Product Description

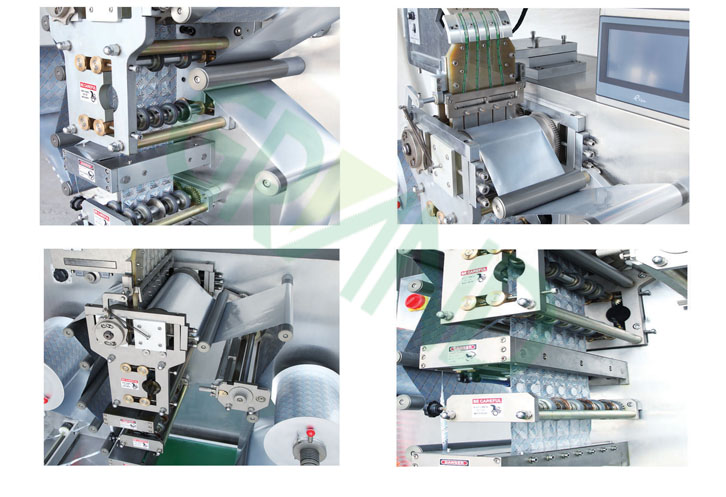

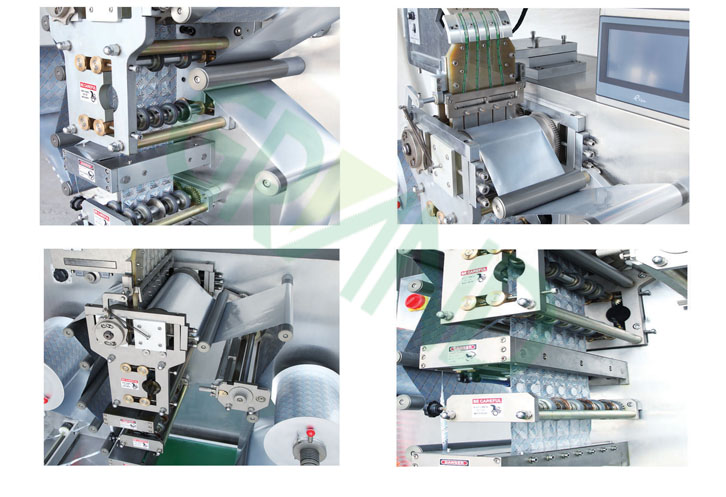

NSL-350B is a new generation of automatic double-aluminum strip packing machine, the latest developed product of our company. This machine is novel in design and advanced in structure. It adopts PLC touch screen control system and has such advantages as high efficient, low noise and easy operation. It’s equipped with material feeding structure, which applies vibrating type for arrangement, and equipped with photoelectric monitor device. This machine can control feeding material automatically, set the cutting plates optionally and finish the procedures of material conveying, material charging, sealing, imaginary line, batch no, cutting and counting automatically. In addition, it can run with high speed. This machine is suitable for packing all kinds of tablets, capsules with double-aluminum strip in pharmaceutical and health product industries, and the similar tablet-shaped electronic components in electron industry; with good sealing and light-tight effect, it greatly prolongs the quality guarantee period of product, and the finished products are easy to take.

Performance Characteristics

1. The machine shell is welded by 304 stainless steel plate with 2mm thick. The models of NSL-260 and NSL-350 are equipped with protective door for safe operation, beautiful and practical.

2. It adopts PLC control system with touch screen. The cutting sections of medicine plate can be set and adjusted optionally on the touch screen, which can perfectly avoid the problem of changing all kinds of gears and cams for the change of packing specification and medicine type.

3. It adopts imported temperature controller with PID to control the temperature of sealing mould, and high-level PT100 roller surface temperature-detector assembled by imported components to measure the temperature. On one hand, it can ensure that the surface temperature of sealing mould is absolutely stable and reliable; on the other hand, it directly improves the seal effect of medicine plate.

4. It adopts stepless frequency converter, running stably and reliably, simple drive structure, convenient to maintain.

5. This machine can also be equipped with other optional functions such as solid-ink roll coding, image marking, optical fiber detection for material lacking, and waste rejection to meet various needs of different customers.

Technical Parameters

| Capacity:30-90 thousand pcs/hour | Punch frequency:30~80times/min |

| Packaging area:350mm× any length | Main motor power: 0.75KW |

| Material roll DIA:300 mm | Total power:4KW |

| Machine Dimension (L×W×H): 1600×950×1900 mm | Air compressor:0.5Mpa |

Packing Dimension (L × W × H):

1800×1200× 2100mm | Gross weight:1200 kg |

Sample Display

Company Information

ABOUT US

Hunan Grand Packing Machinery Co.,Ltd is specialized in the pharmaceutical and packing machinery for more than 10 years, such as plastic ampoule forming filling and sealing machine, capsule filling machine, blister packing machine, strip packaging machine, cartoning machine etc. We have provided services and machines to many different countries and regions in the whole world, such as Indonesia, Thailand, Malaysia, Philippines, New Zealand, Korea,the Middle East area, Poland, Belgium, France, UK, Greece, Italy, Turkey, USA, central and south America such as Trinidad and Tobago,Mexico, Brazil, Russia, Ukraine, UZ, Tunisia, Algeria, Morroco etc. And we always gain the good reputation from customer both from the machine quality and after sales service.

Our Service

1.We will dispatch engineers to your site for machine installation and commissioning, and also do the training for your technicians.

2.We makes guarantee of the machine for 12 (twelve) months. During this Warranty period, the seller will provide free spare parts that cause by the machine’s quality within 10 days by fast courier upon receipt of buyer’s notice.(we will also provide one set of spare parts /wear &tear parts to customer along with the shipment of the machine.

3.We warmly welcome the suggestions from customer to make us grow better and produce better machine along with providing better service to customer, and create more value for customer.

4.Before placing the order or before shipping, welcome to our factory to take a visit to inspect our machine. we will pick you up in the airport or train station and arrange your following schedule in our city to bring you a nice journey during this visit.

English

English