1. Brief introduction

1) Equipment introduction

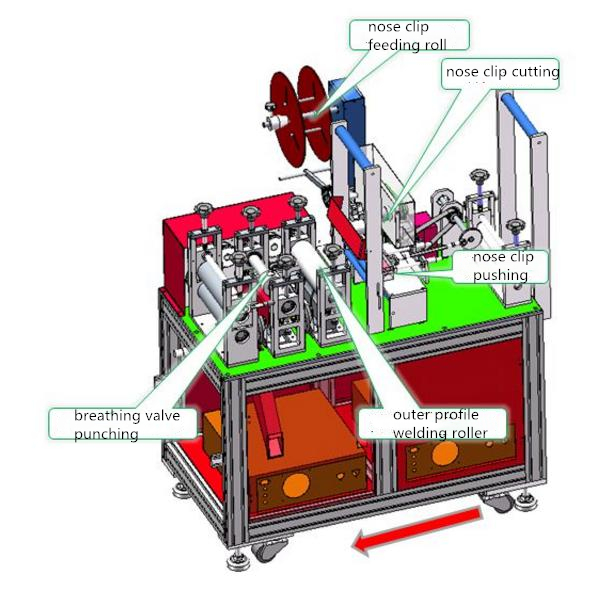

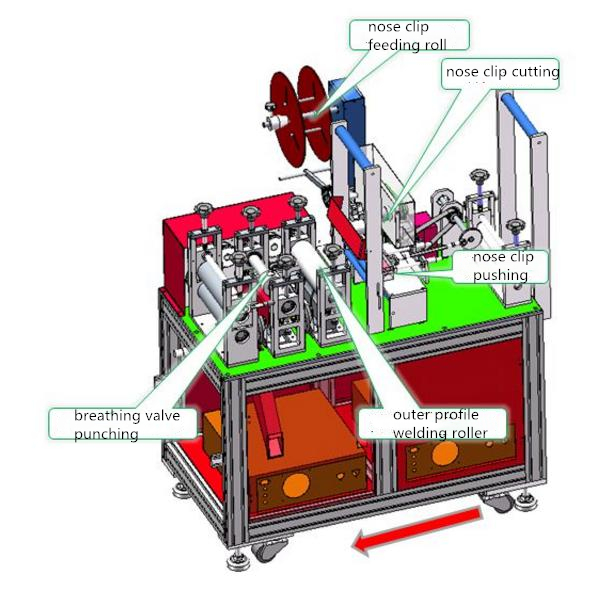

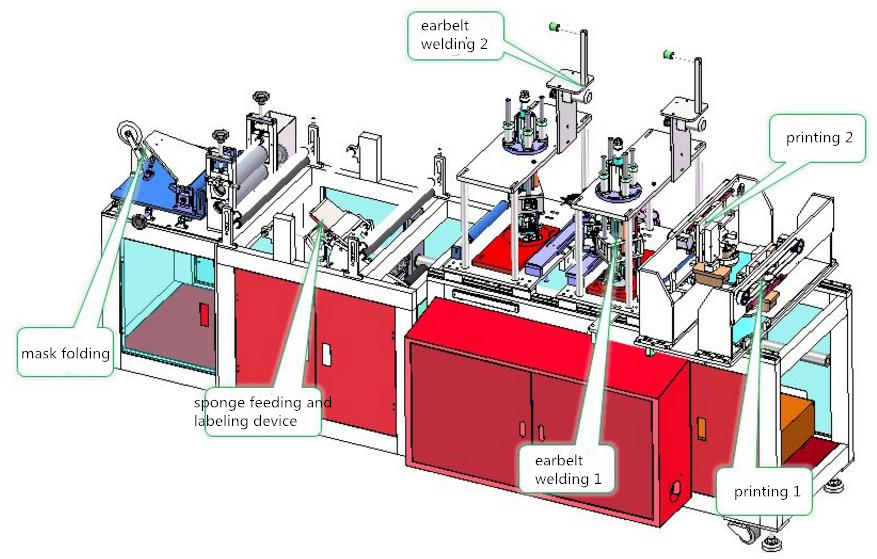

This machine can be used for automatic forming of folded N95 mask. After release, a roll of cloth material is folded together through rollers. The machine can fold cloth material, release nose clip roll, cut clip in certain length, insert clip into cloth edge, ultrasonic weld and seal double edge of mask and then punch mask with cutter.

