GD-150A Automatic Tube Filling and Sealing Machine

1. Source and main specifications

GD-150A tube filling and sealing machine is a new filling equipment which is independently developed, designed and manufactured by our company, based on leading filling and sealing machine models and combined with practical tube production conditions. The machine is wholly closed in stainless steel and is suitable to fill and seal aluminium tubes of variable specifications. Its max. speed can reach 150 tubes per minute and actual normal speed reaches 120 to 150 tubes per minute. Its filling error is equal to more or less than 1%. The sealing type for aluminum tubes is hot air pressing,for plastic tube is hearting sealing pressing.

2. Introduction

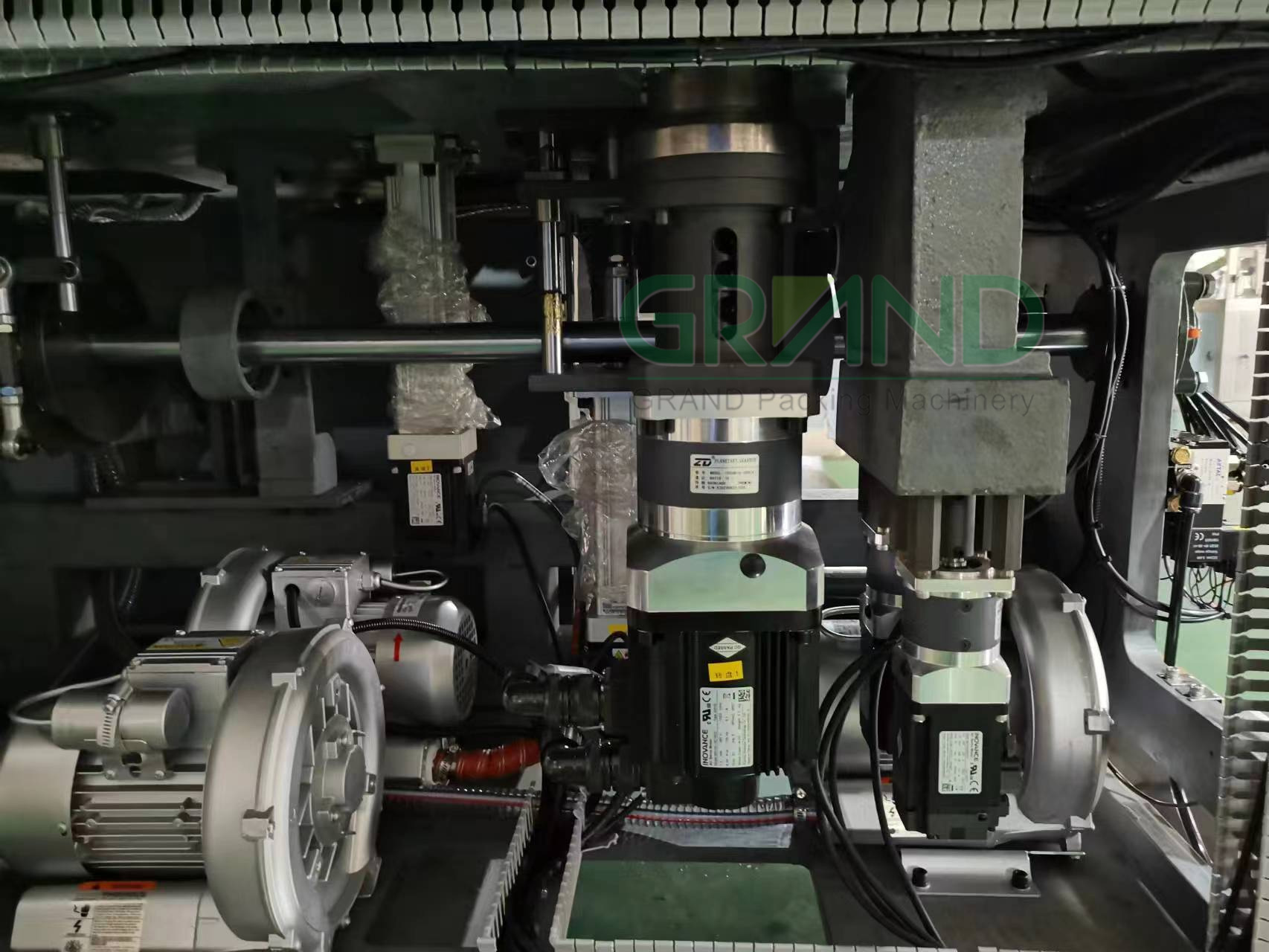

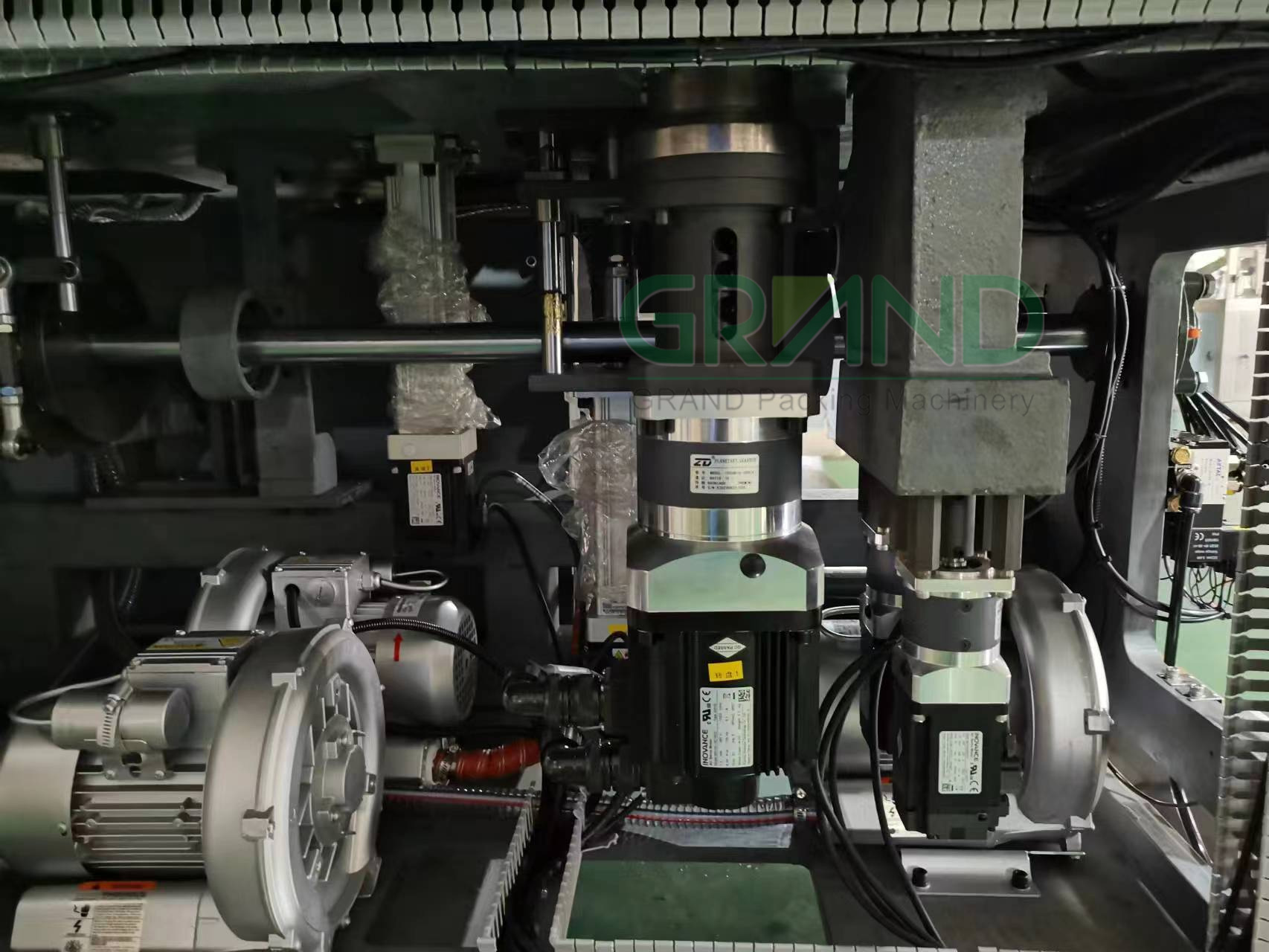

GD-150A is a full automatic double-station tube filling and sealing machine. Adopting advanced turntable double-servo drive technology and combining actual production conditions, the main drive system is unique. The cam is a forged from steel, which assures durability; adopting the advanced synchronous belt to convey tube holder. The whole machine adopts motion control mode communication programming and touch screen operation. With new technologies such as cam and pneumatic components to control mechanical action, ensuring safe, stable and reliable operation of the machine at high speeds, and making filling more accurate.

