No effort is spared in solving the problem of plastic pollution in China. The document about further plastic pollution control has been approved. Besides, National Development and Reform Commission, together with Ministry of Ecology and Environment, released an essay, clearly claiming to extend application of degradable packing film, degradable shopping bags, bio-based products conforming to requirements on performance and safety, degradable plastic bags and some other alternative products. These alternative products are actually bioplastics.

In the following essay, the notions, features, application and prospect of these bioplastics will be introduced generally.

1. What is bioplastics

According to the definition by European Bioplastics Association and Japan Bioplastics Association, bioplastics is the collective name of bio-based plastics and biodegradable plastics. The former notion is advanced from the perspective of raw material while the latter notion from the point of view of environmental degradation performance.

Viewed from different aspects, the bioplastics can be classified into 3 types: 1) non-degradable plastics based on renewable raw materials. For example, corn starch is firstly processed to biological ethanol and then to PE, PP or PET based on the ethanol.; 2) degradable plastics based on renewable materials, such as thermoplastic starch (being of starch origin and becoming thermoplastic under the action of additives), PLA (being polymerized from lactic acid which is degraded from corn starch), Cellulose acetate (being hydroxyacetylated from plant cellulose). They are both bio-based and biodegradable; 3) biodegradable plastics based on fossil resources, including PBS (being polymerized from succinic acid and butanediol) and PCL (being condensed from 6-hydroxycaproic acid).

It can thus be seen that perhaps bio-based plastics cannot be degraded while biodegradable plastics is not always bio-based. And the bio-based plastics is not made from single material but from materials with different performances and applications.

The environmental value of bio-based plastics is always assessed on the basis of percentage of biochar. Traditional plastics derives from fossil resources (like petroleum and coal). However, the age-old fossil material contains no 14C. Therefore, 14C can be an index for biochar content measurement.

In this case, American Society for Testing and Materials built ASTMD6866 standard, which is equal to CEN/TS 16137 standard in Europe. Normally, an independent third-party certification body carries out the assessment to the bioplastic packing material and certifies the product with marks as in the following picture.

A: introduced by Vincotte, a Belgian certification body. (One star embodies 20%-40% biochar content, two stars 40%-60%, three stars 60%-80% and four stars over 80%)

B: introduced by DIN CERTCO, a German certification body.

Biodegradable plastics refers to the plastics which can be degraded under conditions of natural environment or composting. Furthermore, the compostable plastics can decompose to carbon dioxide and have no negative influence on plant growth.

There are also some standards for cmpostable plastics, such as EN13432 for European countries, ASTM D6400 for USA and ISO 17088 for other countries. Common certification marks are as the following picture shows.

A: introduced by Vincotte

B: introduced by DIN CERTCO

The main difference between bio-based plastics and fossil plastics is their constituents. Normally speaking, fossil plastics contains only elements of C and H, while bio-based plastics contains elements of C, H and O. Wide application of bio-based plastics can bring about some advantages:

1) Reduce emission of carbon dioxide and prevent greenhouse effect from being worse;

2) Reduce white pollution and save land resource from landfill.

It is estimated that over 65% bio-based plastics are used as packaging material for catering industry, electronics, automobile, gardening and toys... However, their high price limits their extensive use.

2. Application

Commercial bio-based plastics mainly includes starch plastics, PLA, PHA polymers, PBS, cellulose and so on.

1) Starch plastics

Wide origin, renewability, low cost and degradability enable starch to be widely used in starch plastics production. According to the standard of GB/T 21661-2008 of China, starch plastics refers to the plastics containing more than 15% starch.