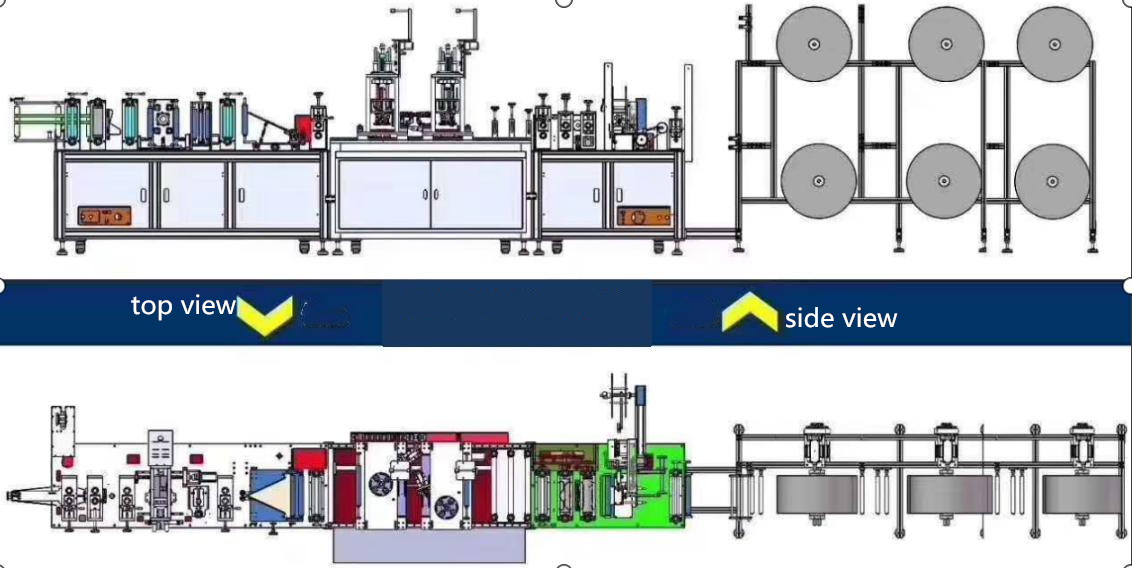

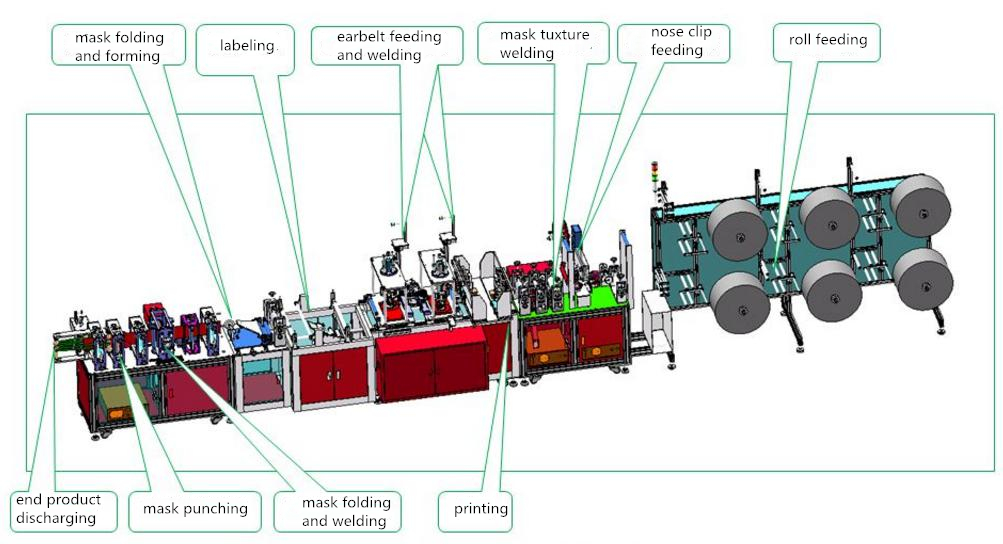