In order to meet GMP requirements, it adopts the wearable sliding bearing above the working table, which is lubrication-free, thereby reducing pollution. In order to guarantee high-speed operation, a synchronous belt is used. The whole machine is advances both in configuration and allocation. It is equipped with failure indication and alarm signaling system. The machine owning such characteristics eases operation, maintenance and cleanups. Moreover, it can be used alone, or linked with fully automatic cartoning machine, fully automatic overwrapping machine to form a production line.

3. Features

1) Host machine composition: aluminum tube feeding system, tube eye mark tracking mechanism, filling mechanism, automatic loading capacity adjusting device, lifting mechanism at filling, no tube no filling system, optional two-layer heat preservation hopper, sealing mechanism, tube discharging device, main transmission system, electric control system, and a set of mold (the underlined is the optional, and the mold specification depends on the buyers).

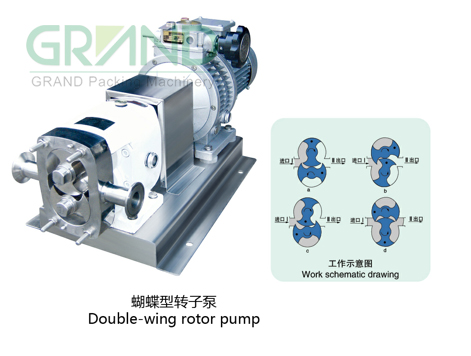

2) Filling and sealing procedure: aluminum tubes feeding into the holding cup by the turret --> stainless steel piston pump filling --> tube rolling, folding, embossing and sealing --> tube discharging.

3) Aluminum tube feeding system: manually feeding into the tube bin. The tube bin has a large capacity. For example, it can be loaded with more than 1500 tubes whose capacity is 20g. Driven by the servo, tubes are fed smoothly. The negative-pressure system enables the tubes to rightly drop into the tube holders. Shank switch can control whether aluminum tubes drops when the machine runs.

4) Filling mechanism: plunger valve structure.

5) Filling head: combination of blow-off and cut-off (to prevent leakage and wire drawing).

6) Filling range: aluminum tube, 3-250g.

7) Filling error: ±1% (as 20g filling volume as an example).

8) No tube no filling: two sets of separate no-tube-no-filling devices to provide double assurance.

