GDF-220Z High Speed Tube Filling And Sealing Machine

Speed ≤ 220 tubes/min

Double-head high-speed aluminum tube filling

1. According to the requirements of packing materials and filling speed, RGF-220Z double-head high-speed aluminum tube filling and sealing machine is recommended. The machine is suitable for filling and sealing aluminum tubes in designed speed of 220 tubes/min.

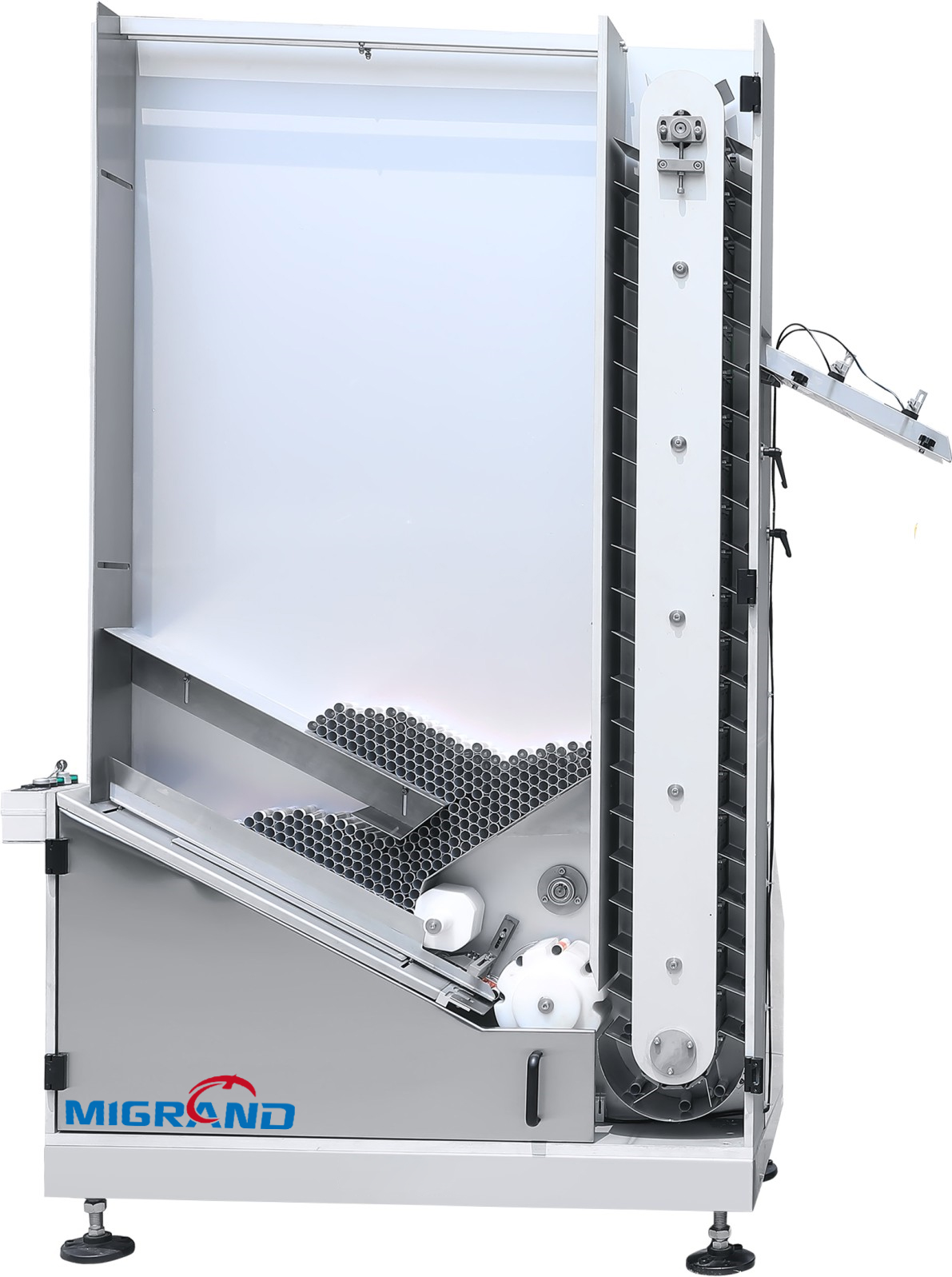

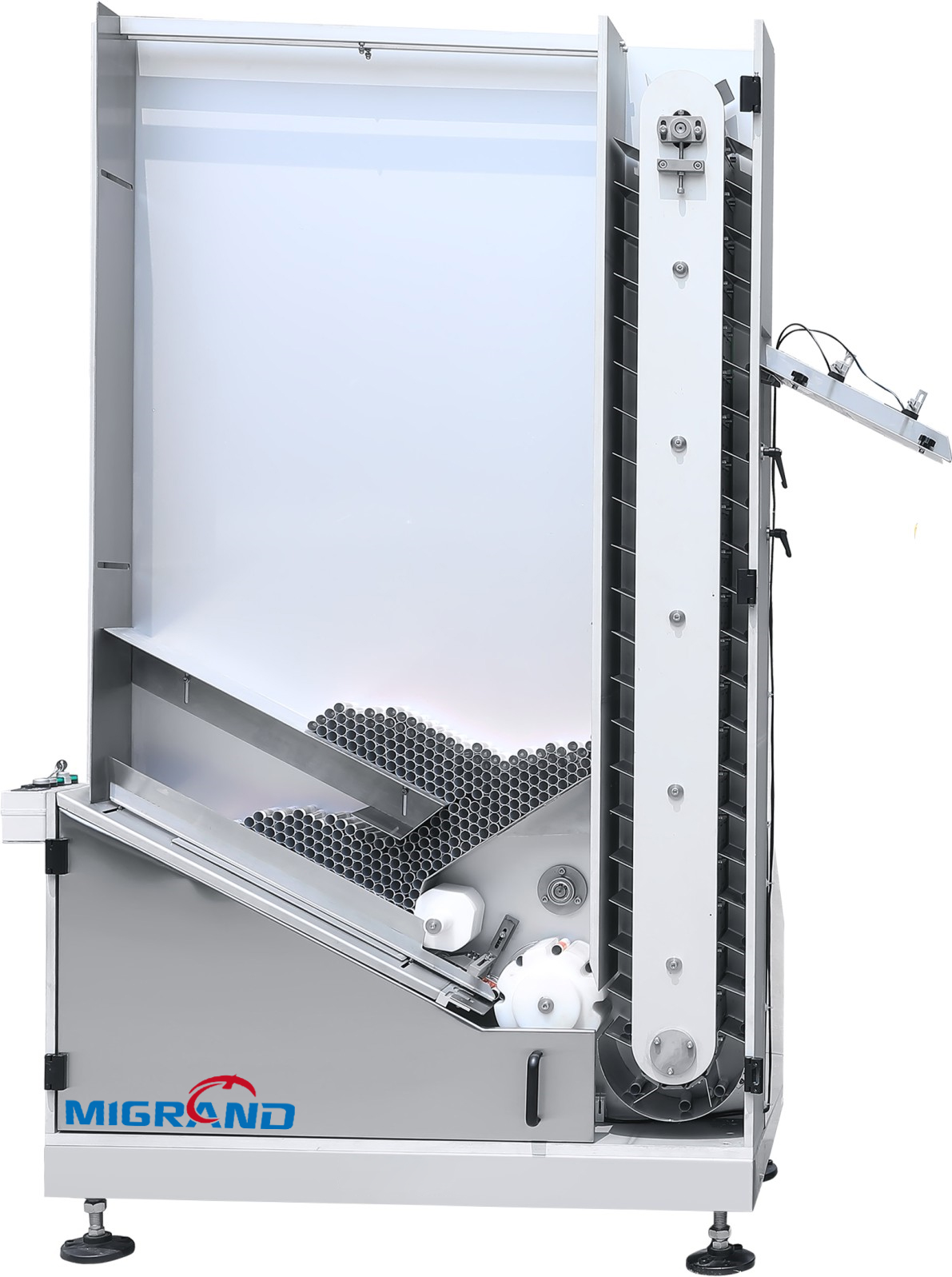

2. In order to cooperate with the high operation speed, the tube feeder is equipped with a large-capacity, the full capacity can reach 3000 tubes (in 19mm). It reduces tube feeding times, and the feeding height is suitable to operate.

3. Equipped with a plunger feeding pump, which is connected with the barrel through a stainless steel pipeline to achieve automatic feeding.

2700*2100*2100mm

It is equipped with a floor-mounted tube feeder with a round roller pipe.

