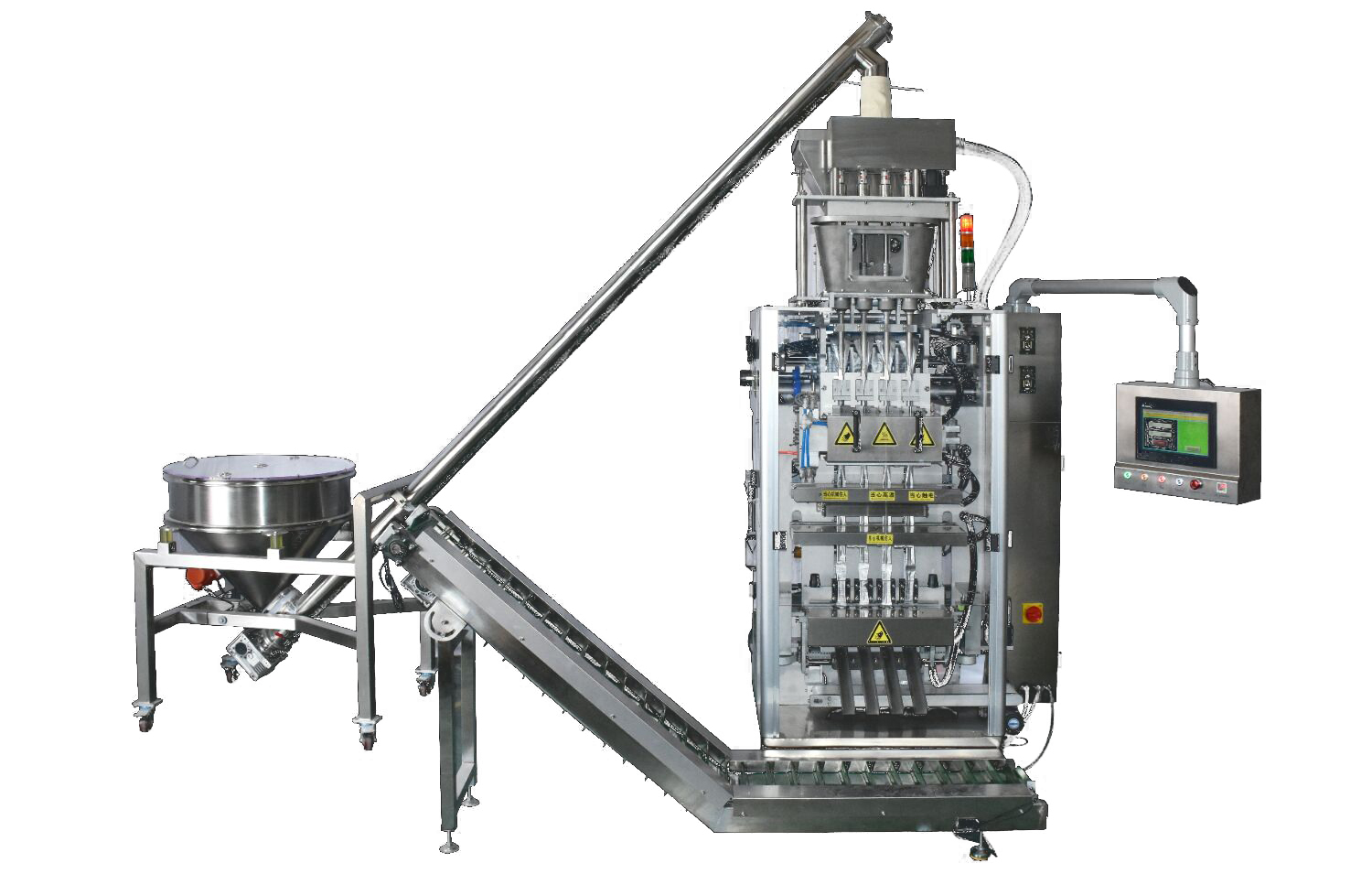

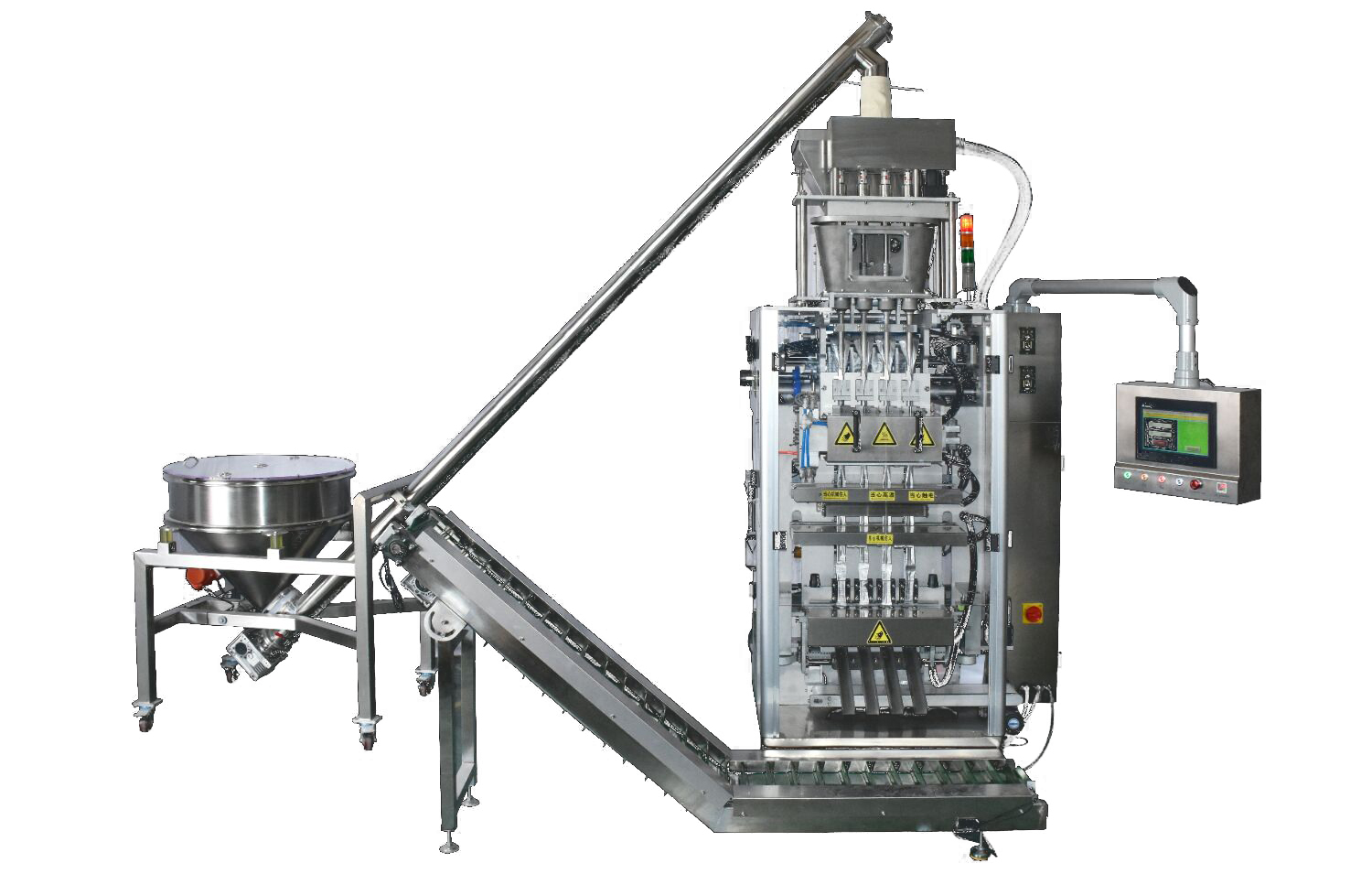

Packing function

Double-side color mark for automatic correction, and automatic tracking for adjustment. It can automatically complete the packing process such as sachet making, metering, filling, sealing, punching, easy tearing notch cutting, horizontal and vertical easy tearing break line cutting, batch printing, and counting. The automatic multi-sachet packing of packed product can be finished in one-time filling.