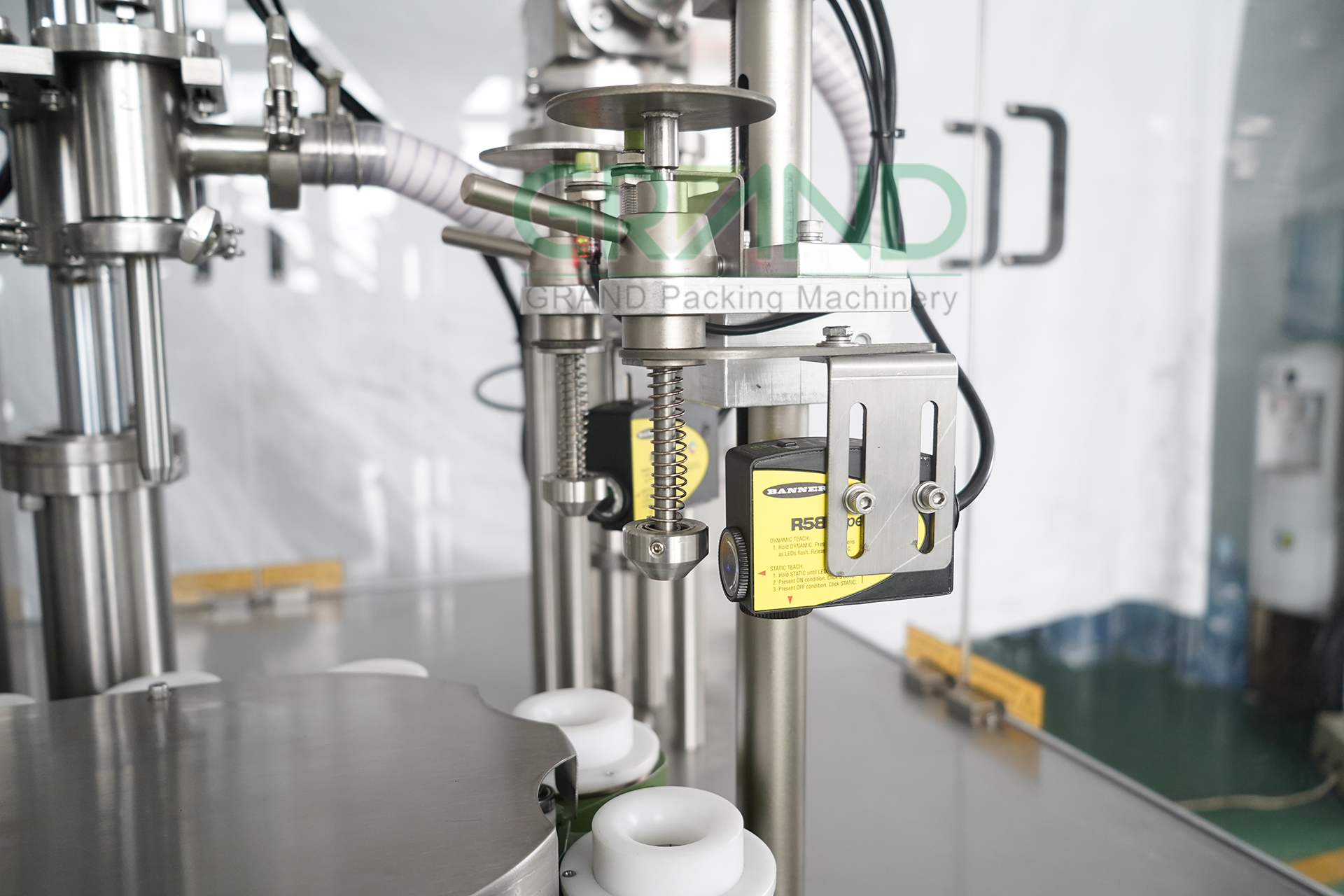

9) In order to solve the problem of air bubble and splash at filling, the filling heads can be declined to reach the proper position at bottom of aluminum tubes. The filling heads lift slowly and tubes are filled until filling finishes. Then they pause for a while. In this case, the filling nozzles are blown-off and cut-off to become clean. Finally the tubes rise and are conveyed to the next process. The filling head and nozzles are combined with a quick changeover joint to guarantee no ointment residue and easy disassembling and cleaning.

10) Sealing mechanism: cam connecting rod.