1. Parameters:

| Configuration Standard | Technical Parameters | Remarks |

n Basic instructure |

| Working Area | (about)45㎡ |

|

| Whole Machine (L×W×H) | 2758×2260×2199mm |

|

| Integrated Structure | Convey belt between tube loading machine and main machine |

|

| Weight | (about)3400Kg |

|

n Machine case body |

| Frame Under Platform | Square Stainless Steel |

|

| Case Body Material | 304 |

|

| Opening Mode of Safety Guard | Handle Door |

|

| Safety Guard Material | PC |

|

| Frame Below Platform | Steel |

|

| Case Body Shape | Round-corner Square Shape |

|

n Power, Main Motor etc. |

| Power Supply | 50Hz/380V 3P |

|

| Servo Motor | 16KW |

|

| Vacuum Pump | 1KW |

|

n Production Capacity |

| Speed | 200/min(max) |

|

| Filling Range | 2-200ml |

|

| Filling Precision | ≤±0.5% |

|

| Position Accuracy | <1mm |

|

| Suitable Tube Length | 80-200mm |

|

| Suitable Tube Diameter | 12-35mm |

|

n Pneumatic Control System |

| Pneumatic Component | FESTO |

|

| Working Pressure | 0.6MPa |

|

| Compressed Air Consumption | 0.4m³/min |

|

2、Function introduction

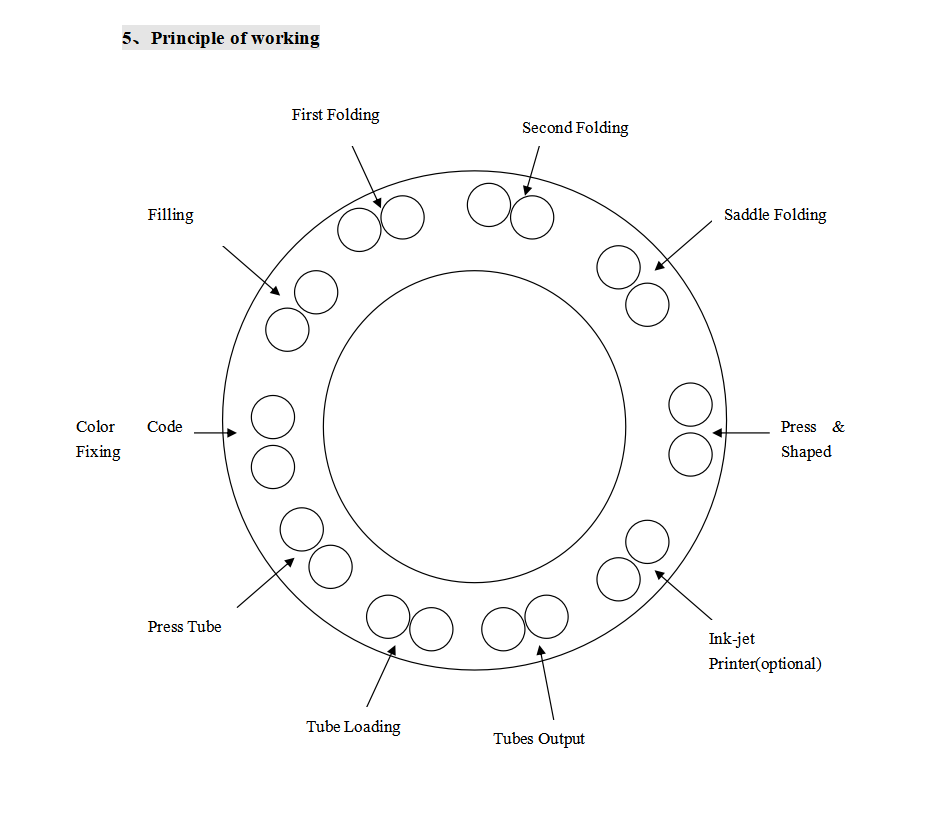

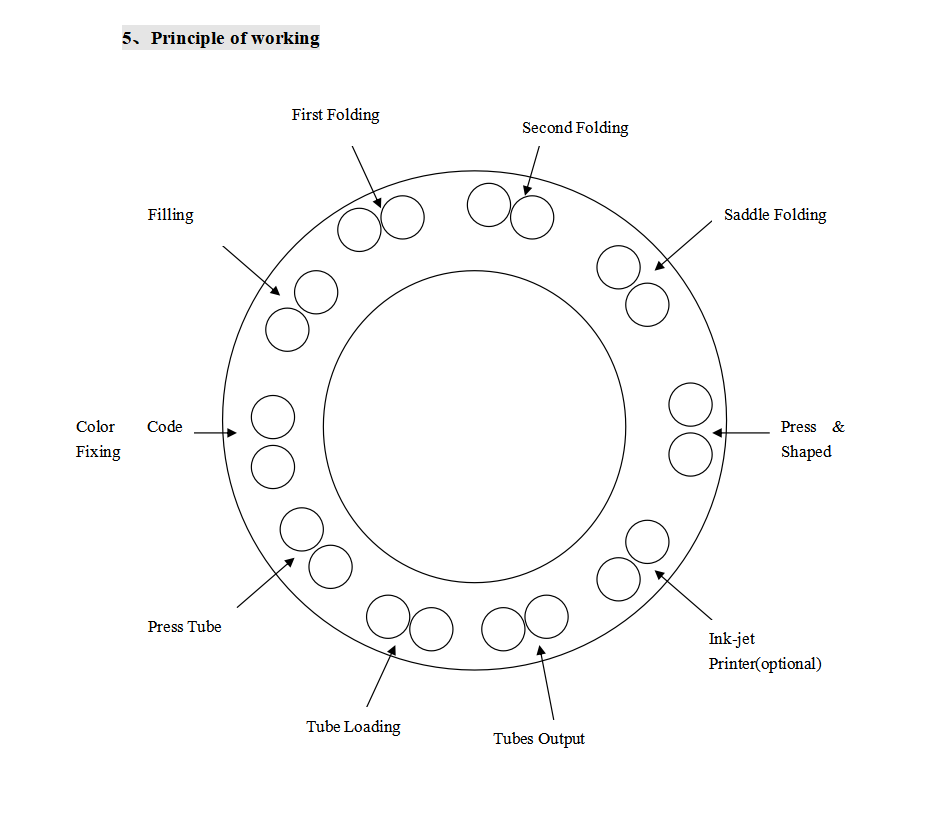

1、The machine is a 10-station turntable rotary type, and each station is equipped with two cup holders with German ELAU system plus Alpha reducer.

