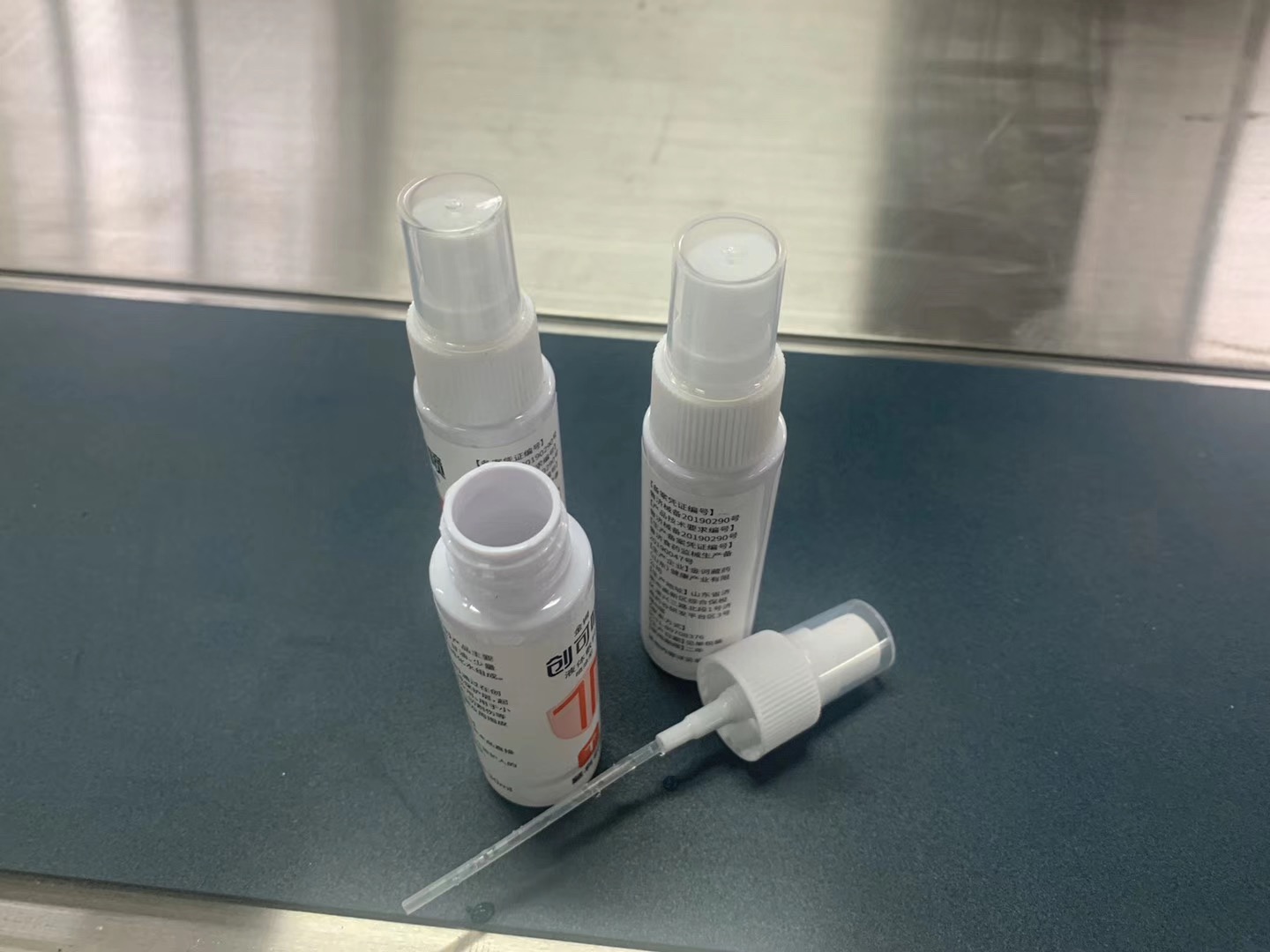

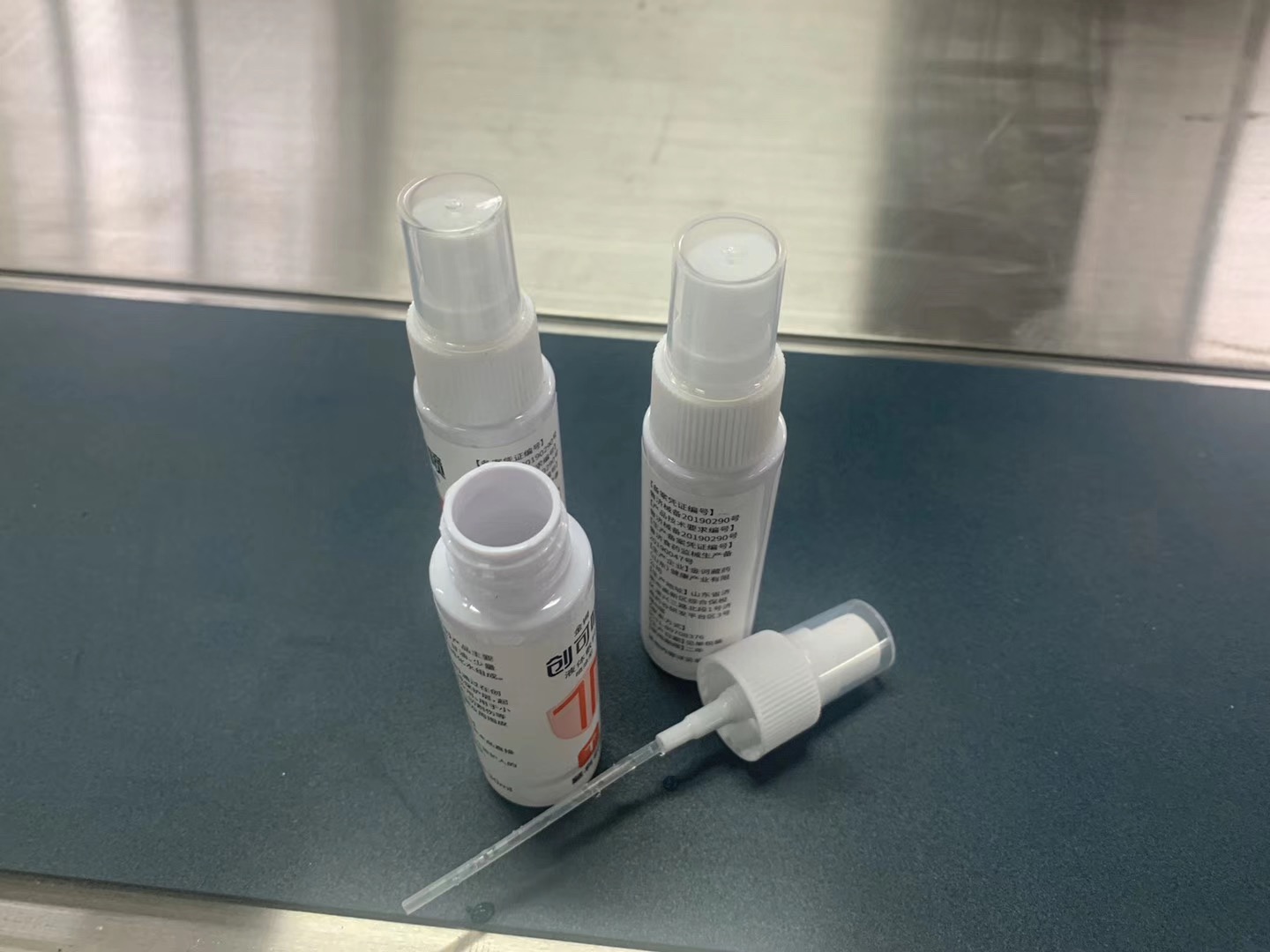

(1)Spraying bottle filling & capping machine ZHS-50

Brief introduction to the equipment

The automatic liquid filling and capping machine is the latest product developed by our company to meet market demand after introducing foreign advanced technology. The machine can be applied to fill round, square, or irregular glass and plastic bottles. The machine applies embolic metering pump or peristaltic pump. It is a machine of covering automatically, capping automatically and machine electric all in one. The machine is economic, covers a small area and can be widely applied in liquidity packing of many fields such as pharmacy, pesticide, chemical industry, food, cosmetic, etc.. PLC controls frequency conversion to achieve high automation. Packing volume can be adjusted conveniently. The filling volume of all metering pumps can be adjusted together, or that of every metering pump can be respectively adjusted slightly. Operation and adjustment is simple and convenient. Filling needle is designed with anti-dripping equipment. The needle sneaks into the bottom of bottles and rises slowly to avoid bubbles when filling. The machine is designed under the requirements of GMP.