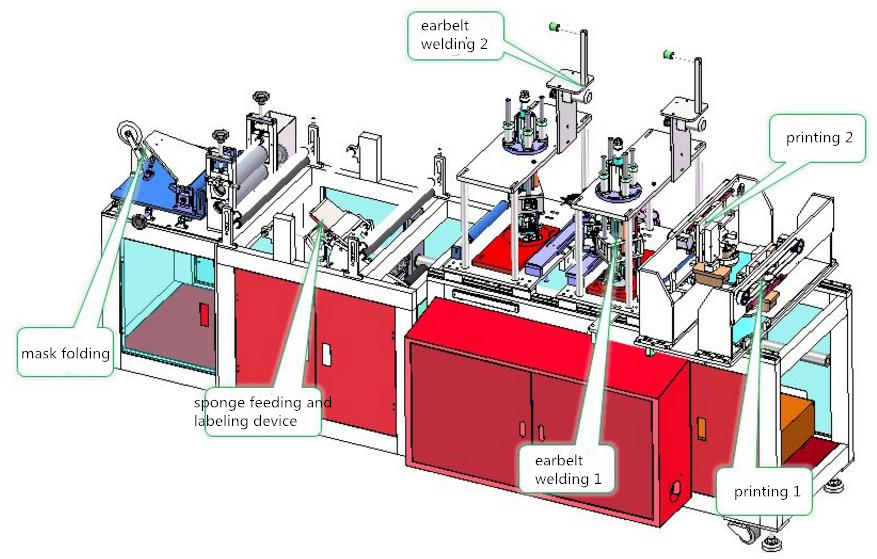

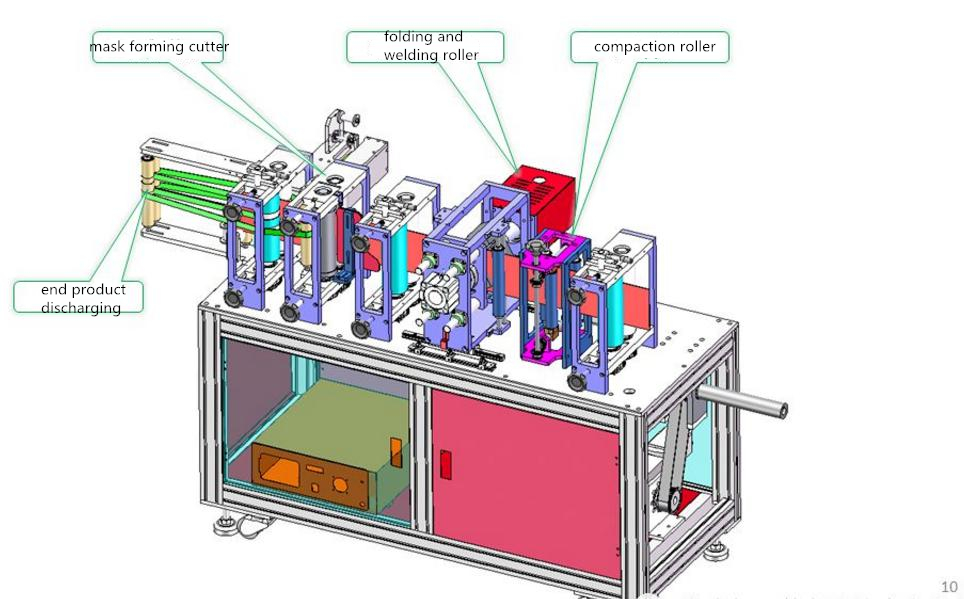