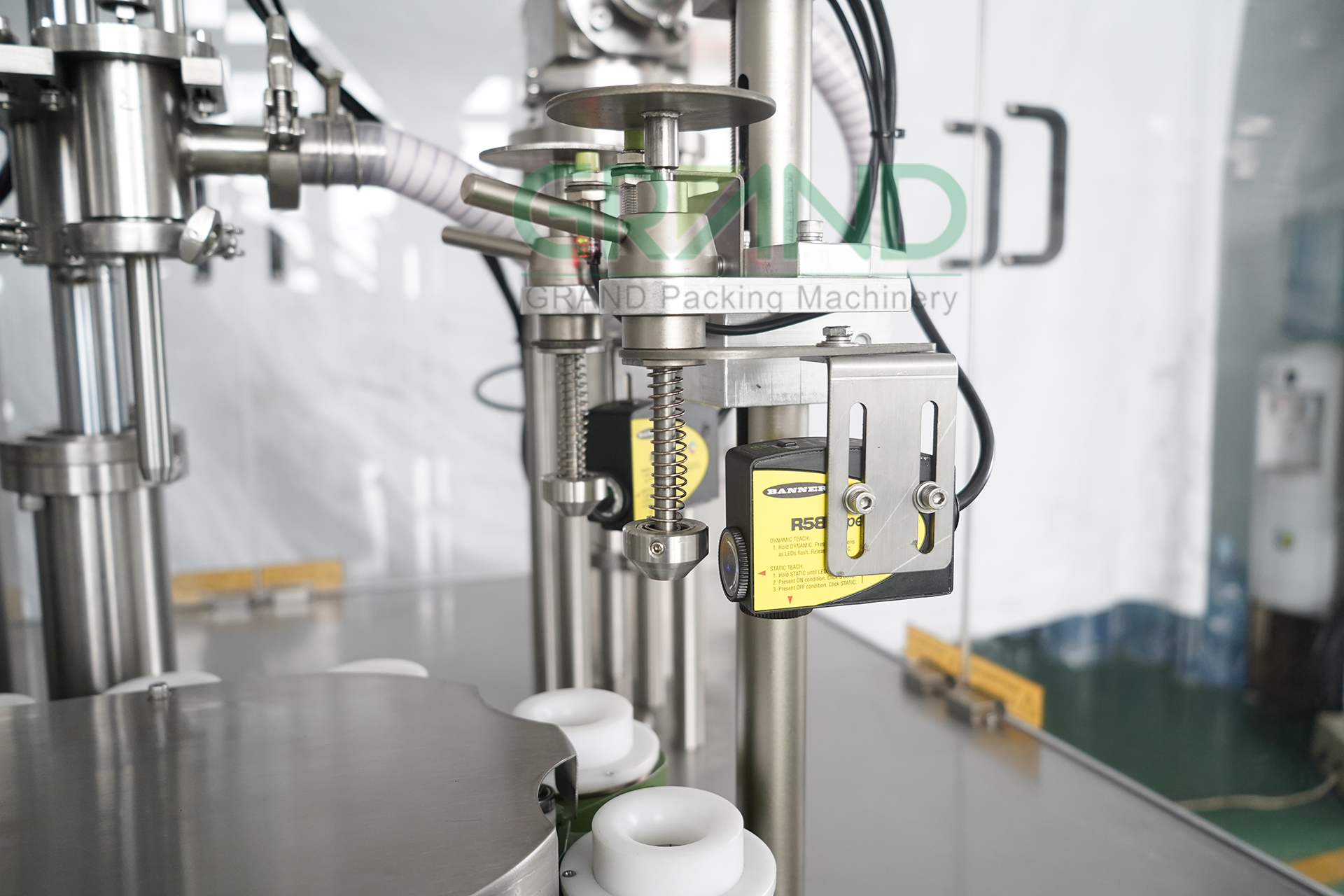

11) Main pneumatic components: adopts full set of SIEMENS electric system to ensure the stability of the whole system; and adopts AIRTAC pneumatic products and BANNER sensors.

12) Protective device:

l Main motor overload protection.

l Manual operation and automatic operation switch protection device.

l Lower-pressure protection switch.

l Emergency switch: manually pushed to make the machine stop in emergent case.

Servo motor: totally adopts 7 servo motors in mark alignment, filling, main motor, filling head lifting, turntable mechanisms, which are equipped with movement controller.

Main servo motor

LEISTER double-heating system (with tempering system)

Filling heads rising and falling, the in-tube height can be adjusted freely.

BANNER eye marks:

Hopper with heating and mixing (optional)

Heating water tank

Liquid level controller (optional)

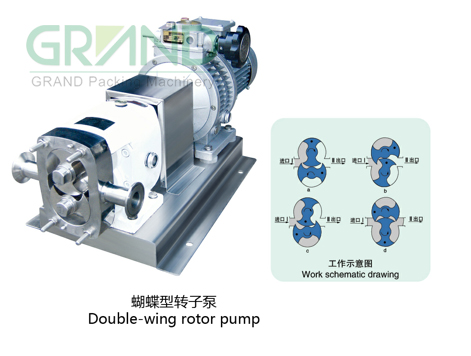

Feeding pump (rotor pump)

