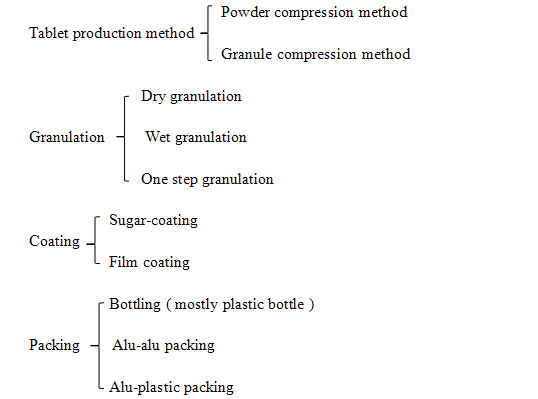

Tablet

The tablet is a round slice or special shape slice preparation which is formed by the compression of medicinal material extract, the mixture of medicinal material extract and medicinal powder, or the mixture of medicinal powder and appropriate excipient.

Type: Ordinary compressed tablets, coated tablets, sugar-coated tablets, film-coated tablets, enteric coated tablets, effervescent tablets, chewable tablets, multilayer tablets, dispersible tablets, sublingual tablets, buccal tablets, implant tablets, solution tablets, sustained release tablets.

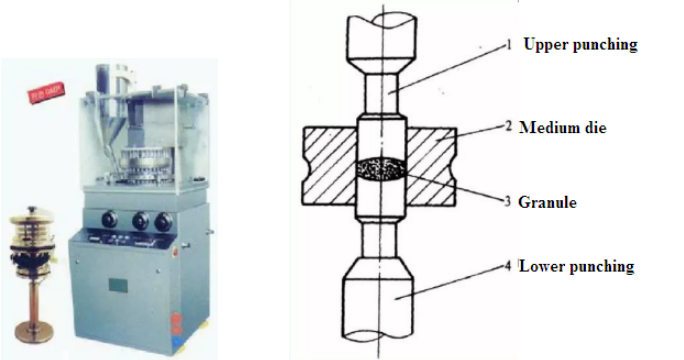

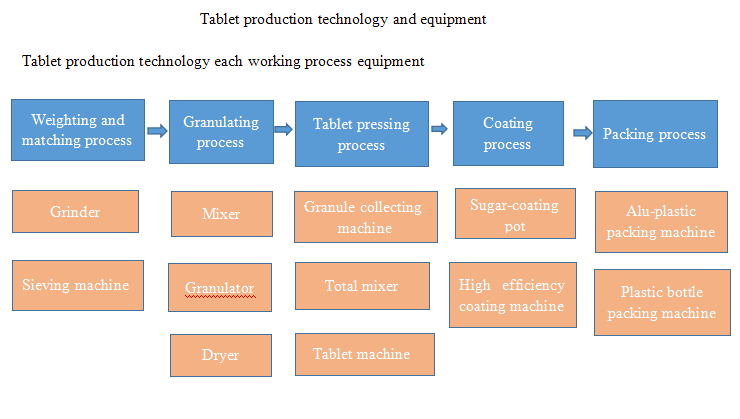

Tablet machine basic structurec

It consists of punching die device, material feeding device, filling device, pressing device and tablet output device.

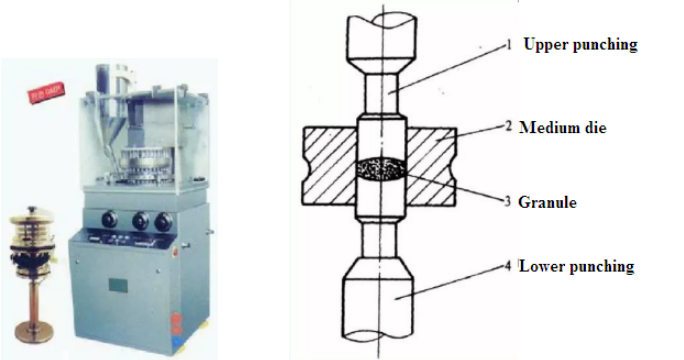

(1) Punching die

It consists of upper punching head, lower punching head and medium die.