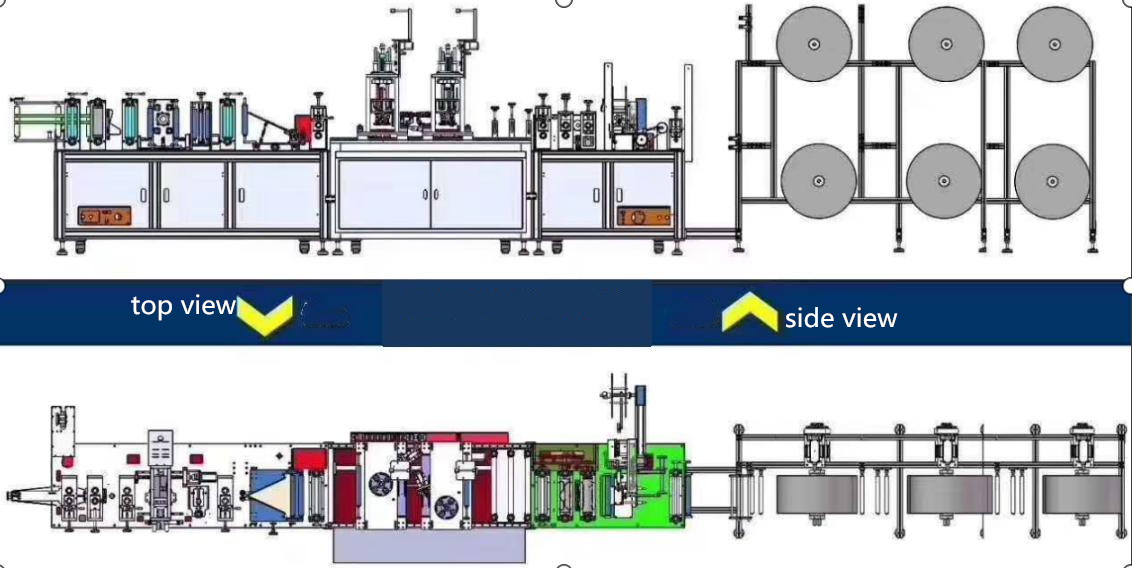

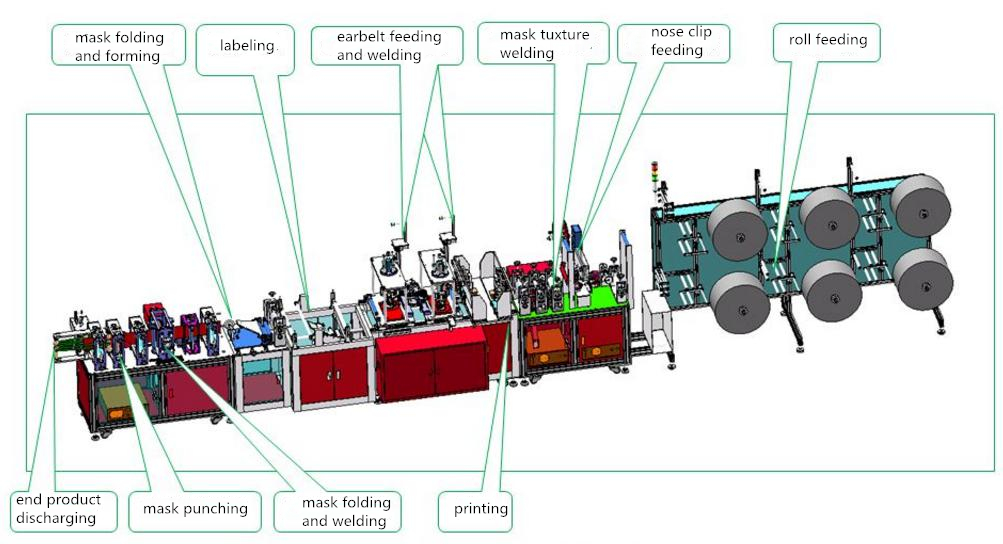