Packing range

It is suitable for packing materials with different shapes such as powder, tablet, capsule, granule, pill, and viscous material.

Sachet size range | Sachet length:55-180mm; Sachet width:32.5-420mm (Min.width of powder sachet is 60 mm.) |

Metering range | 1-200ml (0.5-100g) |

Sachet line number | 2-12 lines (Liquid packing usually is more than 10 lines) |

Horizontal cutting frequency (time/min) | The highest frequency is 70 times/min, and stepless (setting) adjustment can be performed according to usage requirement. (The highest speed for powder is 40 times/min.) |

Max.width of packing material | 910mm |

Appropriate packing material | Plastic/Aluminum/Plastic, Plastic/Paper/Plastic, Plastic/Plastic, Plastic/Aluminized/ Plastic |

Metering precision | ±5% |

Power supply | 380V 50Hz |

Total power | 7.5 kw |

Noise

| 76 dB(A) |

Appropriate environment temperature | 0℃-35℃ |

Appropriate altitude | <2000 m |

Overall dimension (L*W*H) | 1500*1540*2200 mm |

Weight | 1200 kg |

Motor frequency | 5-60Hz (Motor rotating speed: 135-1620 r/min) |

Automatic control capacity in the production

The whole machine is controlled automatically by the computer. It adopts double-side color mark for automatic correction and automatic tracking for adjustment. The main machine adopts stepless frequency conversion for speed regulation. The heating temperature is controlled by the machine. If there is wrong operation and multi-point faults, the machine will stop running automatically.

Error adjustment capacity in the production

The packed volume of single sachet and multiple sachets can be adjusted, and it can be sure that the error is ±5%.

GMP standard compliance

"Guidelines for the Implementation of GMP in Pharmaceutical Equipment" Artical 3, Chapter 1, Section 10, "Sachet Packaging Machine" related provisions and requirements. GB/T17313-1998 “Sachet forming-Filling-Sealing Machine”

Basic configuration & structure

1. The key parts of control system adopt imported control components with reliable performance.

a. PLC: FX1N-60MR Made in Mutsubishi, Japan;

b. Frequency converter: VF015A 21A Made in Delta,Taiwan;

c. Man-machine interface: Smart700 Made in Siemens.

2. Filling system

Due to different packed products, the machine is equipped with dedicated filling and product feeding device with different forms: volumetric product feeding device for granule material, and vibrating product feeding device for tablet, capsule, and special-shaped tablet.

3. Transmission system

The machine adopts belt drive, chain drive, gear drive, cog belt drive and conveyor belt drive respectively according to detail requirements of different parts. These transmission processes are completed respectively by motor, reducer, gear, chain wheel, cog belt wheel, and drive shaft. The differential mechanism is adopted in the four places of the transmission system for special requirements such as printing, horizontal cutting, horizontal break line cutting, and automatic correction with color mark. The adjustable eccentric sprocket mechanism is adopted in the two places of the drive system, and its adjustment amount is determined by the sachet size.

4. Film unwinding

The film unwinding mechanism, located on the rear of the machine, consists of unwinding shaft, unwinding frame, film guiding roller, and movable film guiding roller. The process of the film unwinding is that the unwinding shaft is driven by the micro motor to put the film roll in motion, then the unwinding length and the film tension force are controlled through the movable film guiding roller. When the film is run out or parted suddenly, the photoelectric switch is covered by the movable film guiding roller, so that the machine will stop running automatically. The hand shank adjusting the left-right movement of the unwinding roller is placed on the left side of the film unwinding mechanism in order that the center of the film is aligned with the center of the film splitting mechanism.