The shape of punching head and mould hole can be figure, and it can be special shape like triangle.

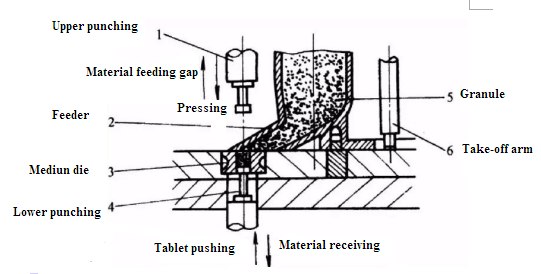

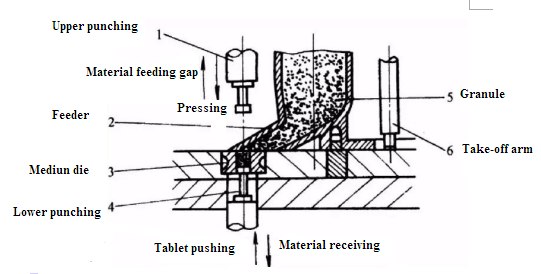

(2) Material feeding

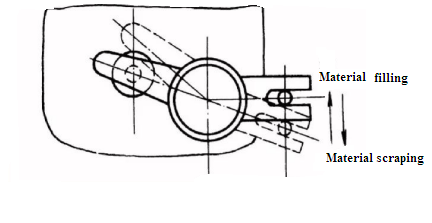

Boot-shaped feeder: 1. Upper punching 2. Feeder 3. Medium die 4. Lower punching 5. Granule 6. Take-off arm

It is used for single punching or flower basket tablet machine. The feeder is used for filling and scraping material, and the mould hole is motionless for waiting for the material.

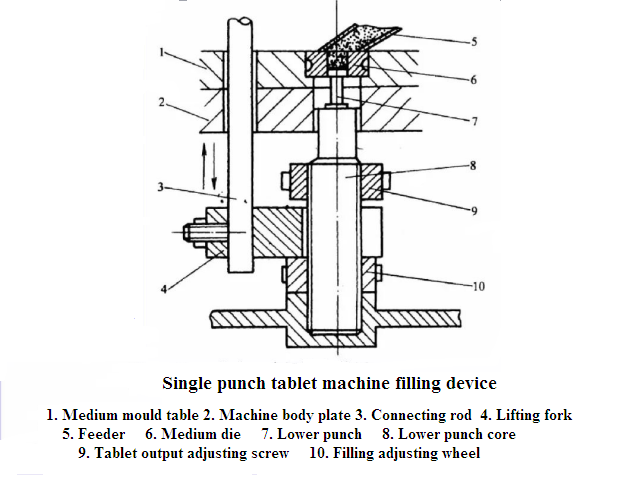

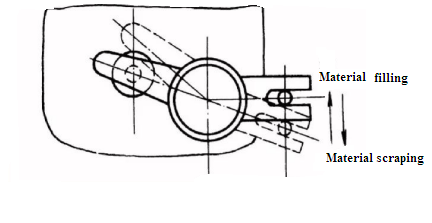

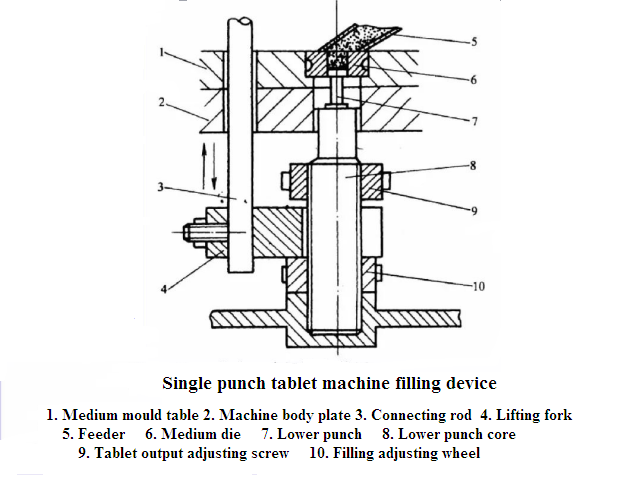

(3) Filling

The volume of the mould hole is changed by adjusting the position of the lower punch head to control the quantity of the filled granule.

