1.Working Principle and application

R320 four-side sealing stretch packing machine can pack products with PVC film. For the best packing effect, forming mold and heat sealing mold are both reasonably designed according to products’ overall dimensions.

It can also realize the vacuum packing for food, so it will make the food stay fresh for a longer time.

At first, driving chain drives PVC to pass through forming mold and be formed to designed shape. Two or more workers feed materials in material feeding zone. Then the semi-finished product will be vacuum sealed by heat sealing mold. The high-precision sealing device can make sure that packages are stably and reliably sealed. Next, packages are processed in cutting station. Corners of packages will be processed. At last, end products are discharged.

If client’s products are special, a foam pad can be used to cover acute corners of product packages after material feeding. Therefore, packing sachet can be protected from damage of acute corners, packing standard upgraded and packing life also prolonged.

Application: it is suitable for the packing of mask,food, meat products, seafood, vegetable and fruit, pickles, chilled meat, medical products, hardware components and medical instruments of relatively irregular shape.

2.Control system

1)Controlled by leading PLC of Delta;

2)6-inch color HMI touch screen of Delta and pull-push control panel;

3)Servo system control of Delta for high speed and high precision;

4)Chain of TYC, cylinder and electromagnetic valve of Airtac for precise machinery coordination;

5)Low-voltage electrical appliance and perfect safety protection measures.

3.Main functions

1)The machine is of photo-electrical tracking function. Color film or glossing lamination can be used for package to reduce cost and upgrade products;

2)Combined molds enable the machine to be multifunctional and they can be changed conveniently. Besides, the molds consist of a chilling system;

3)Vacuum pump of Leybold is applied for high vacuum degree and stable and reliable quality;

4)Corner scrap winding and recycling system is more energy-saving than wasting film recycling bin, generates no noise and protects environment;

5)Leading horizontal and vertical cutting system is applied.

4.Main materials

1)Main parts of the equipment is made of high-strength 6061 aluminum and machine body of stainless steel;

2)High-quality copper alloy and high-strength engineering plastics.

5.Leading technologies

1)Lifting system is advanced from domestic simple lifting system to four-linkage lifting system with performance being more reliable. This system features stable operation, strong balance and low error rate and is ahead of other similar technologies.

2)Heat sealing and forming stations are multi-layer. Exclusive intelligent heating and distribution technology enables heating plate to heat faster and temperature to be distributed more uniformly. Due to application of leading chilling system inside the stations, the surface of stations will not be overheated like other similar machines. Therefore, burning caused by mistaken operation can be effectively avoided.

3)Film pre-tensing system is controlled by advanced automatic pre-tensing program, which can prevent packing film from being slack so that unqualified packages will not appear. Besides, automatic stretch function can save packing film effectively to reduce cost.

4)Recycling system is controlled by exclusive automatic scrap recycling function based on scrap length in order to effectively save electricity.

5)Advanced horizontal and vertical cutters is of beautiful appearance, safe performance and convenient maintenance. Products can be cut according to their own shape, which benefits reasonable technique arrangement.

6)Leading electrical control system integrates all control systems perfectly. The exclusive control and operation system thus formed greatly improves system performance.

6.Features

1)Fully automatic control of industrial computer on temperature, time and vacuum pressure of forming and heating sealing;

2)Intelligent safety prevention;

3)Intelligent color film and glossing lamination distinguishing;

4)Working stations of stable lifting and micron accurate positioning;

5)Intelligent wasting corner film collection;

7.Main technical parameters

| Item | Parameters |

| Overall dimensions of machine | 3300*920*1650mm |

| Upper/lower film width | 298mm/322mm |

| Temperature for forming/heat sealing | 70-130°C/125-150°C |

| Pressure for forming/heat sealing | 0.15MPa/0.15-0.3MPa |

| Forming time | 1-3s |

| Heat sealing time | 1-5s |

| Traction frequency | 2-6 times/min |

| Power supply & total power | 380V, 50Hz, 12KW (max.) |

| Requirement to chilling water | Content of chloride ion is not higher than 25mg/L |

| Pressure of compressed air | ≥0.6 Mpa |

| Pressure of chilling water | ≥0.1 Mpa |

| Machine weight | About 1000Kg |

8.Auxiliary equipment (supplied by clients themselves)

| Items | Requirements |

| Air compressor | 1.0m3/min;Pressure:10Kg |

| Air tank | 1.0m3/min;Pressure:10Kg |

| chilling water | Pressure: 0.05MPa |

| Power supply | 380V, 50Hz, 30KW |

Our Services

Service 3: We will dispatch engineers to your site for machine installation and commissioning, and also do the training for your technicians.

Service 4: We makes guarantee of the machine for 12 (twelve) months. During this Warranty period, the seller will provide free spare parts that cause by the machine’s quality within 10 days by fast courier upon receipt of buyer’s notice.(we will also provide one set of spare parts /wear &tear parts to customer along with the shipment of the machine.

Service 5: We warmly welcome the suggestions from customer to make us grow better and produce better machine along with providing better service to customer, and create more value for customer.

Service 6: Before placing the order or before shipping, welcome to our factory to take a visit to inspect our machine. we will pick you up in the airport or train station and arrange your following schedule in our city to bring you a nice journey during this visit.