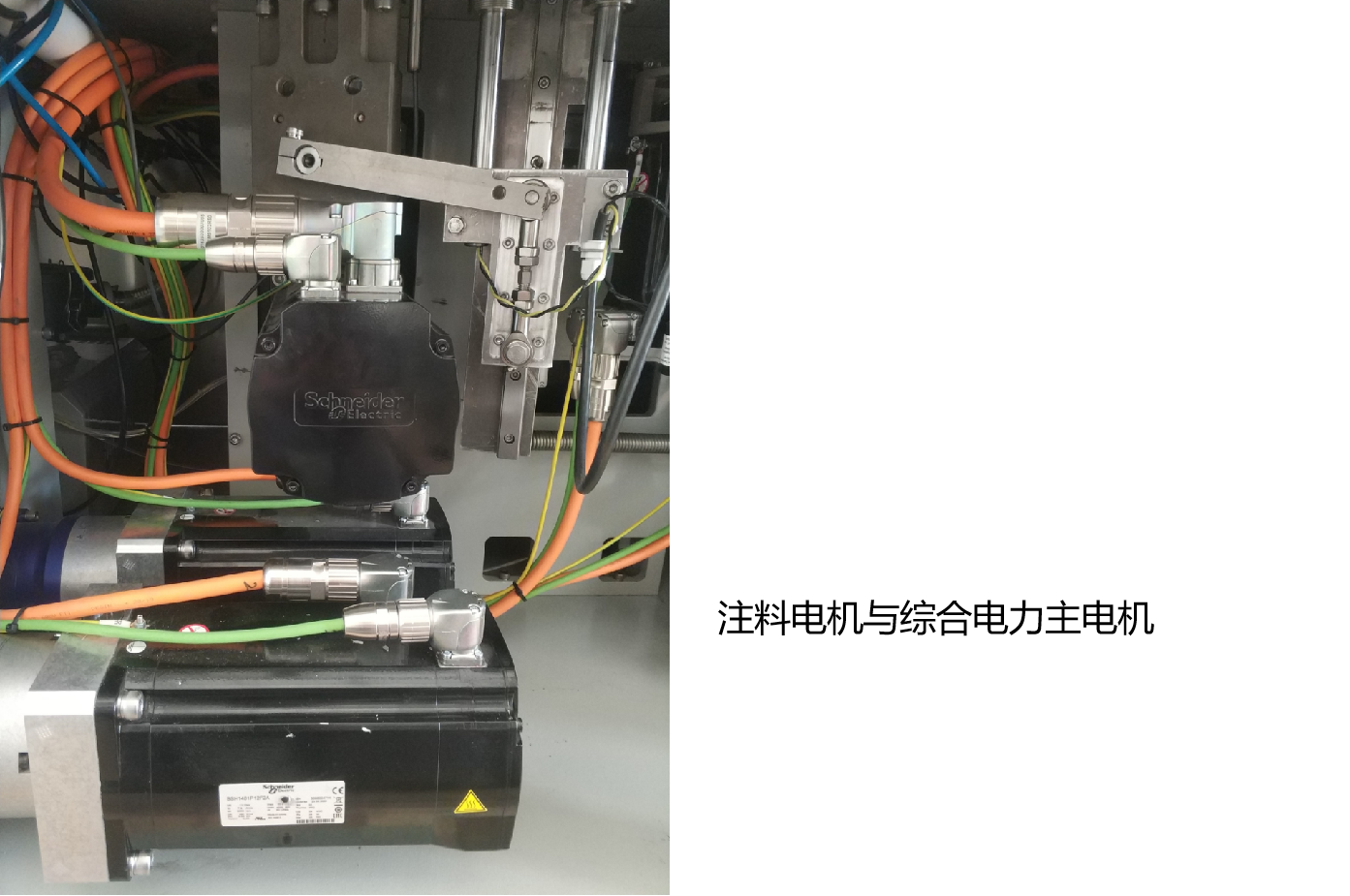

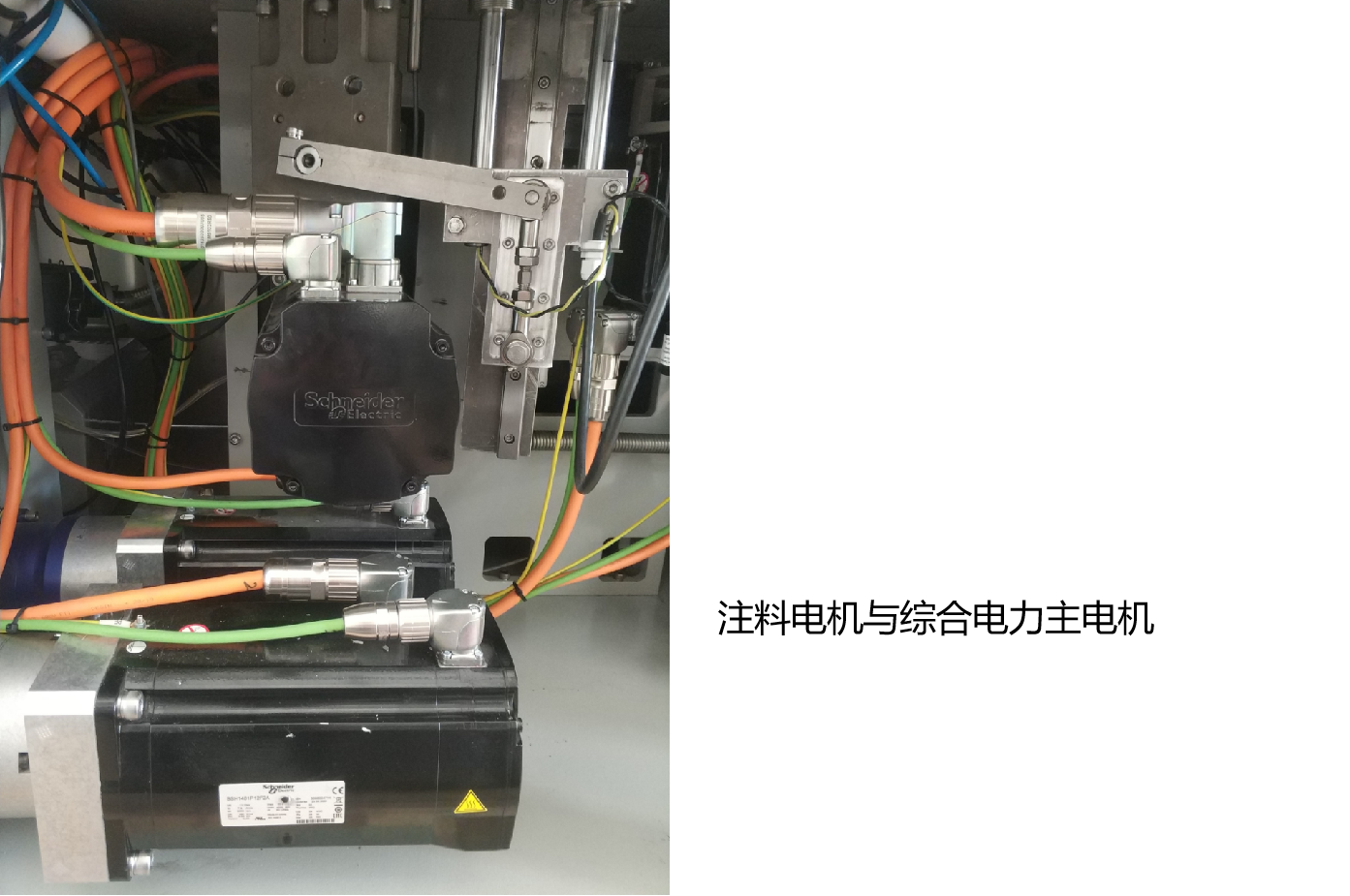

2、Servo System

The whole machine adopts SCHNEIDER PacDrive full servo control system, including 7 sets of servo motors and drivers.

Features efficient and energy-saving operation of the whole machine.

1 set, intermittent movement of rotary working turntable;

(2+3) sets, two mark alignment servo control systems;

(4+5) sets, two filling servo control systems;

6 sets, servo control system for the movement of the filling nozzle in the pipe when filling;

7 sets, main drive servo control system (all other power sources);

3、Tube feeding

Vacuum pump generates negative air pressure, so the handle sucks tubes and puts them precisely into the cores. Double tubes feeding at one time.

4、Inverted tube blowing and suction

The station is multifunctional, such as tube inside cleaning, tube detection, inverted tube detection, etc.

5、Positioning

Eye mark detection station with servo system and high-end sensor (Sick) cooperation, to ensure accurate positioning (error ≤±1mm).

6、Tube filling alignment

adopts high-reliability electromagnetic suction system for rapid tube cup positioning in high-speed operation, ensure tight binding during rotation and easy separation when disconnect.

7、Filling

Double-head filling, the nozzle adopts flexible in-cut filling mode without tailing and dripping, to ensure accurate filling.

85L filling barrel with volumetric filling metering system: adopts two sets of high-precision servo systems to control the filling, and the touch screen for filling volume adjustment.

Moveable electric forklift for lifting barrel

Filling motor and integrated electric master

Automatic feeding: feeding pump + ultrasonic sensor

Discharge

The pipe connecting the material barrel and feeding nozzle is made of food-grade multi-layer pipeline, and the parts in contact with the material is made of PTFE. It can withstand -40℃~260℃ and can be cleaned at high temperature.

The barrel, valve, piston sleeve, connecting pipe and feeding nozzle are all connected by clamps. It is simple to operate, disassemble, clean, and assemble aseptically.

8、Folding

German IWK: Saddle Folding

9、Date coding

Double-sided or single-sided embossing, legible and complete. Standard text: 3*1.8mm, can be flipped.

10、Defective tube rejecting:

tube with wrong mark;

2. empty tube without mark;

3. tube unfilled; 4. tube deformed.

11、Finished products discharge

The finished tubes are transported to the next process through the conveyor belt with tube tail out firstly.