4. Technical specifications

Configuration Standard | Technical Specification | Remark |

Infrastructure |

Machine landing area | About 4m2 |

|

Working area | About 20m2 |

|

Chiller landing area | About 1m2 |

|

Coverage area | About 4m2 |

|

Machine dimension (L*W*H) | 2350 (excluding 200mm of discharge port) *1300*2200mm |

|

Integrated Structure | Union mode |

|

Weight | 2400Kg |

|

Machine case |

Machine case material | SUS304 |

|

Opening type of safety guard | Handle door |

|

Safety guard material | Plexiglass |

|

Frame below working table | Stainless steel |

|

Machine case shape | Square-shape |

|

Power |

Power supply | 50Hz/380V, 3P |

|

Main motor | 1.0KW |

|

Air heater | 3.0KW |

|

Jacketed hopper heating power | 2.0KW*2 | Optional |

Jacketed barrel stirring power | 0.18KW*2 | Optional |

Production capacity |

Operation speed | 120-150 tubes/min |

|

Filling range | 3-250g |

|

Suitable tube length | 50-210mm |

|

Suitable tube diameter | 13-50mm |

|

Pressing device |

Pressing guiding main component | CHINA |

|

Pneumatic control system |

Low voltage protection | AIRTAC |

|

Pneumatic component | AIRTAC |

|

Working pressure | 0.5-0.6MPa |

|

Compressed air consumption | 1.5m³/min |

|

Electrical control system |

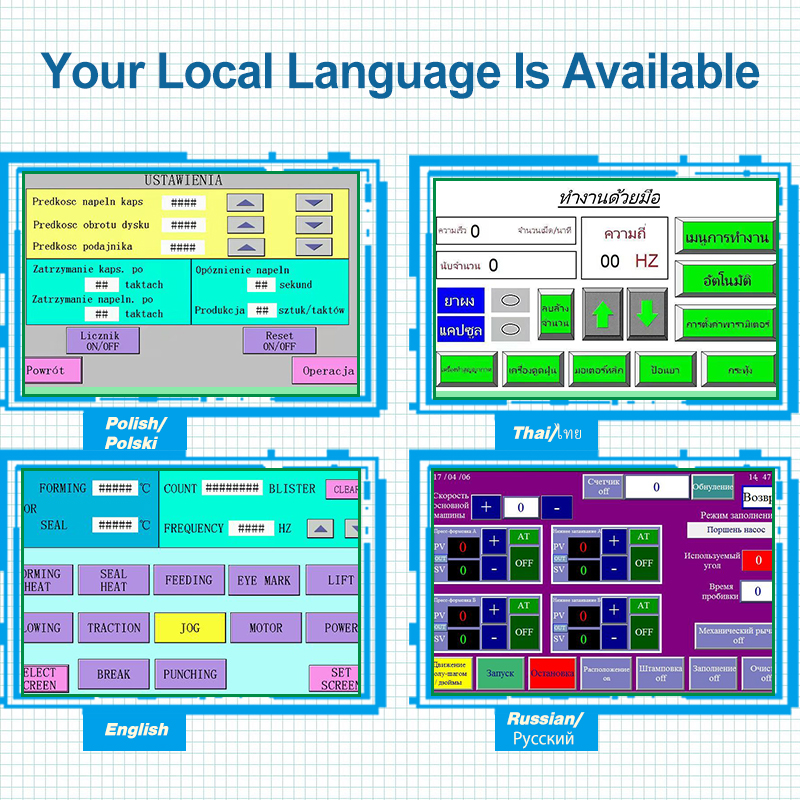

Control mode | PLC+Touch Screen |

|

PLC | SIEMENS |

|

Frequency inverter | SIEMENS |

|

Touch screen | SIEMENS |

|

Encoder | OMRON |

|

Filling monitor | AUTONICS | Optional |

Master power switch | MOELLER |

|

Eye mark sensor | BANNER |

|

Suitable tube & other devices |

Suitable tube | Aluminum tube |

|

Obliquely hanging lining-up tube bin | Speed adjustable |

|

Material contacting with products | SUS316L |

|

Jacketed hopper heat preserving device | Temp. setting according to material and filling demand | Optional |

Jacket hopper stirring device | In case of no material mixing, it remains fixed in hopper | Optional |

Auto embossing device | Embossed on single side or double sides at the end of sealed tube. |

|

Note: Due to the continuous improvement of the machine, electrical parts would be changed without notice.