Operation principle

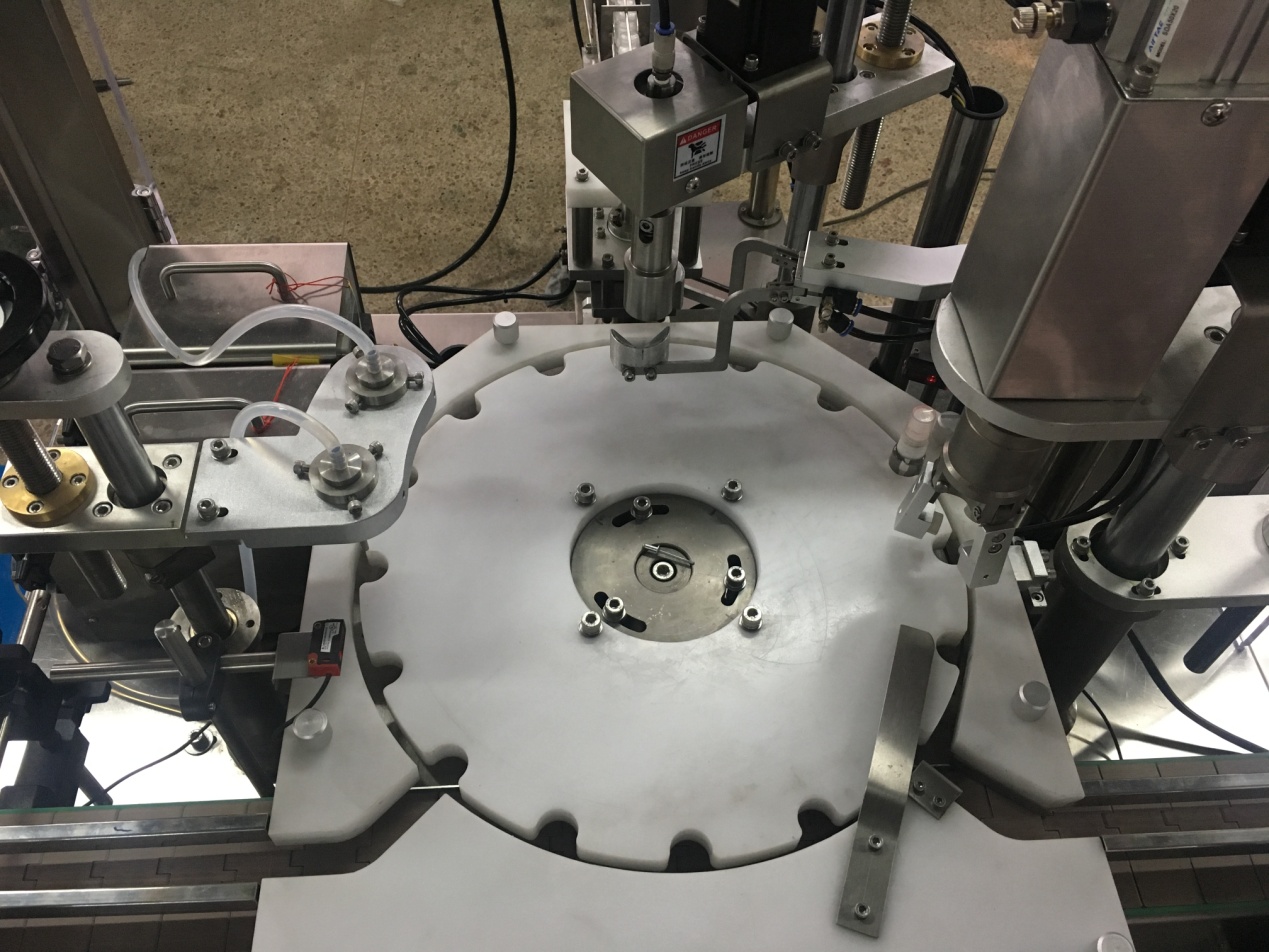

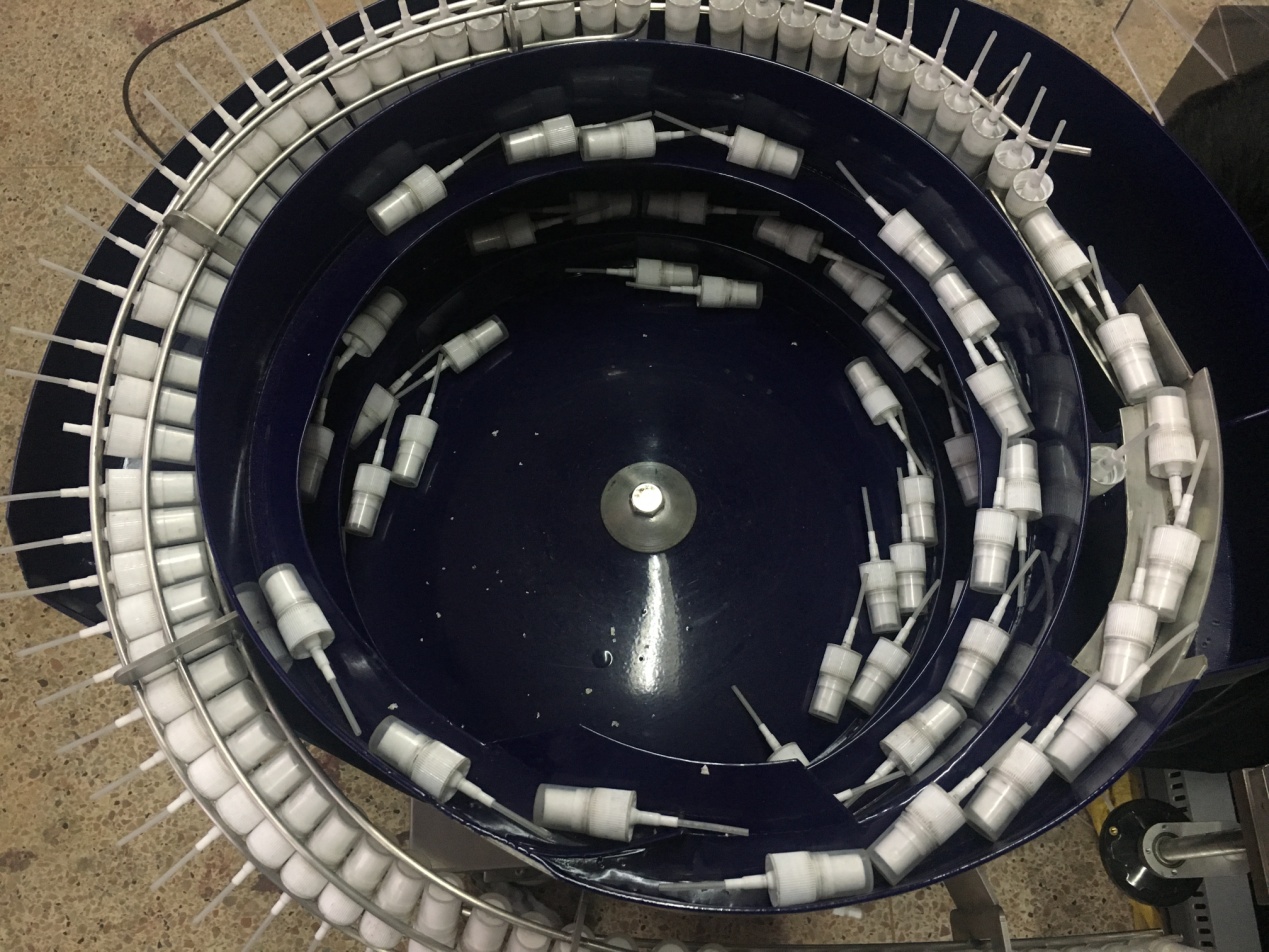

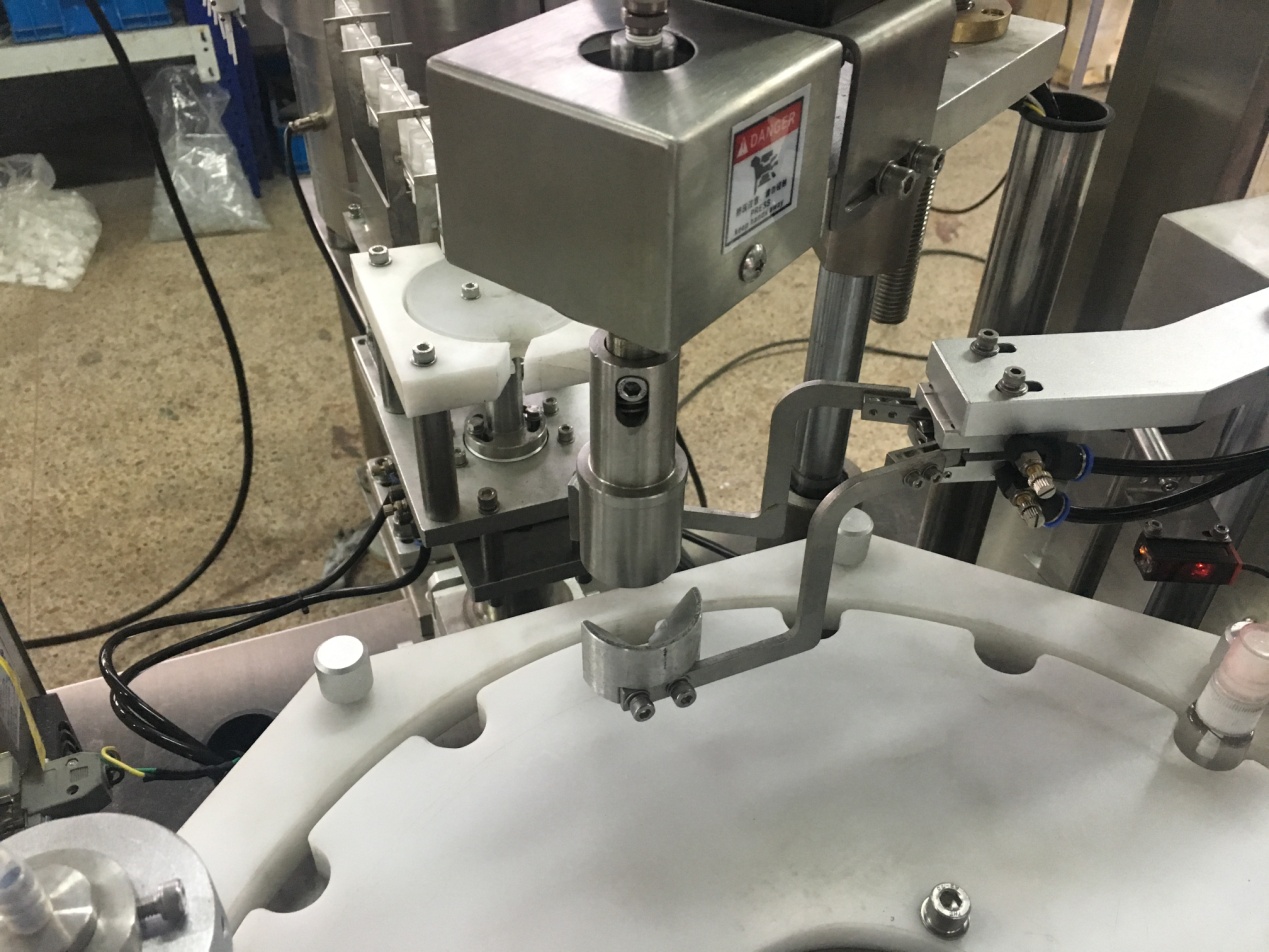

Several operations of the equipment are bottle unscrambling, filling automatically, arranging spraying cover automatically, covering with swinging arm, and capping by servo.

1. Bottle unscrambling: Putting the unfilled bottles on the conveyor manually.

2. Detecting: Photoelectric sensors detect if there is empty bottle on the main turntable and send the signal to PLC to control filling when there are bottles, or not filling when there is no bottles.

3. Filling: If it is detected that there are bottles, PLC will control the filler to sneak into the bottle and fill in particular volume.