Single punch tablet machine: adjust the screw directly to lift or lower the punch, thereby change the volume of the mould hole.

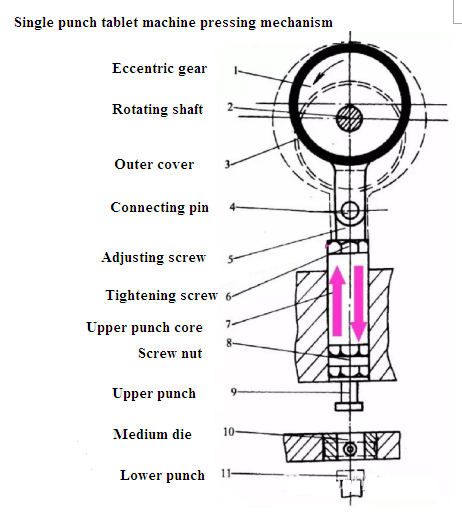

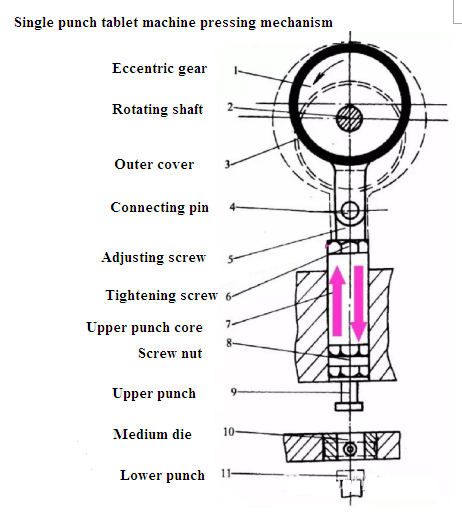

(4) Pressing

The quantitative granule is machine-pressed to the tablet with a certain of thickness and rigidity by taking advantage of the relative position of upper punch and lower punch.

There are two types of pressing mechanism, which are the crank impacting type and the positioning wheel-pressing type.

Screw the tightening screw to adjust the upper punch core: right screwing for smaller pressure and tablet thickness, and left screwing for larger pressure and tablet thickness.

(5) Tablet output

The tablet output mechanism is used to push out the tablet pressed to forming inside the medium mould hole.

Whatever tablet machine the mechanism is, its principle is to lift the lower punch to push the tablet out of the medium mould.

For the single punch tablet machine, the screw 9 can be adjusted to lift the lower punch to the position, which is in alignment with the medium mould.

Quality testing

lThe quality should meet: ① moderate rigidity ② uniform color and clean appearance ③ weight difference requirement and accurate content ④ disintegration and dissolution requirement ⑤ content uniformity requirement for small dose medicine or medicine with acute effect ⑥ relevant sanitary requirement

lThe unqualified waste tablet should be rejected.

Pill

The pill is a sphere or spheroid preparation which is formed by medicinal material powder, the mixture of medicinal material extract and appropriate adhesive, or other auxiliary material. It is classified as honeyed pill, watered pill, water-honeyed pill, starched pill, condensed pill, wax pill, and pellet.

Auxiliary material: wetting agent, adhesive, and absorbent.

Pill: It is a sphere and spheroid solid preparation which is made by appropriate method after mixing uniformly the medicine and appropriate auxiliary material.

