and protected by the package well. Compared with traditional package, blister can be dealt with and stored more easily.

Soon later, producers realized other advantages of blister package. For example, glass bottles broke but blister didn’t. Besides, packing film for blister package can cost lower but be processed at higher speed. Another obvious advantage was that blister package can evidence usage. As a result, blister package used to be tamper-evident. All of these advantages explained why about 85% solid preparations in Europe is packed in blisters.

2. Application of blister package in USA and Europe

On the contrary, almost all prescription or over-the-counter drugs are packed in bottles. Till now, only less than 20% non-liquid drugs are packed in blisters.

Why is there such a disparity in blister packaging between Europe and USA? Firstly, during the Second World War, packing machinery were destroyed just as something others in Europe. The pharmaceutical producers chose blister packing machines instead of bottle packing machines when they had to start their production from the very beginning. Secondly, European countries set looser regulations on child-resistance closures than USA. Thirdly, the fitness program was different in these two areas. Most medical program was limited in 10-14 days in Europe, while about 30-60 days in USA, since the insurance companies permitted a longer supply period. In addition, drugs sold less in Europe. Therefore, it was prone for producers to pack drugs in blisters for lower cost. Last but not least, EU introduced stronger measures to promote application of blister packaging. For example, producers would be punished if they used too much packing material. Blister packaging, however, was of the smallest size.

3. Blister package for medicine in USA

Pharmaceutical producers and consumers have realized advantages of blister packaging and accepted it well. In fact, blister packaging can help patient take drugs in accurate dosage, protect drugs during shelf life and make drugs to be carried conveniently. The advocates list five advantages of blister package in comparison with other common packages, namely product integrity, protecting products, being tamper-evident, reducing accidental use and patient compliance.

1) Product integrity

Prescribed drugs at the retail level is disturbing in USA. Pharmacist or pharmaceutical technicians inventory drugs in supermarket or pharmacy where sensitive drugs are transferred from one container to another. During transferring, many factors can have negative influences on these sensitive drugs.

But blister packaging can be useful to keep products’ integrity. The blister can shield the drugs from adverse conditions. Besides, it’s hardly possible for drugs to be contaminated. Each dosage is also marked by product name, production lot and expiry date. Therefore, blister packaging ensures product integrity for consumers.

2) Protecting products

Drugs in blisters can be better protected than that in bottles. For example, many consumers store drug bottles in the medicine cabinet in their bathroom. However, a bathroom can be full of steam periodically. As a result, once bottles are opened in such a condition, the nature of unused drugs will have some change immediately. On contrary, blisters can store tablets or capsules in their cavity. The unused drugs can be protected in the original package well from external influences. Before being taken, moisture-sensitive drugs are protected by the blisters well. By comparison, drugs packed in bottles will be contaminated by the steam every time the bottles are opened.

3) Being tamper-evident

Tamper-evident technology is another advantage of blister packaging. Unit dose is sealed in the plastic, foil or paper blister separately. Such design makes sure that the patient can only take the drugs only when they tear the blister open without leaving no evidence. However, any tamper-evident mechanism will be of no use once the bottles are opened. But tablets or capsules in blisters can all be prevented from tampering since any tampering will be found by the broken package.

4) Reducing accidental use

Blister packaging can also function for child resistance and currently a lot of such designs are applied. Most child-resistant blisters contain peelable adhesive. The patient have to peel the adhesive firstly before use and then take out the drugs. 15-mil PVC can protect the blisters from children’s biting. And some enterprises are also developing the material which taste bitter to prevent those children.

5) Patient compliance

The last advantage of blister packaging is the patient compliance. Among all prescription drugs, about 30% drugs are not taken correctly and 50% are not used in a year. Such abuse will result to a lot of side effects and even death.

Healthcare Compliance Packaging Committee (HCPC, Washington) was founded in 1990. This non-business organization aims to make consumers, professionals and decision-makers in healthcare filed know more about blister packaging in drugs compliance. Some study results of HCPC are listed as follows:

a. A total of 1.8 billion prescriptions are prescribed each year, half of which are wrong;

b. 10% of hospitalizations were due to irregular medication;

c. Financial loss caused by irregular medication can reach 13-15 billion dollars;

d. 23% of the aged in the sanatorium is unable to take their drugs correctly at home;

e. About 125,000 Americans die from taking drugs not as directed;

f. The aged consumes about 50% prescription drugs, which makes drugs abuse worse.

In addition, blisters can be printed with bar code to avoid mistakes in medication. From the point of view of drugs compliance, pharmacists have more opportunities to talk with patients and give advice for them for less medication time is needed.

Blister use is increasing in USA. For example, New York and New Jersey states regulate that hospitals shall adopt unit-dose blister packaging and medication system. The report by New Jersey Hospital Pharmacists Association also shows that such unit-dose system leads to only a few mistakes. Logically speaking, more states will introduce similar regulations.

English

English