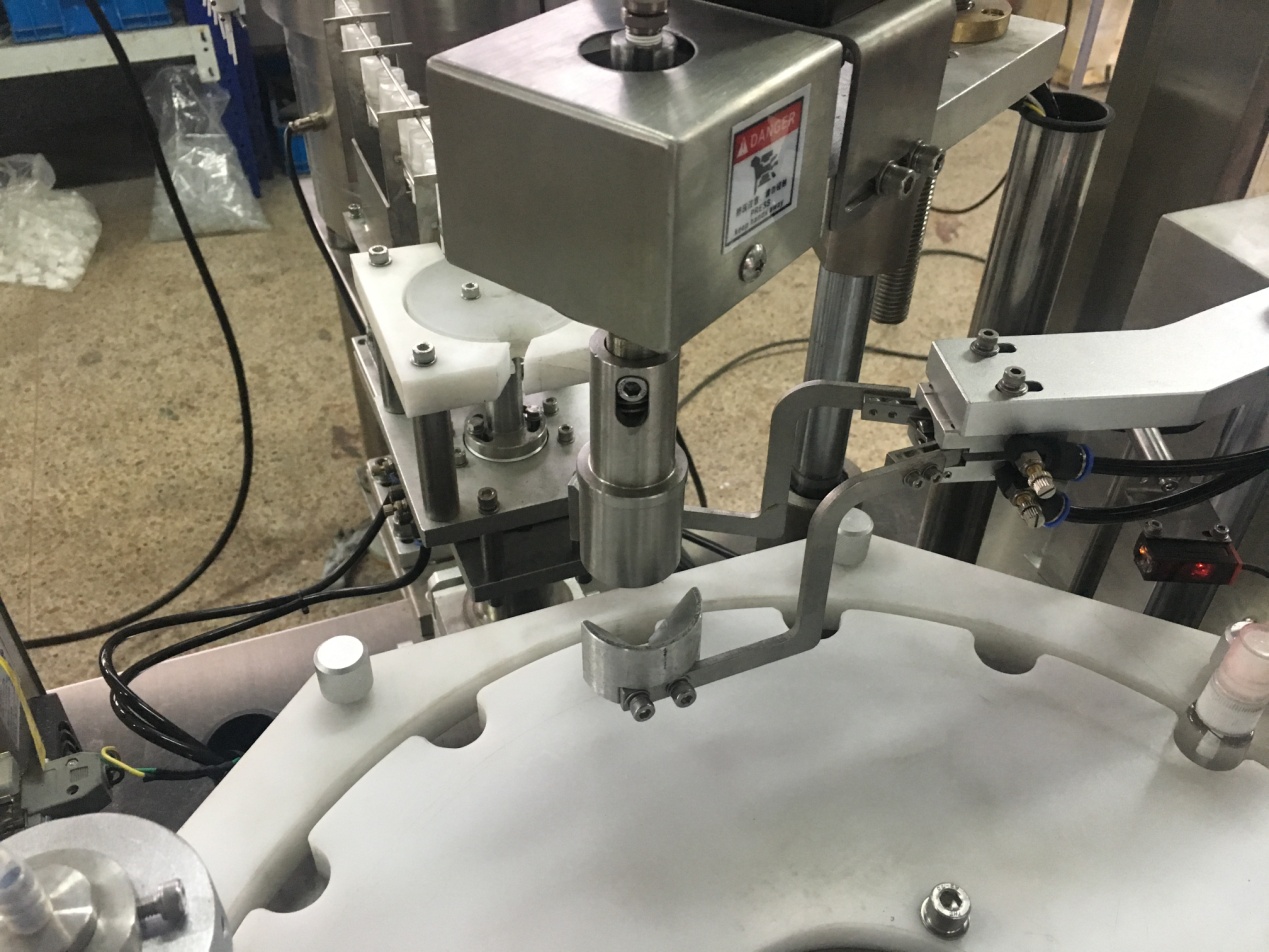

4. Spraying cover: If it is detected that there are bottles, the swinging arms will cover and pre-cap.

5. Capping: Torque and rotation speed are controlled by servo motor to ensure that covers are capped and the tightness is consistent.

6. Bottle leaving: The well capped bottles are conveyed out of the conveyor.

Parameters:

Filling volume | 5-50ml |

Production quantity | 30-40 bottles per minute |

Filling accuracy | ≥99% |

Covering rate | ≥99% |

Power supply | 220V 50HZ |

Power | 1.5KW |

Dimensions (L*W*H) | 2000*1500*1900 mm |

Machine parts in detail

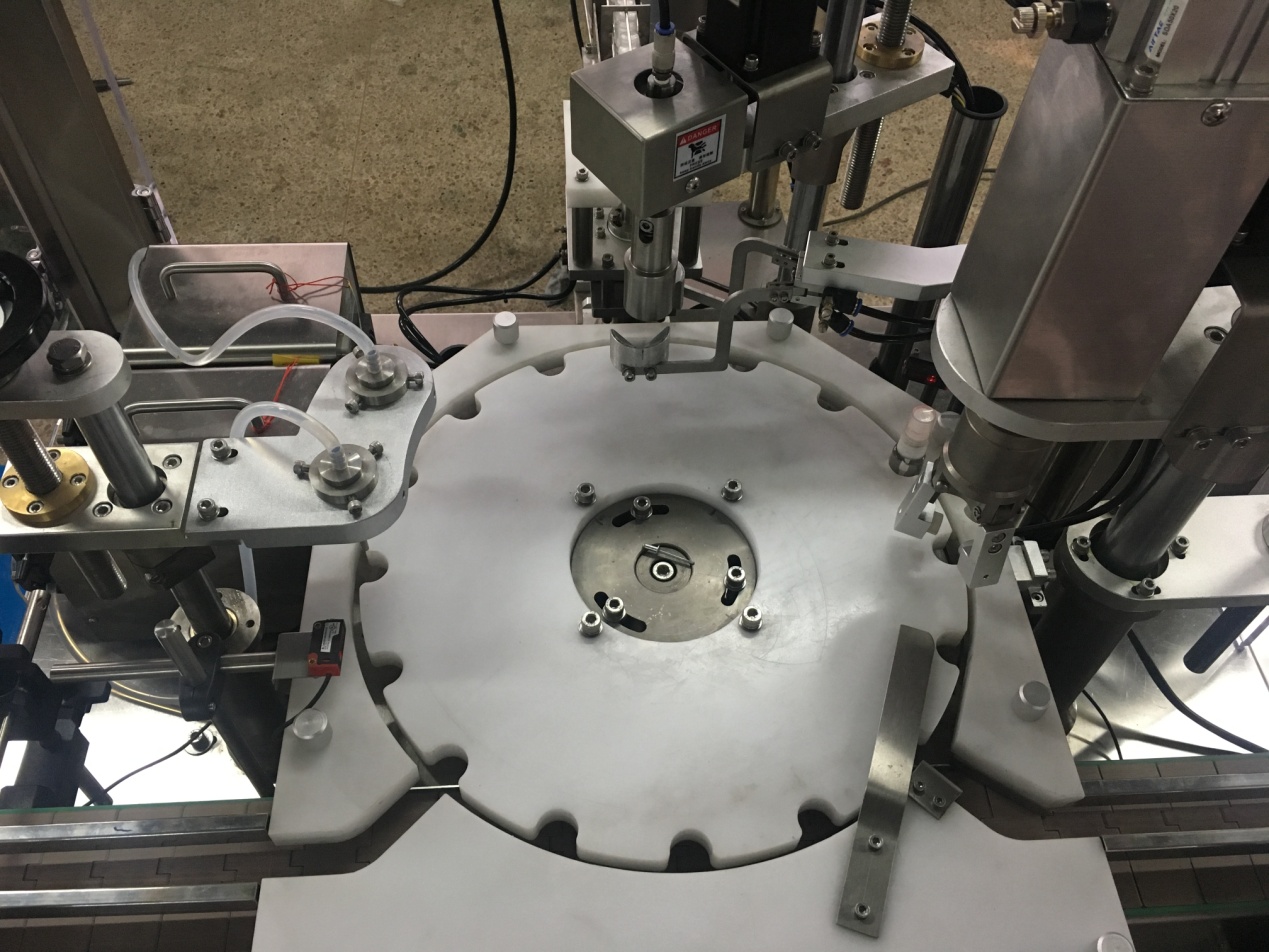

Bottle turning table

Peristaltic filling pump

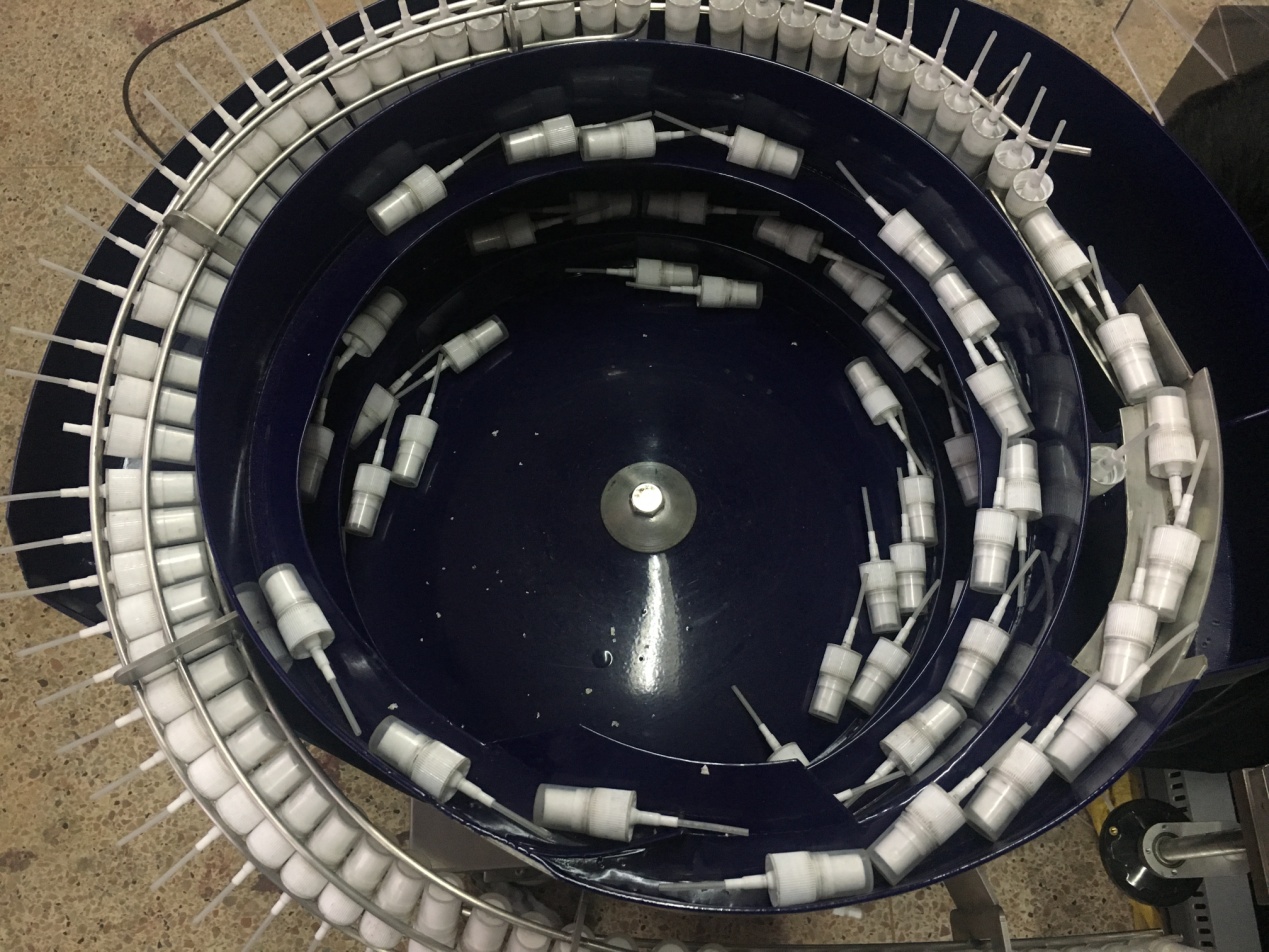

Automatic spraying head vibrating feeder

Automatic capping by screwing or pressing

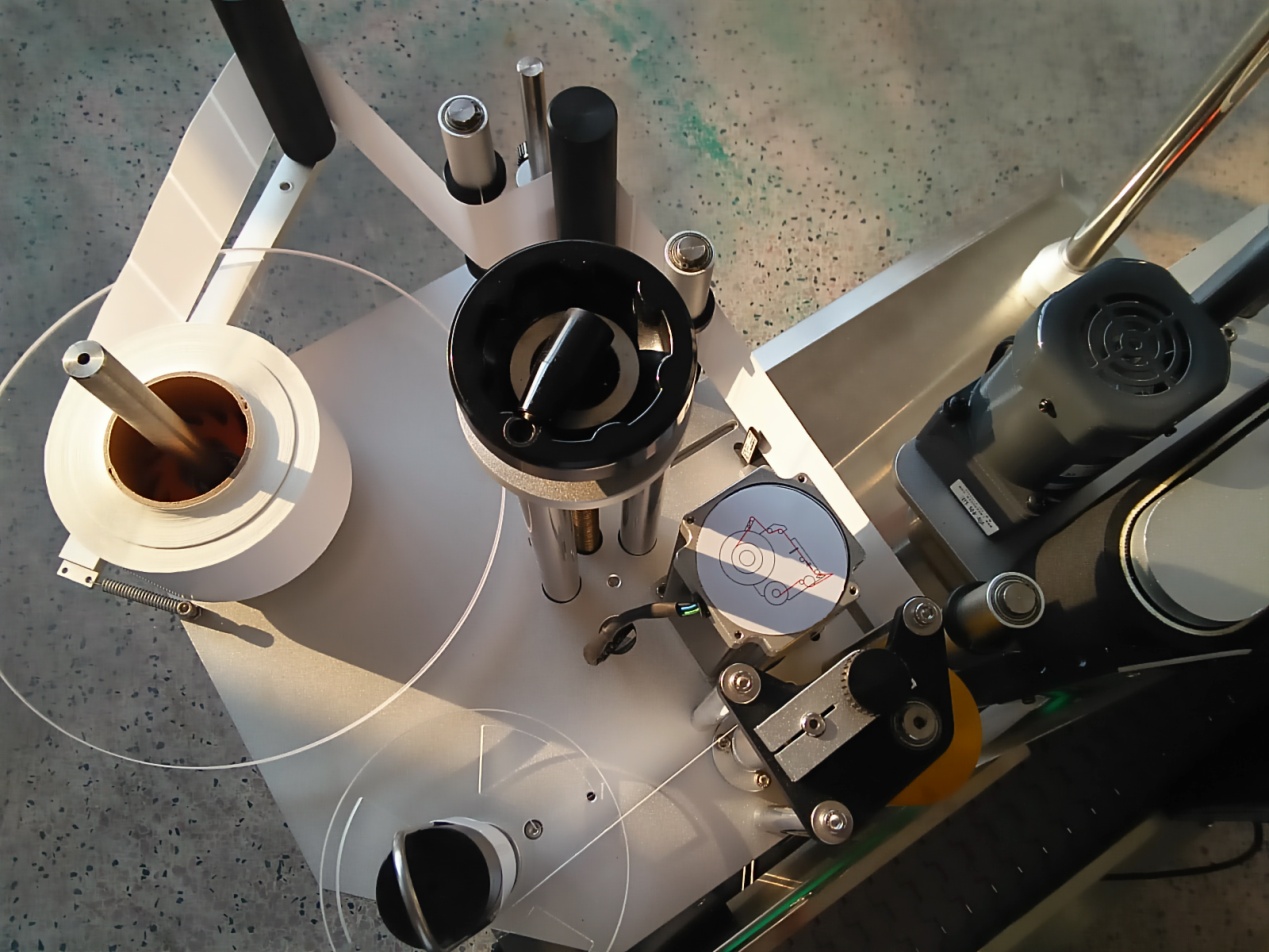

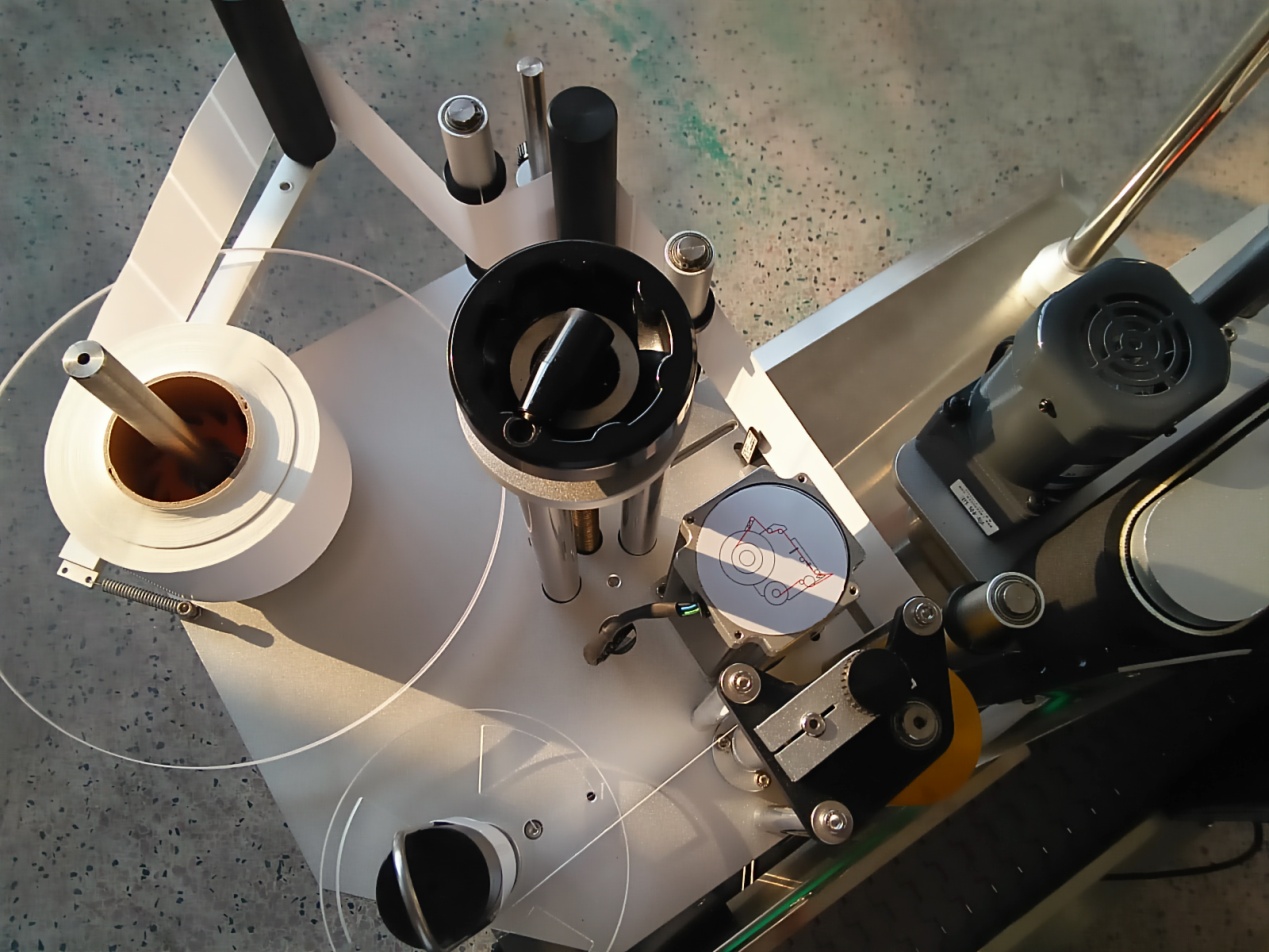

(2) Automatic sticker labeling machine ZHTB01

The machine can be applied to automatically label many products like food, medicine, cosmetics, electronic class, hardware, car parts, stationery, battery, round bottles of oil products, and all sorts of packing products.

Features:

1. Labeling on the external surface of round bottle products. Small half labels, half labels, large half labels, and full labels ( fully labeled along the circumference) can be labeled along the circumference.

2. Applying Human Machine Interaction for direct display and simple operation. Many groups of memory equipments are equipped. Therefore, no new settings will be needed if the product is renewed.

3. Acquiring functions of error displaying and warning. The machine stops and warns when labels ran out or labeling discontinue.