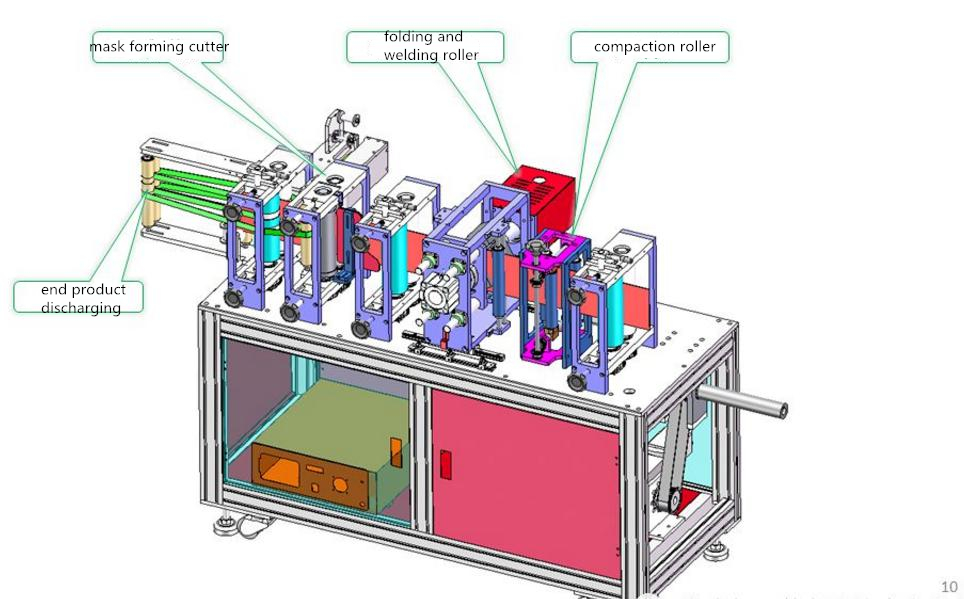

2) Overall outline design (for reference)