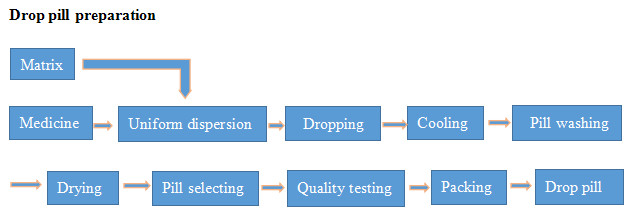

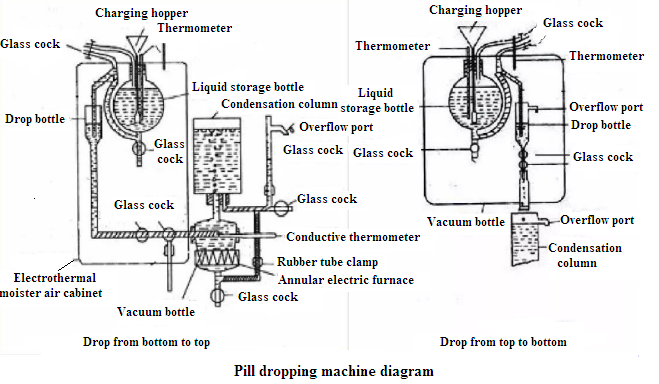

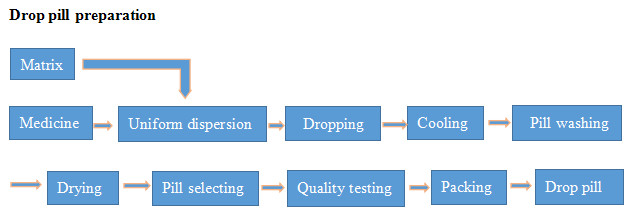

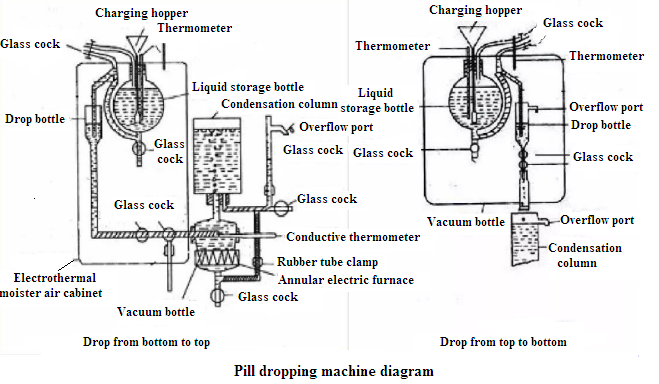

lDrop pill: Heat and melt the solid, or the liquid medicine and appropriate matrix, dissolve, emulsify, or suspend them in the matrix, then drop them in the immiscible and compatible condensate. The liquid drop is condensed to the sphere preparation due to surface tension effect.

lSugared pill

lPallet

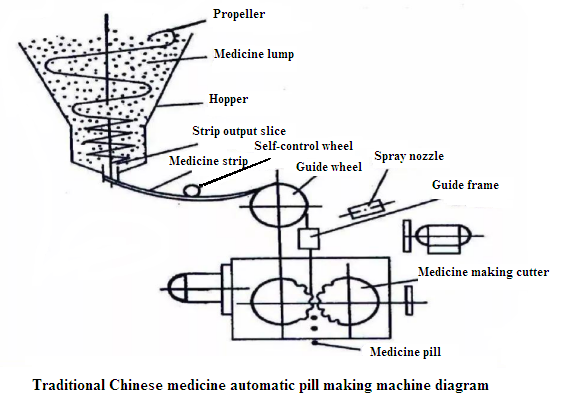

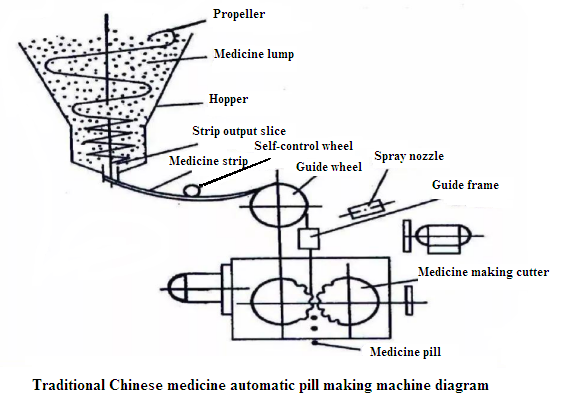

lTraditional Chinese medicine pill preparation

lPlastic preparation method technological process

Medicine powder + auxiliary material → pill mass making → pill strip making → cutting and rubbing circle → quality testing → packing