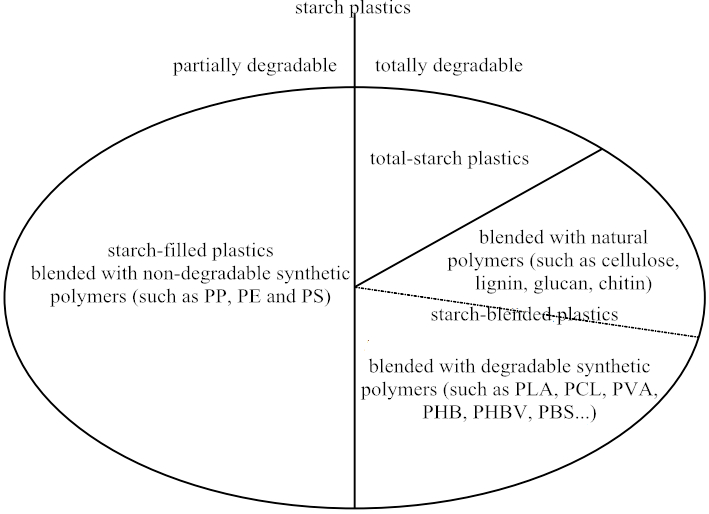

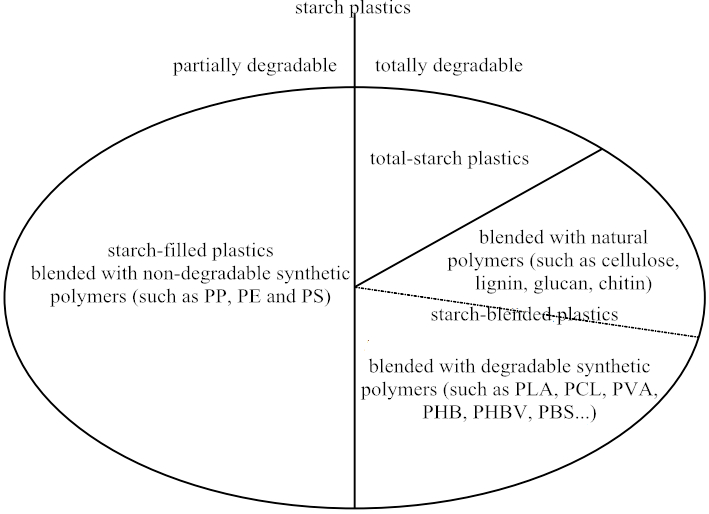

Development of starch plastics has gone through three steps: starch-filled plastics, starch-blended plastics and total-starch plastics. Starch content in each stage is higher than that in the previous stage.

Starch-filled plastics is mainly processed by blending starch with PE, PP, PS or other fossil-based plastics. Such starch plastics can only be degraded partially, which leads to its limited application. It’s more proper to burn it to reduce consumption of oil resources and emission of carbon dioxide.

Starch-blended plastics is the blend of starch and other biodegradable natural or synthetic polymers (such as cellulose, PBS and so on) and is totally degradable.

By destroying hydrogen bond by plasticizer or under other conditions and disordering starch molecule to decrease its glass transition temperature, we can get the total-starch plastics (or thermoplastic starch, TPS for short). Its starch content is higher than 90% and it’s totally degradable. For this reason, it, together with starch-blended plastics is both referred to as degradable starch plastics.

The direction and goal of starch plastic is to replace fossil-base plastics and alleviate problems of energy shortage and environment pollution. Degradable starch plastics is featured by good mechanical strength, strong flexibility, high impact strength, resistance to temperature/water/oil, no softening, strong deformability and so on.

“MaterBi”, the first starch plastics of Novarnont, an Italian enterprise, is composed of starch, cellulose, vegetable oil and so on. It is degradable and compostable and conforms to standard of EN 13432. The plastic can be processed to different products, including film (plastic bag, diaper surface, packing film, composting bag, agricultural film), injection molding products (plastic knife and fork, pen holder, hygienic products, disposable tableware), foamable products (buffering material), rubber products (car tire).

PSM biodegradable plastic is a product of Ecoplast, a Chinese company. It is made from starch and gains rigidity, toughness and elasticity by modifying and plasticizing starch. This product has been certified compostable (OK compost). The products made from it include disposable tableware, plastic bag, rubbish bag, hotel fittings, kitchen fittings, cosmetic bottle, coat hanger, etc.. Starch plastics is safe, non-toxic and biodegradable and can be widely used in pharmaceutical industry. The starch capsule made from starch plastics is also regarded as potential product to replace common gel capsule.

Dr. Li Hui and her colleagues prepare corn-starch capsule with corn starch as main material and PVA, sodium alginate and so on as excipients. Compared with gel capsules, corn-starch capsules have better film forming ability, water resistance, higher strength and shorter disintegration time.

Santander Ortega applies two different high-substitution propyl starch plastics to prepare nano particles. The research result shows that the particles have high coating efficiency to three drugs (flufenamic acid, testosterone and caffeine). For another thing, it’s also found that the particles can also improve the bioavailability of flufenamic acid and increases its effect while testing the potential application of particles as transdermal delivery carrier.

Currently, thermoplastic starch is of high cost, about 15% higher than traditional plastic products of PE, PP and PS. The high cost is one big bottleneck of its development. However, studies also show that the unit cost for thermoplastic starch production will even decrease to be lower than traditional plastics if the production scale expands.

English

English