3) Equipment structure

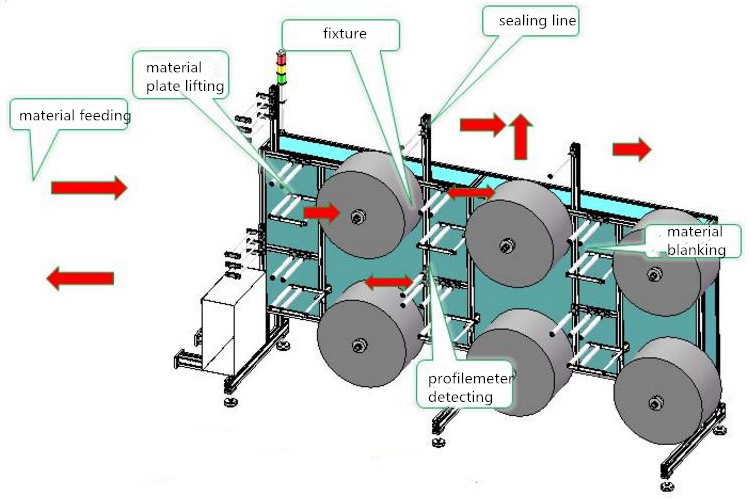

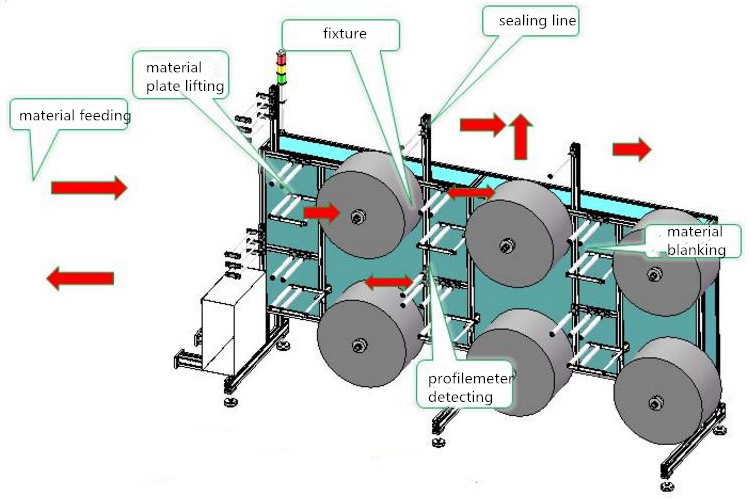

4) Flow chart

a. Material is fed onto belt of feeding device with manual trolley;

b. The belt drives the whole material plate to material plate lifting mechanism;

c. Gantry material placing mechanism can place products onto fixture;

d. The table drives fixture to the detecting station;

e. After detection, material will be fed accordingly; if OK, material is placed on the sealing line, while NG material is placed into NG channel and collected then.

5) Equipment parameters

Overall dimensions | 9700*2000*1985mm (L*W*H) |

Equipment color | International standard warm gray 1C |

Equipment weight | ≤3000KG |

Ground bearing | ≤500KG/m2 |

Power supply | 220VAC±5%,50HZ, 5KW |

Compressed air | 0.5-0.7MPa |

Air flow | 300L/min |

Working conditions | Temperature (10-35°C), humidity (5-35%), no combustible and corrosive gas and no dust (cleanness is no less than 100,000 grade) |

2. Main configuration

No. | Name | Qty |

1 | Cloth placing rack | 6 sets |

2 | Nose clip inserting and embossing station | 2 sets |

3 | Earbelt feeding and welding structure | 1 set |

4 | Mask folding and forming structure | 1 set |

5 | Mask folding and welding structure | 1 set |

6 | Mask punching and waste processing structure | 1 set |

7 | Material feeding structure | 1 set |

8 | Operation system | 1 set |

9 | Operation panel | 1 set |

3. Proper material

1) Material specification

Item | Cloth | Nose clip | Earbelt |

Qty of hanging shaft (pc) | 6 | 2 | 4 |

Width (mm) | 240-250 | 3-7 | 3 |

Outer diameter of roller (mm) | 600 | 400 | / |

Inner diameter of roller (mm) | 70 | 70 | / |

Max. weight (Kg) | 15 | 25 | / |

2) Product specification

4. Technical features

1) Automatic counting for effective production efficiency and speed control;

2) Frequency control of operation speed according to practical needs;

3) High automation and low requirements on operators. They only need to feed material and end sort product;

4) Modular and human-friendly design makes maintenance more conveniently;

Production efficiency | 35-50pcs/min |

Pass rate | 99% (except problems caused by improper material or operation) |

Equipment error rate (errors of the machine itself) | 2% |

5. Equipment configuration

1) Component list

No. | Item | Brand |

1 | Cylinder | AIRTAC |

2 | Electromagnetic valve | AIRTAC |

3 | Servo motor | XINJE |

4 | PLC | XINJE/OMRON |

5 | Bearing | HAWALUO |

6 | Linear guide | HIWIN/ABBA |

7 | Optical fiber amplifier | PANASONIC/OMRON |

8 | Touch screen | XINJE/WEINVIEW |

9 | Relay | XINJE/OMRON |

10 | Button | XINJE/SCHNEIDER/CHNT |

2) Specification part and spare part list

No. | Name | Specification | Qty | Remark |

1 | Tool box | / | 1 set | Testing tools |

6. Notes

1) Please use spare parts and materials of proper specification in order to guarantee equipment performance;

Please switch off the machine and cover cutter and the raised before maintenance and error clearing when operators need to touch devices with their hands.