lGeneral preparation method technological process

Medicine powder + auxiliary material → drawing → forming → capping → drying → pill selecting → coating → quality testing → packing

lTraditional Chinese medicine pill quality testing

lMoisture

lWeight difference

lDissolution time limit

Drop pill

Overview

ØCommonly used matrix

lWater soluble matrix: polyethylene glycol, polyoxyethylene monostearate, sodium stearate, poloxamer, etc.

lNon water soluble matrix: stearic acid, glyceryl monostearate, hydrogenated vegetable oil, stearyl alcohol, etc.

ØCondensate

lWater soluble condensate: water and ethyl alcohol with different concentration, which are suitable for non water soluble matrix drop pill.

lNon water soluble condensate: Liquid paraffin, dimethicone, vegetable oil, gasoline or the mixture, which are suitable for water soluble matrix drop pill.

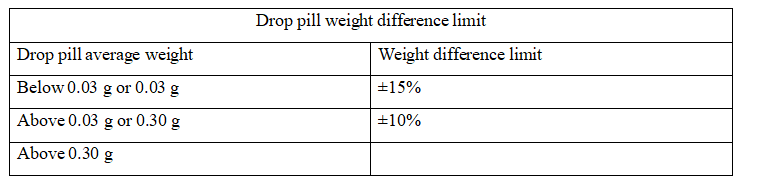

Drop pill quality testing

ØAppearance: uniform size and color, no adhesion phenomenon, and no adhesive condensate in the surface.

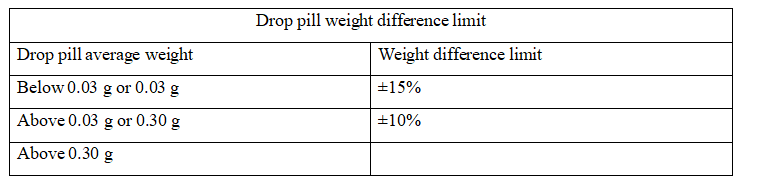

ØWeight difference

ØDissolution time limit

Capsule

Overview

The capsule is a solid preparation which is made by packing the medicine into the hollow hard capsule or sealing it into the elastic soft capsule.

Capsule feature

(1) It can hide the bad smell of the medicine, and improve medicine stability.

(2) The medicine can have a quick effect inside the body.

(3) Solid dosage form of liquid medicine.

(4) It can delay medicine release and release the medicine at the special position.

Capsule classification

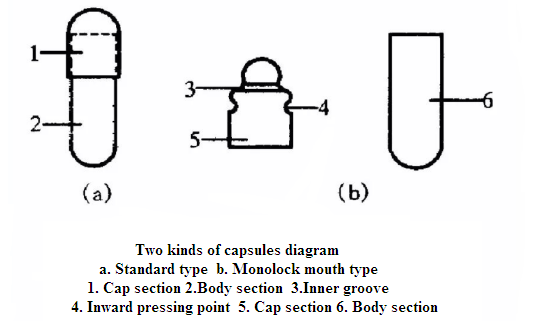

(1) Hard capsule: A certain amount of medicine and appropriate amount of auxiliary material (the auxiliary material is not necessary) are made into uniform powder or granule, and they are filled into the hollow hard capsule, then the hard capsule is made. The hard capsule is cylindrical, and it is made up of two packed boxes. Its size is represented by the number, and chosen for usage according to medicine dosage.