4. Finishing of and special treatment to the components guarantee good quality and high accuracy, steady performance, and long service life of labeling.

Parameters

Label length | 10-250mm |

Label height | 20-100mm |

Labeling diameter | 20-100mm |

Production quantity | 20-120 bottles per minute |

Label reel diameter | 76mm |

The maximum external diameter of label roll | 300mm |

Bottle specifications | Diameter | 20-100mm |

Height | 30-150mm |

Power | 0.55KW |

Power supply | 220V 50/60HZ |

Dimensions (L*W*H) | 2000*1000*1400 mm |

Net weight | 120Kg |

Our Services

Service 3: We will dispatch engineers to your site for machine installation and commissioning, and also do the training for your technicians.

Service 4: We makes guarantee of the machine for 12 (twelve) months. During this Warranty period, the seller will provide free spare parts that cause by the machine’s quality within 10 days by fast courier upon receipt of buyer’s notice.(we will also provide one set of spare parts /wear &tear parts to customer along with the shipment of the machine.

Service 5: We warmly welcome the suggestions from customer to make us grow better and produce better machine along with providing better service to customer, and create more value for customer.

Service 6: Before placing the order or before shipping, welcome to our factory to take a visit to inspect our machine. we will pick you up in the airport or train station and arrange your following schedule in our city to bring you a nice journey during this visit.

Company Information

ABOUT US

Hunan Grand Packing Machinery Co.,Ltd is specialized in the pharmaceutical and packing machinery for more than 10 years, such as plastic ampoule forming filling and sealing machine, capsule filling machine, blister packing machine, strip packaging machine, cartoning machine etc. We have provided services and machines to many different countries and regions in the whole world, such as Indonesia, Thailand, Malaysia, Philippines, New Zealand, Korea,the Middle East area, Poland, Belgium, France, UK, Greece, Italy, Turkey, USA, central and south America such as Trinidad and Tobago,Mexico, Brazil, Russia, Ukraine, UZ, Tunisia, Algeria, Morroco etc. And we always gain the good reputation from customer both from the machine quality and after sales service.

customer visit at our factory and our visit to customer

Our factory

We are cooperating with various kinds of factories and companies in different fields, including pharmaceutical factory, food factory, supplement factory, agrochemical factory such as for pesticide, fertilizer, personal care product factory, such as for cosmetic product, daily use product, stationery factory, hardware factory etc.

English

English