*The connection between the mold and the transducer of this equipment adopts titanium alloy screw

The screw link made of titanium alloy is not easy to break and durable, reducing the failure rate when the machine is sealed.

*This equipment adopts C440 stainless steel cutter

C440 stainless steel material cutter, high hardness and durable cutter.

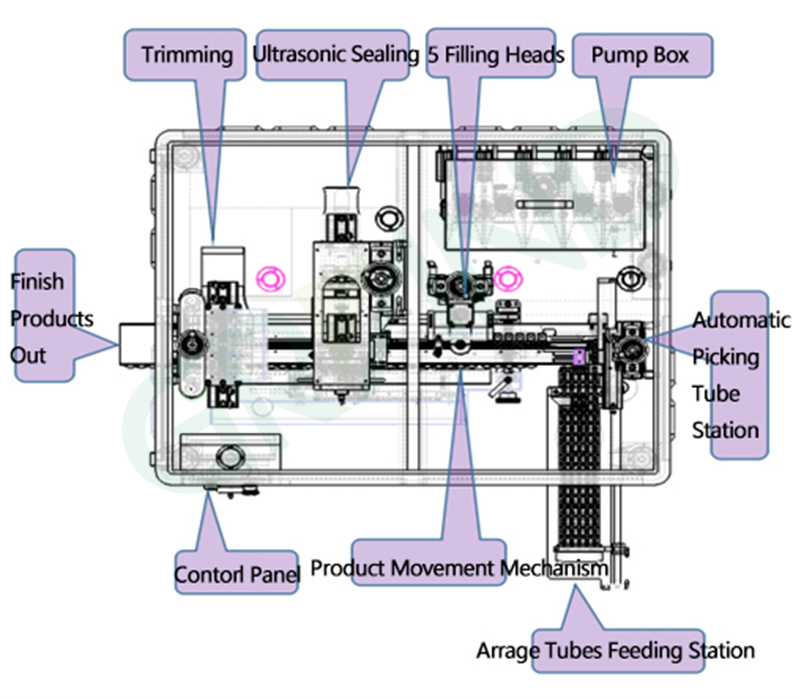

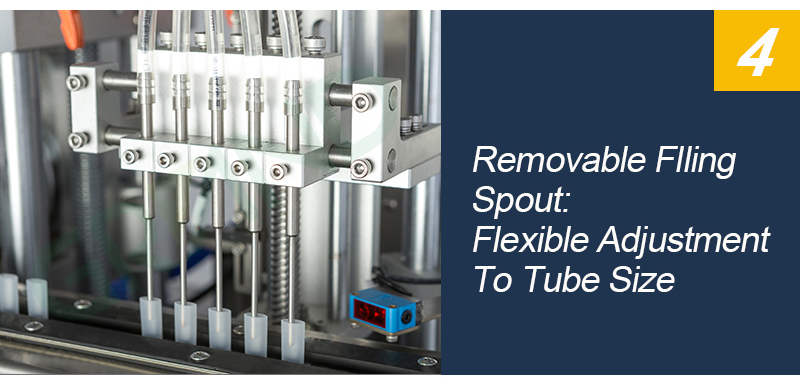

1. This machine automatically completes a series of actions such as pipe dropping, filling, tail sealing, tail cutting, and finished product delivery. It is fully automatic, saving labor and reducing production costs; 2. Equipped with safety devices and overload protection;

3. Servo motor precise positioning;

4. Ultrasonic technology is used for sealing, and the sealing effect is stable and long-lasting; the sealing line is clear and does not deform;

5. Independent research and development of digital ultrasonic automatic frequency tracking electric box, no need to manually adjust the frequency, increase the automatic power compensation function, and will not cause the power of the machine to drop due to long use time. The power can be adjusted freely according to the material and size of the hose, the output is stable, the failure rate is extremely low, and the service life is longer than that of ordinary electric boxes;