5. Film splitting

The film splitting mechanism, located on the top of the machine frame, consists of film guiding roller, cutter, and film splitting plate. The film is splitted into two parts by the film splitting mechanism, then their moving direction is turned by the film splitting plate, and they are pulled to vertical sealing roller for sealing by the film guiding roller. The film splitting plate can move back and forth through the hand wheel to meet requirements of packing materials with different width.

6. Sealing: It includes vertical sealing and horizontal sealing. By it, the four-side sealing of sachet making is formed.

①The vertical sealing device is made of a couple of vertical sealing rollers, and the heater and thermosensitive elements are installed inside it. When it works, the couple of vertical sealing roller rotates continuously in the reverse direction, and the film is heated and rolled to form the vertical sealing belt under their traction. The pressure between the two rollers is offered by springs, and the two rollers can be parted manually when the operation ends.

②The horizontal sealing device is made of a couple of horizontal sealing rollers, and the heater and thermosensitive elements are installed inside it. When it works, the couple of horizontal sealing rollers are driven by the transmission system to rotate continuously through the gear in the reverse direction, and the pressure between them is offered by springs. There is 2 or 3 sealing belts around the horizontal sealing roller, therefore the sealing times is 2 or 3 with it turning a circle.The adjustable eccentric sprocket mechanism is adopted in the transmission chain to make sure that the instantaneous linear velocity when sealing horizontally is line with the linear velocity of the film, in case that the film wrinkles or is stretched too far, even broken. The sealing structure has reasonable design, and the packing material has a wide range for choosing.

7. Batch printing and easy tearing notch cutting mechanism

The batch printing mechanism and the easy tearing notch cutting mechanism are on the same shaft, while they are staggered at certain angles. Their supporting plates also are on the same shaft. When the machine works, the two shafts rotates continuously in the reverse direction. Once they turns a circle, these two operations are performed three times. The shaft has same revolving speed and linear speed with the horizontal sealing roller, and the eccentric sprocket mechanism is also adopted in the transmission chain. The operation of the batch printing device keeps pace with the the main machine. By this, the batch number is clear and firm, and easy to replace.

8. It has the functions of easy tearing notch cutting, vertical cutting, vertical easy tearing break line cutting.

The rotating cutting, in sync with main machine operation, is adopted by the easy tearing notch cutting mechanism, the vertical break line cutting mechanism and the vertical cutting mechanism, in such way that the easy tearing notch is in the right position. The vertical easy tearing break line cutter with unique design and operation structure has a longer service life.

9. It has the functions of horizontal cutting and horizontal break line cutting.

The horizontal cutter and the horizontal break line cutter are in the unique saddle-shaped curved surface motion, which has reasonable and reliable operation. The cutting of the horizontal cutter and the horizontal break line cutter can be controlled by the main computer and set on the man-machine interface. The product can be set to single sachet cutting or multiple sachets cutting.

10. Mould equipment and replacement Each main machine is equipped with a set of mould.

If the size of the packing sachet is changed in the production, then the mould needs to be changed. If the sachet size is changed and the sachet width still is unchangeable, then it just needs to replace a pair of transmission sprocket.It costs few to replace the mould. (The machine can be equipped with stepless sachet length regulator to meet costomers’ needs for different sachet length, while its price will be calculated separately.)

11. Temperature control

The machine adopts high-precision temperature controller to make sure that the error between the sealing setting temperature and the show temperature is controlled within 3℃. The heater and the sealing mould has reasonable design and passed running test. As a result, the temperature of effective sealing region is controlled precisely, the sealing of sachet making has better effects, and the packing machine has more choices in the quality and texture of packing material. The design of the sealing mould takes into consideration the thermal field of the effective sealing region, making better sealing effects and saving more energy.

12. It is equipped with photoelectric positioning system.

The machine is equipped with the photoelectric trademark positioning system.The signal is measured by the photoelectric head on the printing color mark of the packing material, and the optical fiber sends it to PLC for operation, then the micro-motor of the cursor correction differential in transmission system is driven for automatic correction and automatic traction of the double-side color mark (the four sets of the adjusting differential are installed on the machine), in order that the patterns printed on the double faces of the product are aligned with each other completely when sealing.

English

English