(2) Soft capsule: It is a circular and oval-shaped preparation which is made by dissolving a certain amount of medicine ( medicine extract ) in the appropriate liquid auxiliary material, and sealing them into the soft capsule. As per different preparation methods, the soft capsule is classified into the seam soft capsule and the seamless soft capsule. The former adopts the compression method for production, and there is a seam in the middle of the capsule; the latter adopts the dropping method for production, and it is spheroidal and seamless.

In addition, as per the application, it can be named as enteric capsule, colon-targeted capsule,etc.

The capsule is mainly used for oral administration, but in the recent years, it also is used for orifice administration such as rectum, and its usage is similar to the suppository.

Hard capsule preparation

The hard capsule preparation usually includes empty capsule preparation, filling material preparation, filling, sealing and other technical processes.

Empty capsule preparation

(1) Empty capsule composition

The gelatin is main encapsulation material of empty capsule, and it is made by hydrolyzing bone and fur.

The gelatin made by acid hydrolysis is called as A type gelatin, and its isoelectric point is PH 7~9.

The gelatin made by alkaline hydrolysis is called as B type gelatin, and its isoelectric point is PH 4.7~5.2.

The auxiliary materials which need to be added when preparing the empty capsule

① Plasticiser ( increase tenacity and plasticity )

② Thickener ( decrease fluidity )

③ Opacifier ( suitable for photosensitive medicine )

④ Colorant ( beautiful and easy to discern )

⑤ Preservative ( to prevent from mildew )

Not each kind of empty capsule must contain above all components, and they should be selected as per specific conditions.

Empty capsule preparation technical process

Gelatin melting → Gelatin dipping ( embryo making ) → Drying → Shell pushing → Cutting → Collecting → Sifting

The production environment should reach 10000 grade, the temperature should be 10~25℃, and the RH should be 35%~45%.

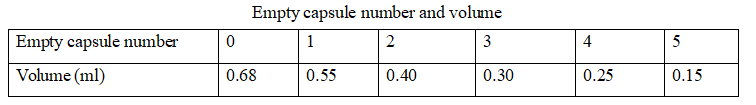

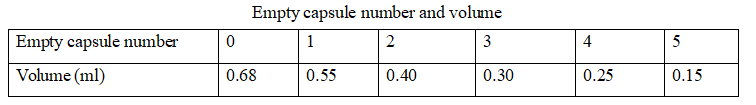

(2) The empty capsule specification are divided into eight kinds in descending order, which are No.000, No.00, No.0, No.1, No.2, No.3, No.4 and No.5. Generally, N0.0~No.5 are used commonly.

Medicine material filling and sealing

1. Capsule specification selection

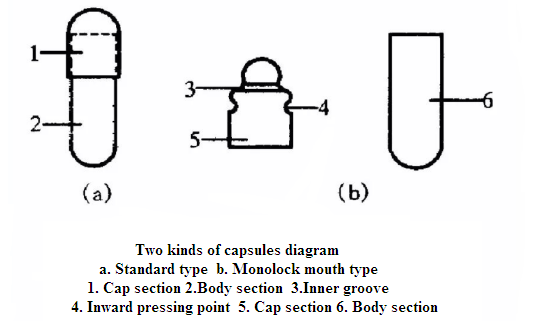

Empty capsule selection The empty capsule is divided into standard capsule and lock mouth capsule ( there are monolock mouth type and double lock mouth type ). At present, the lock mouth type capsule is used more frequently due to its good sealing.

2. Medicine filling

①If the pure medicine ground into appropriate granule size can meet the filling requirement of the hard capsule, it can be filled directly.

②If the medicine has poor fluidity, a certain amount of auxiliary material such as diluent and lubricant needs to be added.

3. Sealing

Soft capsule preparation

·The capsule shell of the soft capsule consists of gelatin, plasticiser and water, and their weight proportion usually is that dry gelatin : dry plasticiser : water=1 : 0.4~0.6 : 1.(Commonly used plasticity is glycerinum, sorbital or their mixture.)

·The capsule wall of the soft capsule has plasticity and elasticity, which is the feature of the soft capsule and the foundation of its existence.

English

English