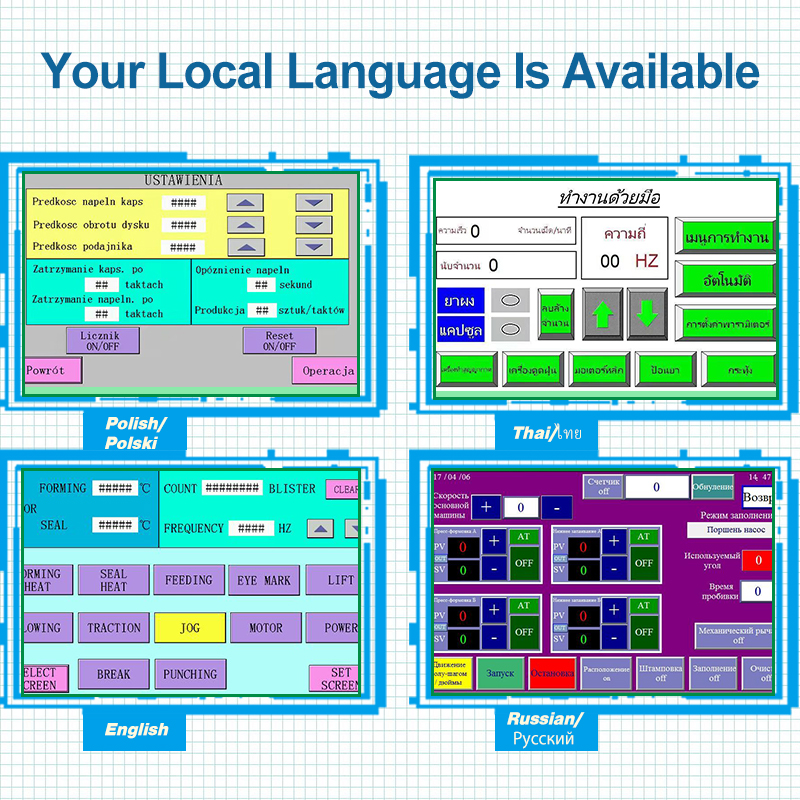

6. It adopts PLC touch screen control,equipped with a fault alarm system, and the fault information is displayed on the touch screen, which is clear at a glance, and can quickly locate and solve problems;

7. The whole machine is made of 304 stainless steel, acid and alkali resistance, corrosion resistance;

8. The machine is equipped with an automatic identification system, no tube, no filling and no sealing, reducing the loss rate of the machine and mold;