5. The advantage of our machine: unique independent double-filling system

5.1. Disadvantage of the common single filling system in the market

The structure is complicated, so it is difficult to replace parts. If in failure, the whole machine need to be shut down for maintenance.

1) With the complex structure, various parts and perforated screw in the market single filling system, it is difficult to replace and clean the filling heads, materials hopper and pistons, the disassembly and assembly process is complicated and time-consuming.

2) The cylinder is installed in a concealed position. If the cylinder is damaged, the surrounding parts need to be taken apart to replace a cylinder, which is time-consuming.

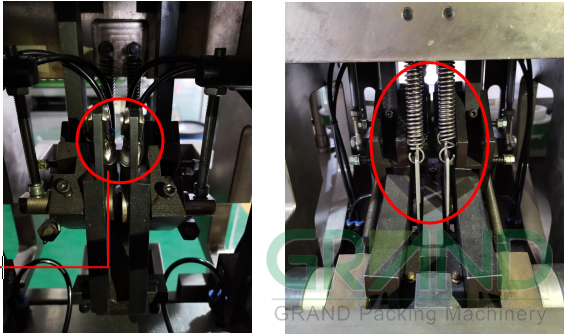

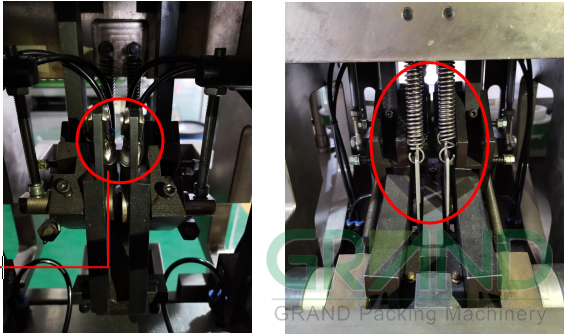

3) The spring need to be replaced after a long operation. While the upper hook of the spring is not visible, so it is difficult and time-consuming to replace.

5.2. Advantage of the unique double-filling system

The structure is simple and easy to replace. Moreover, the independent double-filling system can fill different volumes in different tubes of different diameters, even with different materials for filling, especially for parent-child package or A-B package. If one filling system is in failure, the other can operate normally, avoid the whole machine shut down, just in less production.

When cleaning or replacing the filling heads and material barrel, only need to open the 4 quick-release clamps, which is very convenient and fast without installation difficulty and technical requirements.

Double-filling system: The drum-type tube feeding avoids tubes stuck which caused by the old stainless steel bead being pressed.

Double filling heads Double eye mark tracking

Special design: the lifting pressing block ensures the tube holders will not be ejected in oblique position for normal tube discharge.

The touch screen with swing arm is convenient for real-time and easy operation.

Company Information

ABOUT US

Hunan Grand Packing Machinery Co.,Ltd is specialized in the pharmaceutical and packing machinery for more than 10 years, such as plastic ampoule forming filling and sealing machine, capsule filling machine, blister packing machine, strip packaging machine, cartoning machine etc. We have provided services and machines to many different countries and regions in the whole world, such as Indonesia, Thailand, Malaysia, Philippines, New Zealand, Korea,the Middle East area, Poland, Belgium, France, UK, Greece, Italy, Turkey, USA, central and south America such as Trinidad and Tobago,Mexico, Brazil, Russia, Ukraine, UZ, Tunisia, Algeria, Morroco etc. And we always gain the good reputation from customer both from the machine quality and after sales service.

Our Service

1.We will dispatch engineers to your site for machine installation and commissioning, and also do the training for your technicians.

2.We makes guarantee of the machine for 12 (twelve) months. During this Warranty period, the seller will provide free spare parts that cause by the machine’s quality within 10 days by fast courier upon receipt of buyer’s notice.(we will also provide one set of spare parts /wear &tear parts to customer along with the shipment of the machine.

3.We warmly welcome the suggestions from customer to make us grow better and produce better machine along with providing better service to customer, and create more value for customer.

4.Before placing the order or before shipping, welcome to our factory to take a visit to inspect our machine. we will pick you up in the airport or train station and arrange your following schedule in our city to bring you a nice journey during this visit.

English

English