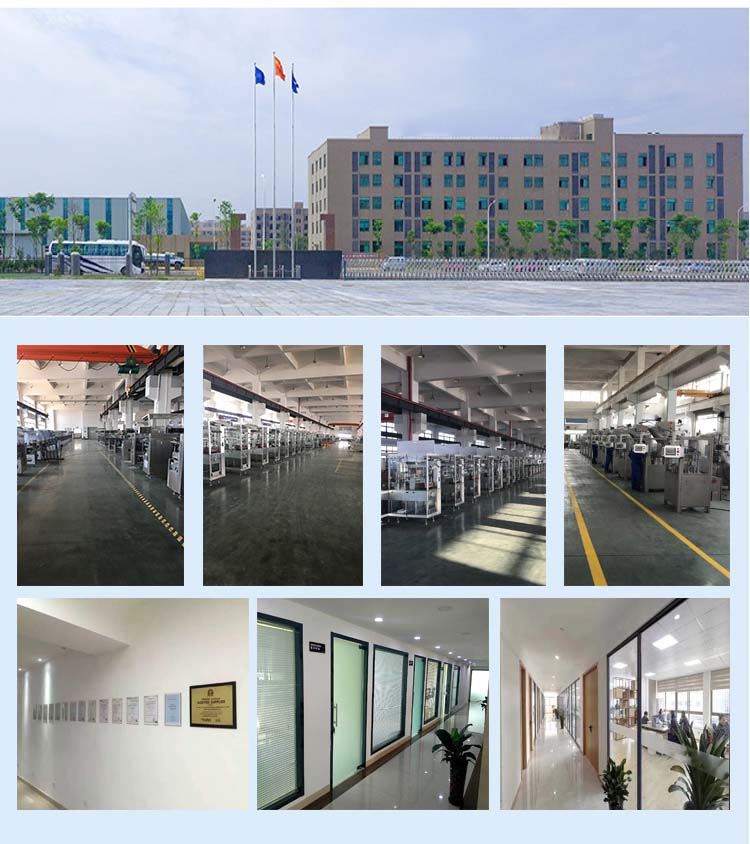

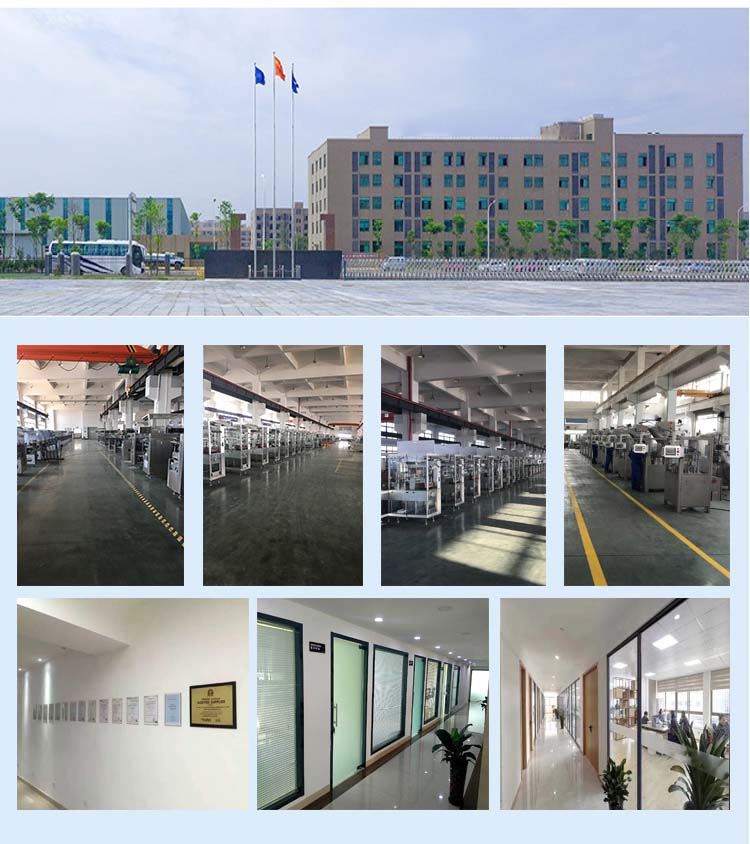

Company Information

ABOUT US

Hunan Grand Packing Machinery Co.,Ltd is specialized in the pharmaceutical and packing machinery for more than 10 years, such as plastic ampoule forming filling and sealing machine, capsule filling machine, blister packing machine, strip packaging machine, cartoning machine etc. We have provided services and machines to many different countries and regions in the whole world, such as Indonesia, Thailand, Malaysia, Philippines, New Zealand, Korea,the Middle East area, Poland, Belgium, France, UK, Greece, Italy, Turkey, USA, central and south America such as Trinidad and Tobago,Mexico, Brazil, Russia, Ukraine, UZ, Tunisia, Algeria, Morroco etc. And we always gain the good reputation from customer both from the machine quality and after sales service.

customer visit at our factory and our visit to customer

Our factory

We are cooperating with various kinds of factories and companies in different fields, including pharmaceutical factory, food factory, supplement factory, agrochemical factory such as for pesticide, fertilizer, personal care product factory, such as for cosmetic product, daily use product, stationery factory, hardware factory etc.

English

English