9. Five-head precision ceramic pump filling machine, filling accuracy ± 0.02ml;

10. The design of the sealing mold adopts an embedded structure, which is convenient for disassembly and debugging;

11. The processed parts are all processed by grinding and chamfering.

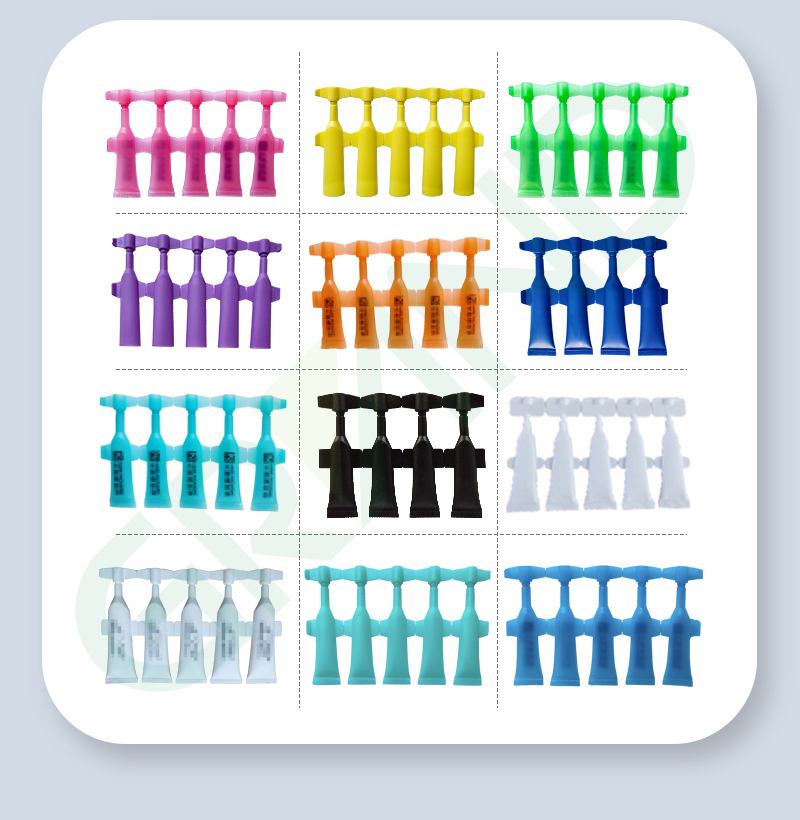

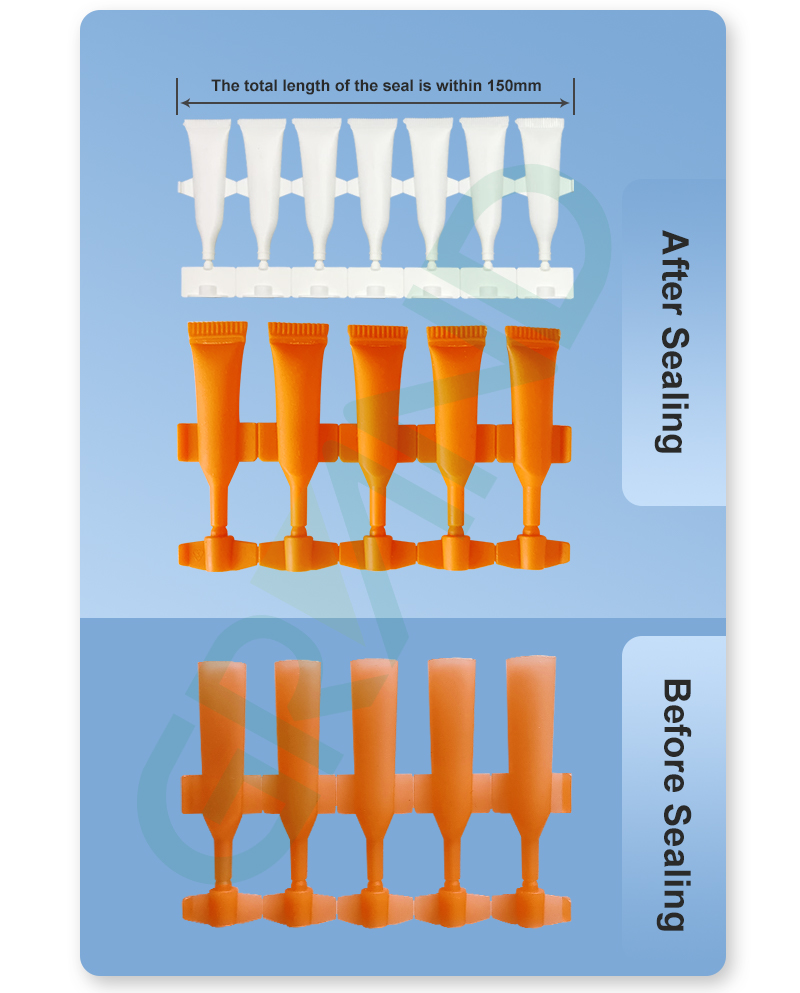

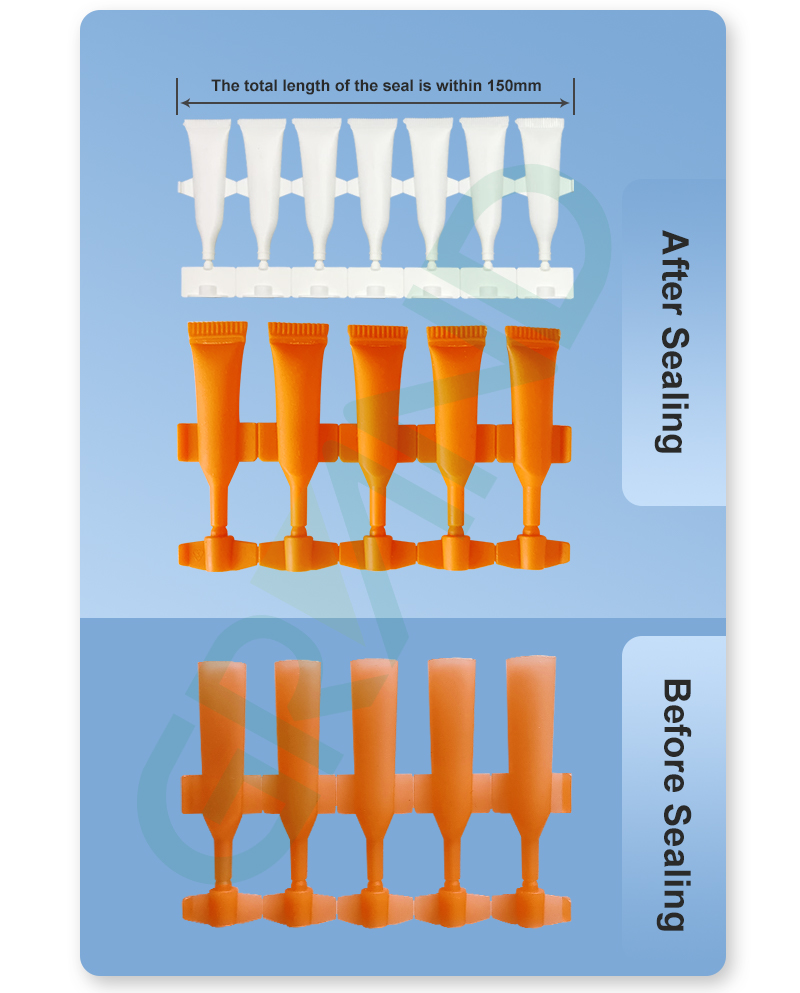

The strip mono dose tube for single use is made at 1ml, 2ml, 3ml,5ml and 10ml.

The tube type that can be applied on the machine are:Plastic Tube,Aluminum Plastic Tube,Composite tube

It is used for packing essential oil, serum, gel, eye cream, sample product, pet supplies etc.

Machine features:

1. Five stations are integrated on one machine so that the machine can fill tubes in mass production;

2. Tubes are fed automatically and the following filling, sealing, end cutting and discharging are finished automatically;

3. The machine adopts ultrasonic sealing technology for shorter heating time, stabler and neater sealing, no distortion and low failing rate (<1%).

4. Automatic ultrasonic controller allows no manual adjustment of ultrasonic frequency and consistent ultrasonic performance after long time use. It can also adjust the ultrasonic strength according to the tube material and size. It works stably in high precision and long service life.

5. PLC and touch screen can directly show the alarming information, locate the error and display its resolution immediately.

6. Each station can be controlled independently on the touch screen for easy machine adjustment. The user or the operator can debug the machine with only one tube to save time and material.

7. The standard machine is equipped with a peristaltic pump filling system for high-accuracy liquid filling.

8. The cam indexing system can work precisely for the six stations.

9. The machine is made of SS304 to be resistant for acid and alkali.

10. No tube, no filling and no sealing to reduce tube material waste and save energy.

Main technical

| Model | HX-005H | HX-005 | HX-003 |

| Auto/Semi-auto | Fully Auto | Semi Auto |

| Funtion | Filling and Sealing | Sealing |

| Safety Protection | Safety device equiped | Overload protection |

| Overload protection |

| Station | Servo Motor Driven Chain Type | 6 Stations (Rotary Table) | 1 Stations |

| Tube type | Strip monodose vials tubes |

| Tube material | PP/PE plastic composite pipe/Aluminum plastic tube,etc |

|

| Automatic Identification | No tube-no filling&no sealing | No tube no sealing |