7. Sample

Our Services

Service 3: We will dispatch engineers to your site for machine installation and commissioning, and also do the training for your technicians.

Service 4: We makes guarantee of the machine for 12 (twelve) months. During this Warranty period, the seller will provide free spare parts that cause by the machine’s quality within 10 days by fast courier upon receipt of buyer’s notice.(we will also provide one set of spare parts /wear &tear parts to customer along with the shipment of the machine.

Service 5: We warmly welcome the suggestions from customer to make us grow better and produce better machine along with providing better service to customer, and create more value for customer.

Service 6: Before placing the order or before shipping, welcome to our factory to take a visit to inspect our machine. we will pick you up in the airport or train station and arrange your following schedule in our city to bring you a nice journey during this visit.

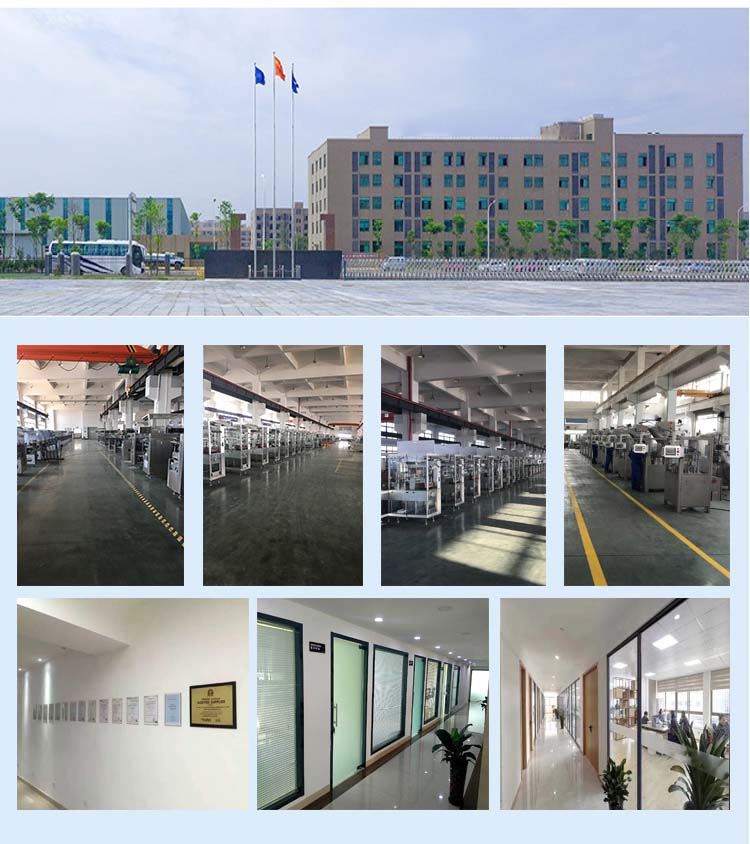

Company Information

ABOUT US

Hunan Grand Packing Machinery Co.,Ltd is specialized in the pharmaceutical and packing machinery for more than 10 years, such as plastic ampoule forming filling and sealing machine, capsule filling machine, blister packing machine, strip packaging machine, cartoning machine etc. We have provided services and machines to many different countries and regions in the whole world, such as Indonesia, Thailand, Malaysia, Philippines, New Zealand, Korea,the Middle East area, Poland, Belgium, France, UK, Greece, Italy, Turkey, USA, central and south America such as Trinidad and Tobago,Mexico, Brazil, Russia, Ukraine, UZ, Tunisia, Algeria, Morroco etc. And we always gain the good reputation from customer both from the machine quality and after sales service.

customer visit at our factory and our visit to customer

Our factory

We are cooperating with various kinds of factories and companies in different fields, including pharmaceutical factory, food factory, supplement factory, agrochemical factory such as for pesticide, fertilizer, personal care product factory, such as for cosmetic product, daily use product, stationery factory, hardware factory etc.

English

English