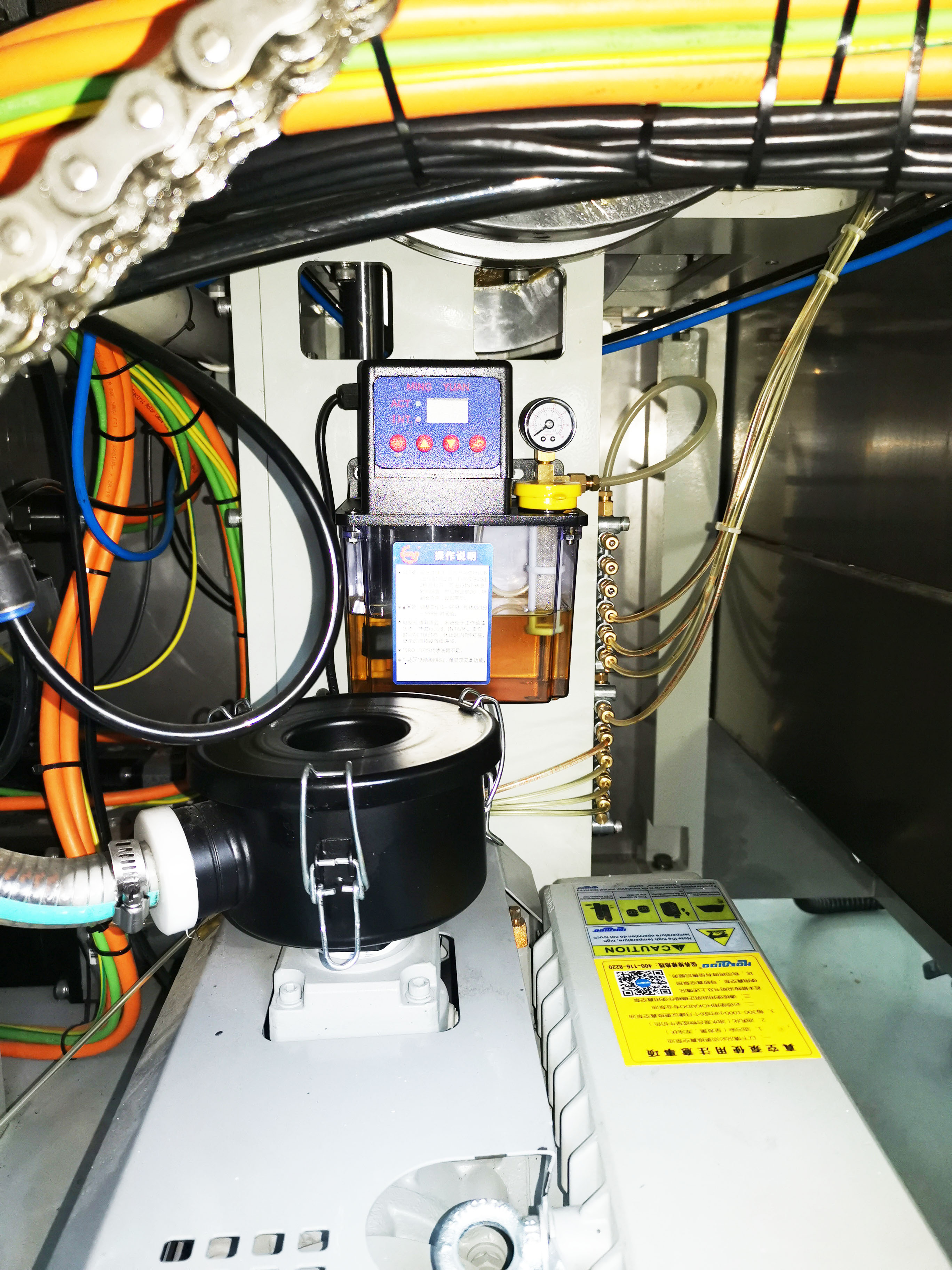

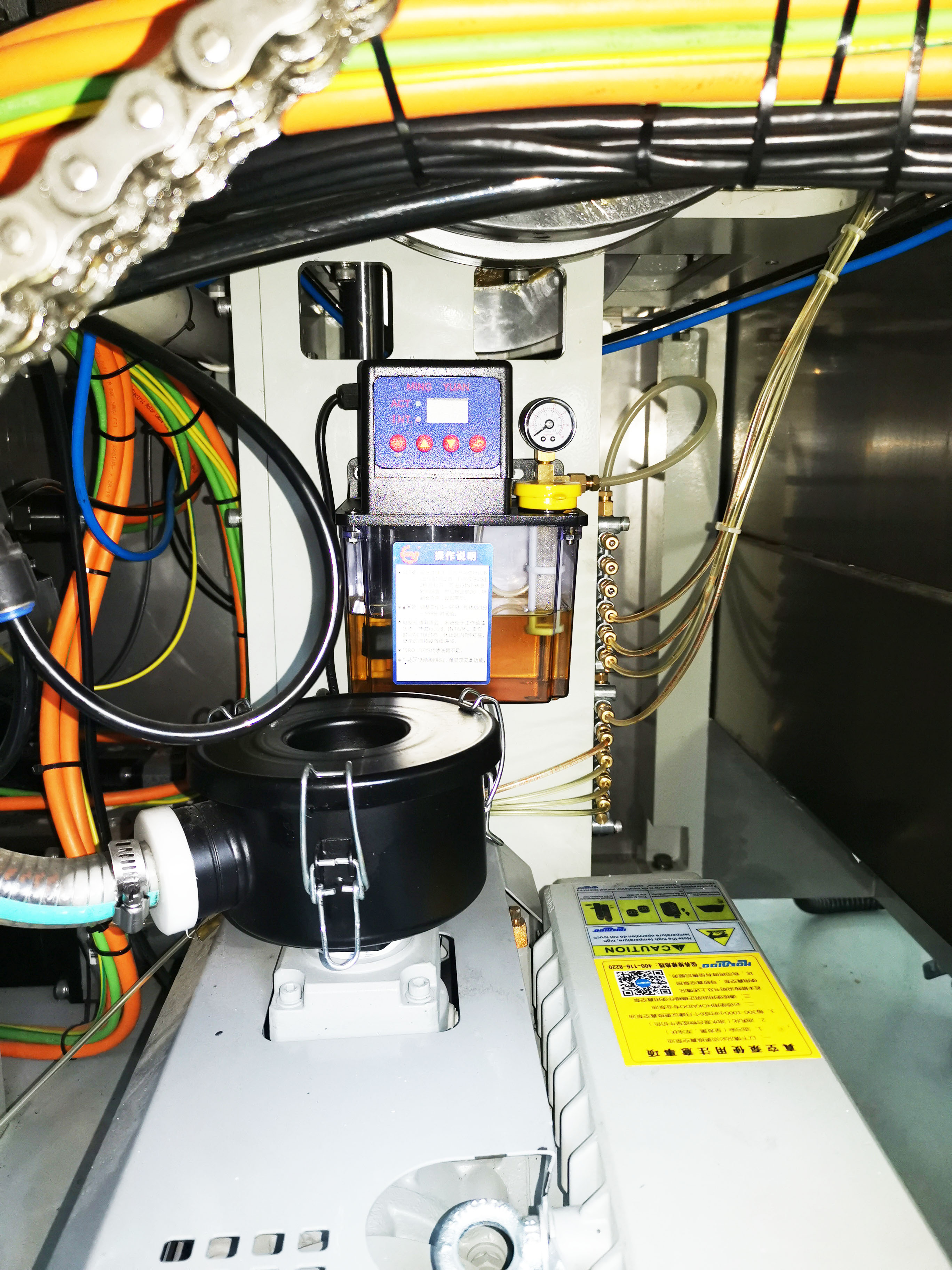

12、Automatic lubrication system:

According to lubrication requirements of the machine parts, the system regularly lubricates regularly according to the setting values, so as to reduce wear to prolong the service life, and reduce labor intensity. The system is safe and reliable, the lubrication points are not affected by external factors.

13、Electric cabinet

Automatic mode and manual mode, PLC-LMC201 series

14、Tube feeder

Large capacity, full capacity is up to 3000 tubes (in 19mm). the operating height is appropriate for saving working intensity. Can be ommunicated with the master for automatic operation start and stop.

Company Information

ABOUT US

Hunan Grand Packing Machinery Co.,Ltd is specialized in the pharmaceutical and packing machinery for more than 10 years, such as plastic ampoule forming filling and sealing machine, capsule filling machine, blister packing machine, strip packaging machine, cartoning machine etc. We have provided services and machines to many different countries and regions in the whole world, such as Indonesia, Thailand, Malaysia, Philippines, New Zealand, Korea,the Middle East area, Poland, Belgium, France, UK, Greece, Italy, Turkey, USA, central and south America such as Trinidad and Tobago,Mexico, Brazil, Russia, Ukraine, UZ, Tunisia, Algeria, Morroco etc. And we always gain the good reputation from customer both from the machine quality and after sales service.

Our Service

1.We will dispatch engineers to your site for machine installation and commissioning, and also do the training for your technicians.

2.We makes guarantee of the machine for 12 (twelve) months. During this Warranty period, the seller will provide free spare parts that cause by the machine’s quality within 10 days by fast courier upon receipt of buyer’s notice.(we will also provide one set of spare parts /wear &tear parts to customer along with the shipment of the machine.

3.We warmly welcome the suggestions from customer to make us grow better and produce better machine along with providing better service to customer, and create more value for customer.

4.Before placing the order or before shipping, welcome to our factory to take a visit to inspect our machine. we will pick you up in the airport or train station and arrange your following schedule in our city to bring you a nice journey during this visit.

English

English