| Fault Alram | Failure warning feature | / |

| Frequency | 20 kHz |

| Power | 2.6 KW | 2.2 KW | 2 KW |

| Power supply | AC220V/110V |

| Filling system | 5 heads Valveless Ceramic Plunger Pump (liquid) | / |

| 5 heads Rotary Valve Ceramic Plunger Pump (paste) | / |

| Filling Range | 0.3-10ml Valveless Ceramic Plunger Pump | / |

| 1-10ml Rotary Valve Ceramic Plunger Pump | / |

| Filling Error | ±0.02g | ±0.05g | / |

| Capacity | 15-20strips/min | 10-13strips/min | 8-12strips/min |

| Tube diameter | 1-7 strip/length 50-140mm |

| Tube height | 50-150mm |

| Working pressure | 0.6MPa |

| Air comsumption | 0.4m3/min |

| Dimension (mm) | 1300*1300*1950 | 1300*1000*1550 | 560*540*880 |

| N.W/G.W (Kg) | 420 | 330 | 105 |

Production details

Sample Display

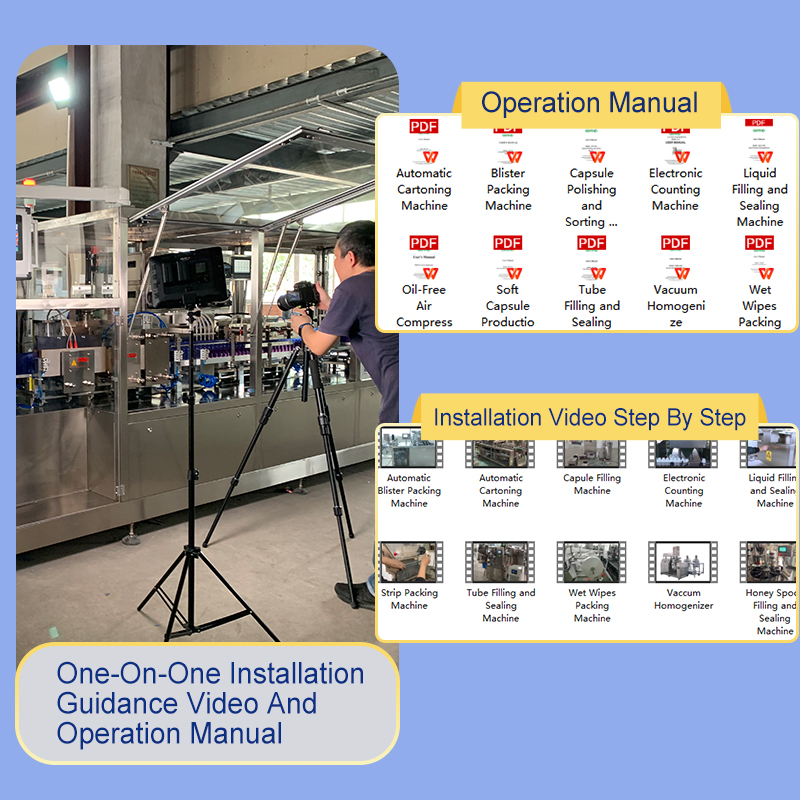

Our Services

Service 3: We will dispatch engineers to your site for machine installation and commissioning, and also do the training for your technicians.

Service 4: We makes guarantee of the machine for 12 (twelve) months. During this Warranty period, the seller will provide free spare parts that cause by the machine’s quality within 10 days by fast courier upon receipt of buyer’s notice.(we will also provide one set of spare parts /wear &tear parts to customer along with the shipment of the machine.

Service 5: We warmly welcome the suggestions from customer to make us grow better and produce better machine along with providing better service to customer, and create more value for customer.

Service 6: Before placing the order or before shipping, welcome to our factory to take a visit to inspect our machine. we will pick you up in the airport or train station and arrange your following schedule in our city to bring you a nice journey during this visit.

Company Information

ABOUT US

Hunan Grand Packing Machinery Co.,Ltd is specialized in the pharmaceutical and packing machiney for more than 10 years, such as plastic ampoule forming filling and sealing machine, capsule filling machine, blister packing machine, strip packaging machine, cartoning machine etc. We have provided services and machines to many different countries and regions in the whole world, such as Indonesia, Thailand, Malaysia, Philippines, New Zealand, Korea,the Middle East area, Poland, Belgium, France, UK, Greece, Italy, Turkey, USA, central and south America such as Trinidad and Tobago,Mexico, Brazil, Russia, Ukraine, UZ, Tunisia, Algeria, Morroco etc. And we always gain the good reputation from customer both from the machine quality and after sales service.

customer visit at our factory and our visit to customer

Our factory

We are cooperating with various kinds of factories and companies in different fields, including pharmaceutical factory, food factory, supplement factory, agrochemical factory such as for pesticide, fertilizer, personal care product factory, such as for cosmetic product, daily use product, stationery factory, hardware factory etc.

English

English