1. Definition--what is spunlace non woven fabric

High-pressure micro flow is ejected to the fiber web of superfine fiber non-woven fabric so that the fibers entwine with each other and the fiber web can be more reinforced. Such reinforced fabric is namely spunlace non-woven fabric.

Normally, spunlace non-woven fabric can be made from polyester, nylon, polypropylene, viscose fiber, chitin fiber, superfine fiber, tencel, silk, bamboo fiber, wood pulp fiber, seaweed fiber and so on.

Weight | 45-120g/m2 |

Width | Depending on customer’s needs |

Raw material | 99% viscose/99% polyester fiber/70% viscose and 30% polyester fiber/50% viscose and polyester fiber/80% polyester fiber and 20% viscose (more viscose, more expensive) |

Color | Red, yellow, blue, green, white... |

Processing way | Netting and spunlacing |

Lines | Plain, mesh, emboss, rhombic, wavy or pearl |

Application | Gauze, bandage, bath towel, wet wipe, soft wipe, cosmetic cotton, facial mask, rag and so on |

2. Main raw material for spunlace non woven fabric

1) Natural fiber: cotton, wool, hemp and silk;

2) Regular fiber: viscose fiber, polyester fiber, acetate fiber, polypropylene fiber, polyamide fiber;

3) Differential fiber: superfine fiber, profiled fiber, low melting point fiber, high crimp fiber, anti static electricity fiber;

4) Highly functional fiber: aromatic polyamide fiber, carbon fiber, metal fiber.

3. Processing principle for spunlace non woven fabric

The principle for spunlace non-woven fabric reinforcing is similar to needle-punching technology. But there is no need for spunlace non-woven fabric to be needle-punched since it is produced by ejecting micro flow at high pressure.

The flow is ejected through the fiber web and it can make the fiber web entwine. As a result, the fibers are pushed by the flow to displace, cross and entangle and then reinforced.

Crossing: the non-woven can have pretty good vertical and horizontal strength and thus is tougher and more expensive.

Lining: the non-woven is tougher vertically than horizontally and is cheaper.

If the weight of non-woven fabric is larger than 50g/m2, it is estimated that the crossing fabric cannot be torn while the lining fabric can be torn horizontally. If there is no requirement on toughness, the lining fabric can be a better choice.

4. Features

1) The fibers entwine with each other by spunlacing. They will not be damaged and can keep soft. Therefore, the spunlace non-woven fabric is both tough and soft;

2) Spunlace non-woven fabric looks like traditional fabric but different from other non-woven fabric since it is more natural and softer;

3) Spunlace non-woven fabric is so tough that it is pretty resistant to wear and doesn’t pill. No adhesive is added during production and the toughness comes totally from the fibers so that the fabric will not soften as being washed for many times;

4) Spunlace non-woven fabric can absorb moisture into the fiber web quickly. It is also draughty and the clothes made from it can prevent the wearer from feeling stuffy;

5) The appearance of spunlace non-woven fabric can be designed for different aesthetic demands;

6) However, spunlace non-woven fabric production is also featured by long production process, large covering space, complex equipment, high requirement on water and huge energy consumption.

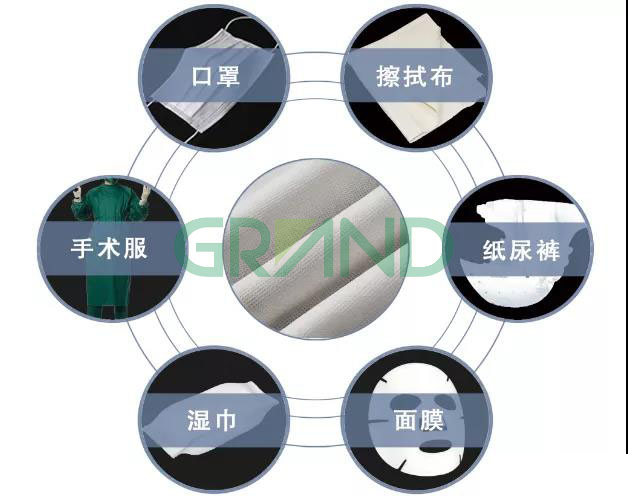

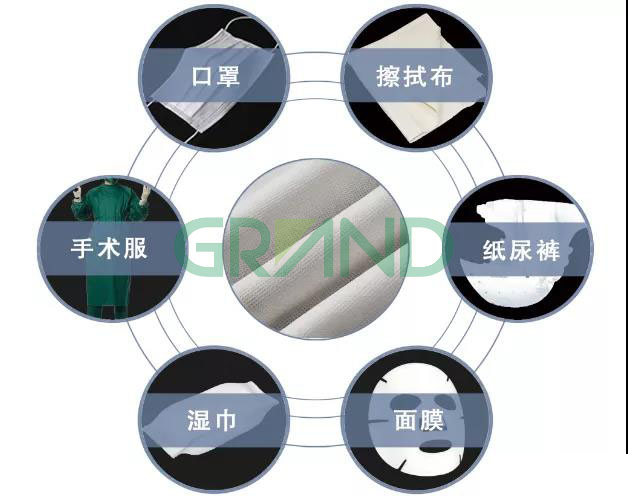

5. Application for spunlace non woven fabric

Spunlace non-woven fabric is widely used in medical industry, cloth industry, building industry and household.

1) Medical non-woven: surgical clothing, protective clothing, disinfection cloth, medical curtain, wound dressing, wet tissue and wipes( such as alcohol pad, sterilization wet tissue , baby wipes) Please check the spunlace non woven fabric used on our wet tissue packing machine.

4) Sanitary cloth: wet wipe, magic towel, cotton pad, soft towel roll, beauty products, sanitary napkin, sanitary pad and disposable sanitary cloth, face mask, diaper, rag...

5) Household: wall cloth, table cloth, bed sheet and bedspread...

6) Cloth: lining, adhesive lining, batting, setting cotton, all kinds of synthetic leather backing...

7) Industrial non-woven: filtering material, insulation material, coating base cloth, cement packing bag, geotextile, covering cloth...

8) Agriculture: crop protection cloth, seedling raising cloth, irrigation cloth, thermal insulation curtain...

9) Others: electronic high-grade dishcloth, instrument high-grade dishcloth, aviation dishcloth, space cotton, heat and sound insulation materials, oil felt, cigarette filter, tea bag...

6. Production situation in China

1) Production line

Spunlace non-woven fabric production line develops rapidly in China, especially in Jiangsu province and Zhejiang province. Instead of being influence by economic crisis, spunlace non-woven industry bucks the trend and has introduced more and more production lines.

2) Production technology

The spunlace non-woven fabric production technology develops toward being high-speed, high-quality and roller-spunlacing. And now the main limiting factor of spunlace technology development is lack of high-speed, high-output and high-quality carding machines.

It is still incapable for manufacturers in China to manufacture roller spunlacing machine. And there is lack of web laying machines whose practical laying speed can reach 70-100m/min. In addition, the experience of spunlacing machine manufacturers in USA, France and Germany is rarely introduced into China so that it’s hard for manufacturers in China emulate their strong points.

3) Scientific research development

It has cost nearly 10 years for spunlace non-woven fabric research, development and production. Obvious progress in variety, scale, quality and equipment has been made and needs of national economic development has been basically met.

Besides, spunlace non-woven fabric is closely related to medical industry, light industry, electronics, environment and some other subjects. Its development also pushes that of traditional chemical fiber and differential fiber.

English

English